EQA is the name of the new entry-level model to the all-electric world of Mercedes-EQ vehicles. The electro-aesthetics of its design are indicative of the Progressive Luxury of the Mercedes-EQ brand. Smart assistants support the driver in many areas: for example with respect to accident avoidance, the anticipatory and therefore particularly efficient operating strategy, and Navigation with Electric Intelligence. In addition, the car features various exceptional Mercedes-Benz functions, such as ENERGIZING Comfort and MBUX (Mercedes-Benz User Experience). The EQA is a member of the successful compact car family from Mercedes-Benz. A close relation of the GLA, it delivers all the thrilling characteristics of that vehicle, combined in this case with an efficient electric powertrain. The new EQA is being built in Rastatt (Germany) and Beijing (China). The battery systems for the EQA are supplied by the Mercedes-Benz subsidiary Accumotive in Kamenz. The battery factory in Jawor, Poland, is also preparing to produce battery systems for the compact Mercedes-EQ models. From the spring of 2021, the electric SUV will be available from the European dealerships.

“Mercedes-EQ aspires to take the lead in the field of electric drive systems and vehicle software. To this end, we have defined some ambitious product development goals and resolved to push forward with the accelerated market introduction of new technologies”, says Markus Schäfer, Member of the Board of Management of Daimler AG and Mercedes-Benz AG; responsible for Daimler Group Research and Mercedes-Benz Cars COO. “The new EQA allows us to show the way we envisage e-mobility as tailored to the needs of our customers. We will offer a whole family of EQA models, with output ranging from 140 through to more than 200 kW, and with front-wheel as well as all-wheel drive. And for those for whom the issue of range is particularly important, our portfolio will in due course also include a special version of the EQA with a radius of more than 500 kilometres according to WLTP. The EQA proves that, by using a tried and tested architecture, it is possible to achieve an excellent compromise between performance, costs and time to market.”

The EQA is being launched as the EQA 250 (combined electric consumption: 15.7 kWh/100 km; combined CO2 emissions: 0 g/km) with 140 kW and a range according to NEDC of 486 kilometres. The “double-decker” lithium-ion battery, which sits as a structural element within the underbody of the vehicle, has an energy content of 66.5 kWh. In order to meet the high standard of noise and vibration comfort that is such a hallmark of the brand, complex measures have been taken to isolate the electric powertrain from the chassis and body. Numerous damping measures enhance this effect.

The EQA 250 will be available in Germany at prices from 47,540.50 euros. Based on the net list price of 39,950 euros, customers can avail themselves of the environmental bonus of 6000 euros offered by the federal government and 3000 euros from Mercedes-Benz as the manufacturer.

“Progressive design and intuitive operation are two of the highlights of the EQA. With this car, for the first time we are offering our customers an all-electric Mercedes in the compact segment with an extensive range that ensures its viability in everyday use. As such, the new EQA is an important vehicle along our path towards the electrification of all our vehicle segments”, says Britta Seeger, Member of the Board of Management of Daimler AG and Mercedes-Benz AG, responsible for Mercedes-Benz Cars Marketing and Sales.

“Thanks to MBUX, our vehicles these days have become mobile assistants. With the EQA we take things a step further: clever support functions such as Navigation with Electric Intelligence are integrated here into MBUX, making it even easier to use”, emphasises Sajjad Khan, Member of the Board of Management of Mercedes-Benz AG, CASE. “Furthermore, the EQA shows how we have been able to reconcile a state-of-the-art and sustainable electric drive system with the Mercedes-Benz core value of Safety.”

Electro-aesthetics of the design signalise Progressive Luxury

The Mercedes-Benz EQA features the black panel radiator grille with central star that is the hallmark of Mercedes-EQ. A further distinctive design feature of the all-electric world of Mercedes-EQ vehicles is the continuous light strip at front and rear. A horizontal fibre-optic strip connects the daytime running lights of the full-LED headlamps, ensuring a high level of recognisability both in daylight and at night. The inside of the headlamps is finished to a high level of quality, detail and precision. Blue colour highlights within the headlamp reinforce the signature Mercedes-EQ appearance. The LED tail lamps merge seamlessly into the tapered LED light strip, thus underlining the impression of width in the rear view of the EQA. The licence plate has also been relocated to the bumper. Exclusive to this model are light-alloy wheels in a bi- or tri-colour design, up to 20 inches in size, in some cases with rosé gold-coloured or blue decorative trim.

