Dymag, a world leader in lightweight wheels for the automotive industry, and its strategic partner, composites material specialists Hankuk Carbon, are working with Hyundai on the development of advanced new carbon hybrid wheel technology for the car maker’s N Performance products.

The first result of the collaboration between Dymag and Hankuk Carbon, the new wheel technology further cements Dymag’s position as a leading OEM partner for the global automotive industry, and marks the start of a relationship with Hyundai, enabling the wider adoption of Dymag’s cutting edge innovation, which delivers significant dynamic enhancements for high-performance vehicles.

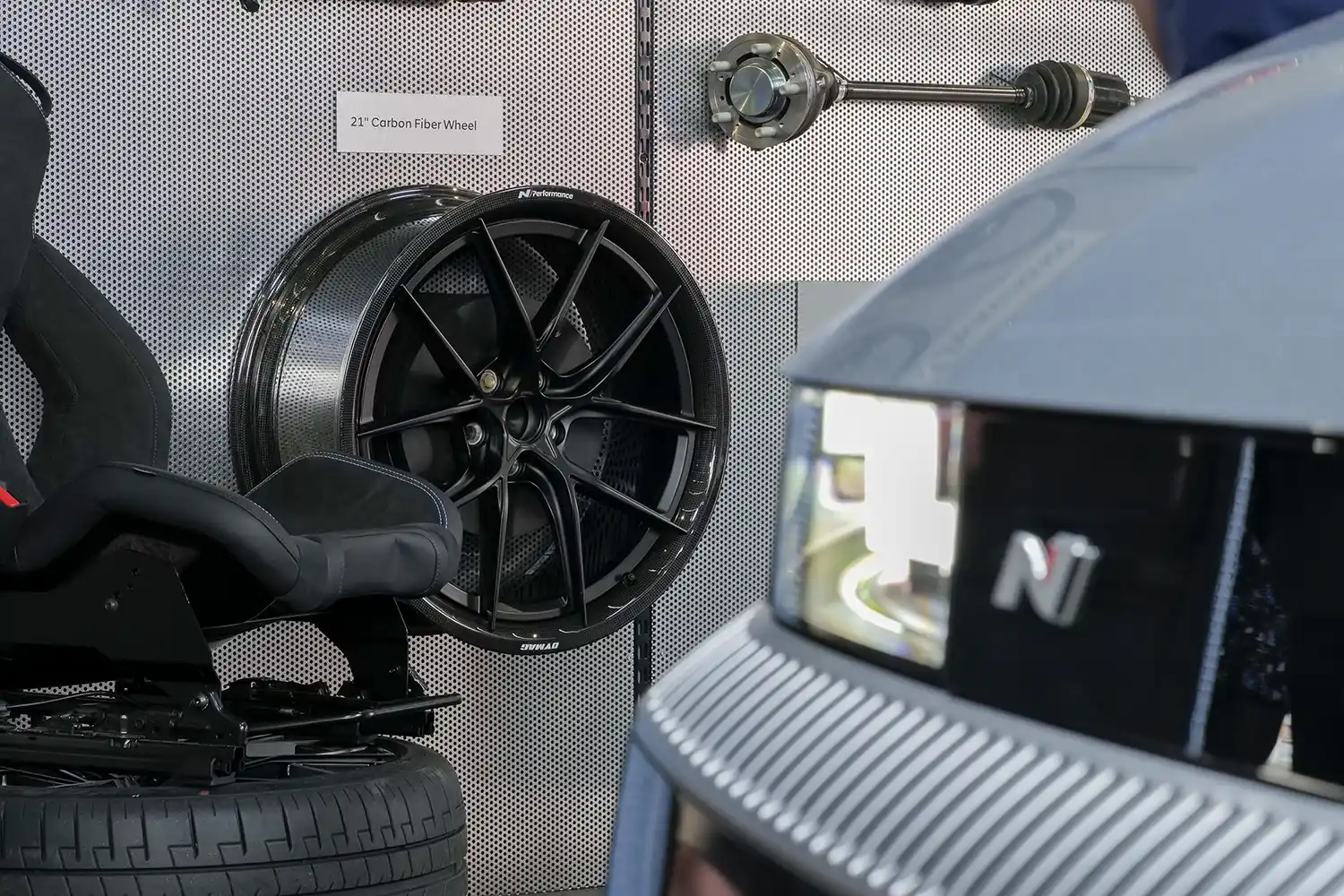

A prototype of a new jointly-developed N Performance carbon hybrid wheel was unveiled on Hyundai’s stand at the recent Goodwood Festival of Speed, where the company also debuted its IONIQ 5 N hot crossover.

Bespoke designed and developed with Hyundai, full specifications of the new wheel will be revealed in the coming months. Dymag is also in advanced stages with multiple car makers, with further original equipment supply agreements set to be announced soon.

Blending a composite outer rim, made from carbon fibre, with a precision-machined forged metallic centrepiece, Dymag’s proprietary carbon hybrid wheel expertise realises the best of both materials, with weight savings over a traditional cast aluminium wheel of between 40% and 50%. In addition to significantly reduced unsprung mass, carbon hybrid wheel technology also reduces rolling inertia and offers improved stiffness and strength.

Tom de Lange, CEO of Dymag said: “We are delighted we are working with Hyundai on the development of advanced, lightweight carbon hybrid wheels for its N Performance products. The first result of the collaboration between Dymag and Hankuk Carbon, the new wheel technology further cements Dymag’s position as a leading OEM partner for the global automotive industry.

“This is the start of what we hope is a long and fruitful relationship with Hyundai, which will bring our game-changing technology to a wider audience of global automotive customers. Carbon hybrid wheels from Dymag bring many benefits for high-performance vehicles, with very low capital expenditure for car makers thanks to our patented technology and lean production methods. We look forward to announcing further OEM agreements very soon.”

Hankuk Carbon Chairman Mr. Moonsoo Cho said: “We are very excited by this great starting point of our relationship with Dymag. Working with Hyundai makes us all very proud and will bring Dymag’s carbon hybrid wheel technology, which offers significant performance – and aesthetic – benefits to high-performance vehicles, to a wider audience. Our collaboration with Dymag will continuously grow to meet and exceed the requirements of our global automotive partners.”

Leading advanced wheel design since 1974, Dymag has unrivalled heritage and was the first in the world to commercialise carbon hybrid automotive wheels in 2004. Designed for high-performance vehicles, from sports cars to SUVs and pickups, the patented carbon hybrid wheel delivers multiple gains for OEMs, the aftermarket and customers alike.

In addition to lower unsprung mass and inertia, gyroscopic force is also reduced, improving steering feel and handling.

Strength and durability are also improved over equivalent alloy wheels or full carbon wheel, a carbon hybrid wheel enhance safety by offering the ability to bend and spring back in the event of an unusually high load or sharp impact – in contrast to one-piece aluminium wheels which can permanently deform or shatter. Dymag’s unique designs are also proven and tested to all worldwide OEM standards. What’s more, carbon fibre’s inherent harmonic characteristics also reduce Noise Vehicle Harshness (NVH).

Carbon hybrid wheels also bring aesthetic advantages for OEMs compared to one-piece carbon fibre wheels; a forged aluminium or magnesium centrepiece offering greater design flexibility than a solid carbon fibre wheel, which can be changed without incurring expensive re-tooling costs. The carbon rims themselves also require low upfront investment and new sizes can be produced very quickly due to Dymag’s patented design and production techniques.

Dymag offers a full range of 18-to-23-inch carbon hybrid wheels, to which it will add new 24-inch and 25-inch examples later this year. Key investment into Dymag comes from strategic partner, Hankuk Carbon, a leading manufacturer of advanced carbon materials.

Its investment and expertise is accelerating the global mass production of Dymag’s wheel technology, and the company is in advanced stages with multiple global OEMs regarding further lightweight wheel supply agreements.