“Progressive Luxury in its sportiest form. An all-electric SUV designed for the sustainable mobility of the future has been born, in the shape of the compact, modern EQA”, says Gorden Wagener, Chief Design Officer of Daimler AG. “The perfect proportions of the exterior and a spectacular interior set new standards.”

An indication of the electric character in the interior of the EQA is provided, depending on the design and equipment line, by a new-style back-lit trim element and rosé gold-coloured decorative trim on the ventilation outlets, seats and the vehicle key. The Edition 1 special model additionally features perforated leather seats, through which blue fabric can be seen. The instruments, with their electric car-specific displays, pick up on the same colour scheme with rosé gold-coloured and blue highlights.

The seating position is high and upright, as is typical for an SUV – making it not only comfortable for getting in and out, but also good in terms of all-round visibility. Utility value was one of the general focuses during development. The rear seat backrest is 40:20:40 split-folding.

Efficiency is the key factor, from the aerodynamics through to Navigation with Electric Intelligence

With a Cd value from 0.28, the EQA achieves an excellent result. The frontal area A totals 2.47 m2. Among the most important aerodynamic measures are the completely closed cooling air control system in the upper section, the aerodynamically efficient front and rear aprons, a very smooth, almost completely enclosed underbody, specially optimised Aero wheels and specifically adapted front and rear wheel spoilers.

The standard heat pump forms part of the sophisticated thermal management system. With its numerous innovative details, such as the reuse of the waste heat from the electric drive system, the system is configured for exceptional efficiency and thus maximum range. It is also possible to set the pre-entry climate control for the interior of the EQA before starting. This function is controlled directly from the MBUX infotainment system or via the Mercedes me App.

Adding to the general ease of using the EQA on a day-to-day basis is the standard feature of Navigation with Electric Intelligence. This calculates the fastest route to the given destination. On the basis of continual range simulations, the system makes allowance for any necessary charging stops as well as for numerous other factors, such as the topography and the weather. It is also able to react dynamically to changes, for instance in the traffic situation or personal driving style.

With Mercedes me Charge, customers have access to what is currently the world’s biggest charging network: this currently comprises more than 450,000 AC and DC charging points across 31 countries. Mercedes me Charge allows Mercedes-EQ customers convenient use of the charging stations of various providers, while they also benefit from an integrated payment function with simple billing processes.

By means of high-quality certificates of origin, Mercedes-Benz guarantees that energy from renewable resources is fed into the grid for charging current sourced via Mercedes me Charge. Mercedes me Charge enables customers to charge at more than 175,000 public charging points throughout Europe; Mercedes-Benz ensures a subsequent offset with green power

Intelligent driving assistance systems with cooperative support from the driver, exceptional crash safety

Included as standard on board are Active Lane Keeping Assist and Active Brake Assist. In many situations the purpose of the latter is to prevent a collision by autonomous braking, or to mitigate its consequences. The system is also able to brake for stationary vehicles and crossing pedestrians at typical city speeds. The enhanced functions of the Driving Assistance Package include, for example, the turning manoeuvre function, the emergency corridor function, the exit warning function alerting the driver to approaching cyclists or vehicles, and a warning when pedestrians are detected near zebra crossings.

The EQA is also a true Mercedes when it comes to passive safety. On the basis of the robust structure of the GLA, the body of the EQA was adapted to meet the particular demands that face an electric car. The battery sits within a frame made out of extruded sections. This takes on a structural function which until now was handled by the cross members in the underfloor. A battery guard in the front area of the battery is able to prevent the energy storage unit from being pierced by foreign objects. Naturally the EQA also had to go through the brand’s normal and very thorough crash test programme. Stringent requirements for the battery and all components carrying electrical current also apply.

Superior level of equipment, instruments with displays specific to Mercedes-EQ

Included as standard is the intuitively operated MBUX infotainment system (Mercedes-Benz User Experience). MBUX can be individually configured with the help of various options. Key advantages of the system: the powerful computer, brilliant screens and graphics, customisable presentation, full-colour head-up display (optional equipment), navigation with augmented reality (optional equipment), learning software and voice control activated by the keyword “Hey Mercedes”.

The Mercedes-EQ tile in the media display can be used to call up menus relating to charging options, electrical consumption and energy flow. The right-hand display within the instrument cluster is a wattmeter rather than a rev counter. The upper section shows the percentage of power used, the lower section the recuperation. The left-hand instrument can be used to show whether the destination can be reached without an interim charging stop. The colours change according to the driving situation: During a boost process, for example, the display changes to white. Depending on mood, or to match the particular interior, the user has a choice of four different styles. The Progressive variant includes a special Mercedes-EQ colour scheme

The comprehensive standard specification of the EQA includes such features as LED High Performance headlamps with Adaptive Highbeam Assist, the EASY-PACK tailgate with electrically operated opening and closing, 18-inch light-alloy wheels, ambient lighting with 64 colours, a double cup holder, luxury seats with four-way adjustable lumbar support, a reversing camera for added convenience and a better overview when manoeuvring, and a multifunction sports steering wheel in leather. The new model can be personalised with either of the two design and equipment lines AMG Line and Electric Art, as well as with the Night Package.

Trailer coupling with quick and easy unlocking

A trailer coupling with ESP® trailer stabilisation is available as an option for the EQA. A particularly convenient feature is the electric unlocking system for the ball coupling. The unlocking switch and indicator lamp are located within the tailgate. Once the ball coupling has been unlocked it can either be pivoted out or, when not in use, pivoted back behind the bumper trim. The towing capacity (unbraked/ braked) of the EQA 250 is 750 kilograms, the tongue weight 80 kilograms. The trailer coupling has been approved for use with a bicycle rack. The all-wheel-drive models will offer an even higher towing capacity.

Unmistakable day and night

The electro-aesthetics of the design are indicative of the Progressive Luxury of the Mercedes-EQ brand. The EQA features the black panel radiator grille with central star that is a hallmark of the brand. A horizontal fibre-optic strip connects the daytime running lights of the full-LED headlamps, ensuring a high level of recognisability both in daylight and at night. The inside of the headlamps is finished to a high level of quality, detail and precision. Blue colour highlights within the headlamp reinforce the signature Mercedes-EQ appearance. In its AMG Line guise the EQA is fitted with a radiator grille with a glossy black frame and a chrome-plated twin louvre as an inlay in the black panel. At the rear end, too, the designers made sure to include features characteristic of Mercedes-EQ: The LED tail lamps merge seamlessly into the tapered LED light strip, thus underlining the impression of width in the rear view of the EQA. The licence plate has also been relocated to the bumper. Light-alloy wheels in a bi- or tri-colour design, up to 20 inches in size, are available. The exclusive details include rosé gold-coloured or blue decorative trim.

As the all-electric sibling of the GLA, the EQA enjoys the same powerful overall proportions with short overhangs front and rear. The front section flows over the A-pillar into the visually compact greenhouse. The powerdomes hinted at in the bonnet, like the flush wheels, underscore the car’s self-confident stance. Further distinctive features include the powerful shoulders of the bodywork and the coupé-like lines of the side windows. The pronounced contours of the sides add a certain dynamic elegance and offer an interesting interplay of light and shadow.

The side and rear views are characterised by the muscular shoulders of the vehicle. The front wing boasts a badge in high-gloss black with EQA lettering in blue. The doors reach over the sills, thereby on the one hand improving ease of access, while at the same time keeping the door frames (and thus also the occupants’ trousers) free of dirt and improving impact protection in the event of a side collision. All-round protective cladding adds structure to the overall proportions and emphasises the vehicle’s off-road character, as does the simulated underride guard at the front and rear.

The multi-section design of the rear lights means that the opening of the load compartment could be made wider, thus facilitating loading, while the impression of width at the back is enhanced. The licence plate has also been relocated to the bumper in typical Mercedes-EQ style. Further details with a distinctly practical purpose include the integrated roof rails in polished aluminium. The reversing camera, provided as standard, is integrated into the automatically pivoting Mercedes-Benz star.

Progressive Luxury: characterised by blue and rosé gold-coloured elements

There are numerous pointers to the electric character of the EQA in the interior. Depending on the design and equipment line, these include a new-style back-lit trim element and rosé gold-coloured decorative trim on the ventilation outlets, seats and the vehicle key. The Edition 1 special model additionally features perforated leather seats, through which blue fabric can be seen. The instruments, with their electric vehicle-specific displays, pick up on the same colour scheme with rosé gold-coloured and blue highlights.

The dashboard consists of a basic volume, which features optical “cut-outs” in the driver and front passenger area. The cut-out on the driver’s side is dominated by the free-standing display unit, which is available in two variants: with two 7-inch displays (17.78 cm) or in a Widescreen variant with two 10.25-inch displays (26 cm). On the passenger side, the cut-out area is finished with a trim element in what is called a spiral look. A spectacular effect, particularly at night, is delivered by the high-tech back-lit version of this trim in the Electric Art, AMG Line and Edition 1 models. The individual, transparent sections of the surface are illuminated from behind with the aid of fibre-optics. Depending on the equipment variant, the trim is also available in open-pore brown linestructure walnut wood, open-pore black lime wood or aluminium with light longitudinal grain (see also section on “The equipment”).

The round ventilation outlets, five of them in all, feature a high-quality turbine look with meticulously designed air guidance vanes. With Electric Art, the turbine blades in the outlets are rosé gold-coloured. This line is further distinguished by the use of titanium grey Artico leather in a combination with “Jalaya” rosé gold-coloured fabric. This also scores points in terms of sustainability: the fabric is made from recycled PET bottles. The seats also feature rosé gold-coloured piping.

In the Edition 1 model, ventilation outlets in Silver Shadow are framed by a blue air-control ring. The design of the leather seats in this special model is particularly complex: behind the neva grey leather is a blue fabric. Cyber-cut technology has been used to meticulously perforate the leather in order to allow the blue backing to show through. As a further distinctive feature, one of the two vehicle keys with Electric Art and Edition 1 is a rosé gold-coloured/high-gloss black design key.

Spacious, practical and variable

The seating position is high and upright, as is typical for an SUV – making it not only comfortable for getting in and out, but also good in terms of all-round visibility. The rear seat backrest is 40:20:40 split-folding.

Instruments with displays specific to Mercedes-EQ and special colour scheme

Included as standard is the intuitively operated MBUX infotainment system (Mercedes-Benz User Experience). MBUX can be individually configured with the help of various options. Key advantages of the system: the powerful computer, brilliant screens and graphics, customisable presentation, full-colour head-up display, navigation with augmented reality and learning software and voice control activated by the keyword “Hey Mercedes”.

The information in the instrument cluster and on the media display is easily legible on the large, high-resolution screens. An emotive presentation underlines the comprehensibility of the intuitive control structure and offers brilliant graphics in superb visual quality. The Mercedes-EQ tile in the media display can be used to call up menus relating to charging options, electrical consumption and energy flow. The right-hand display within the instrument cluster is a wattmeter rather than a rev counter. The upper section shows the percentage of power, the lower section the recuperation. The left-hand instrument can be used to show whether the destination can be reached without an interim charging stop. The colours change according to the driving situation: during a boost process, for example, the display changes to white.

Depending on mood, or to match the particular interior, the user has a choice of four different styles. The Progressive variant includes a special Mercedes-EQ colour scheme:

- Modern Classic is the evolution of the classic display style in an elegantly light and exquisite materiality.

- Sport has a high-tech turbine look featuring a sporty contrast of black/yellow.

- Progressive represents a modern interpretation of an instrument cluster in the digital display world. In the interests of reducing the display to what is strictly necessary and in order to allow focused intake of information, the display values of the round instruments for speed and power are displayed dynamically only in the required range in each instance. In the EQA the colour scheme here is pure blue/rosé gold-coloured.

- Discreet mode greatly reduces the information and thereby helps the driver to relax.

At an exceptionally high level

Even the base model of the EQA is already generously equipped, and is based on the Progressive line found in the GLA. The new model can be personalised with either of the two design and equipment lines Electric Art and AMG Line, as well as with the Night Package. For the first year after the market launch, an Edition 1 special model will be available. This includes, for example, special cyber-cut perforation of the leather that allows the shimmering blue fabric underneath to show through.

The level of equipment in the base-model EQA is already at an elevated level: the standard specification includes such features as LED High Performance headlamps with Adaptive Highbeam Assist, the EASY-PACK tailgate with electrically operated opening and closing, 18-inch light-alloy wheels, ambient lighting with 64 colours, a double cup holder, luxury seats with four-way adjustable lumbar support, a reversing camera for added convenience and a better overview when manoeuvring, and a multifunction sports steering wheel in leather. Also included as standard are the intuitively operated infotainment system MBUX (Mercedes-Benz User Experience) and the Navigation with Electric Intelligence system.

Night Package and Edition 1: even more opportunities for personalisation

The Night Package comprises the following elements: claddings in black with inserts in high-gloss black, exterior mirror housings painted black, shoulderline trim strip and window line trim strip in high-gloss black, roof rails in matt black, heat-insulating tinted glass from the B-pillar back; 45.7 cm (18-inch) light-alloy wheels in a 5-twin-spoke design, painted black and with a high-sheen finish, simulated underride guards in the front and rear aprons in high-gloss black.

The Edition 1 is available for one year from the launch of the EQA. Its exterior features include the AMG black panel radiator grille, AMG bodystyling for the front and rear bumpers, shoulderline trim strip in chrome and 20-inch, rosé gold-coloured AMG multispoke wheels. A highlight in the interior is provided by neva grey leather seats, with blue fabric appearing through their cyber-cut perforations. The decorative topstitching in the door trim and the armrest, as well as the inner air control ring of the ventilation outlets are blue. The spiral-look trim element is back-lit. Special floor mats with Edition 1 lettering and blue piping round off the overall look.

Progressive Luxury with intelligence: ENERGIZING comfort control with PowerNap function

The Mercedes-BenzEQA uses its intelligent system to think for its passengers and pamper them: ENERGIZING comfort control links together various comfort systems in the vehicle, using lighting and musical moods plus a number of massage options to deliver a wide range of feel-good programmes. The ENERGIZING Package Plus is available as an option for the EQA. Special function of the EQA courtesy of its high energy reserves: during a short break in a journey e.g. at motorway services or a charging station, the PowerNap programme may be selected. The programme has three phases – falling asleep, sleeping, waking – and can enhance the performance of the driver and provide new energy.

Further programmes are Warmth, Joy, Comfort, Refresh and Vitality as well as Training (three training modes – muscle relaxation, muscle activation and balance – each with several exercises). The training can also be carried out while driving.

The ENERGIZING COACH recommends programmes according to the situation. If the Mercedes-Benz vivoactive® 3 smartwatch, the Mercedes-Benz Venu® smartwatch or another compatible Garmin® wearable is linked, personal values such as stress level or sleep quality optimise the precision of the recommendation. Via the Mercedes me App, the smartwatch sends vital data of the wearer to the vehicle, e.g. pulse rate, stress level and sleep quality. The aim is to ensure that the driver feels well and relaxed even during demanding or monotonous journeys. In addition, the pulse rate recorded by the integrated Garmin® wearable is shown on the media display.

ENERGIZING seat kinetics also benefit driver fitness. The system supports advantageous changes in the seating posture by means of minute movements of the seat cushion and backrest when on a journey. ENERGIZING seat kinetics is available in combination with electric seat adjustment with Memory function and with the ENERGIZING Package Plus.

URBAN GUARD: with theft notification and parking damage detection

In conjunction with Mercedes me, the two packages URBAN GUARD Vehicle Protection and URBAN GUARD Vehicle Protection Plus enable all-round monitoring of the parked vehicle. URBAN GUARD comprises an anti-theft alarm system, tow-away protection with visual and acoustic warning in the case of a detected change in position, an alarm siren, interior monitoring (triggers in the case of movements in the interior) as well as a preinstallation for theft and parking collision detection. In the case of the latter, the vehicle sensors register when the parked and locked vehicle is bumped or towed – or when someone attempts to break into the vehicle. If the service is active, the driver is informed via the Mercedes me App. By means of a push notification, he/she finds out how severe the parking damage is and in which area of the vehicle it occurred, for example. As soon as the vehicle is restarted, this information is also shown once on the media display.

In addition, URBAN GUARD Vehicle Protection Plus is able to pinpoint the location of stolen vehicles. In case of theft, this also makes it possible to recover the vehicle even if the thief has deactivated the vehicle tracking function, for example. This takes place in cooperation with the police.

Trailer coupling: with quick and easy unlocking

A trailer coupling with ESP® trailer stabilisation is available as an option for the EQA. A particularly convenient feature is the electric unlocking system for the ball coupling. The unlocking switch and indicator lamp are located within the tailgate. Once the ball coupling has been unlocked it can either be pivoted out or, when not in use, pivoted back behind the bumper trim. The towing capacity (unbraked/ braked) of the front-wheel-drive model is 750 kilograms, the tongue weight 80 kilograms. The trailer coupling has been approved for use with a bicycle rack. The all-wheel-drive models will offer an even higher towing capacity.

Efficient driving pleasure

The EQA is being launched as the EQA 250 (combined electrical consumption: 15.7 kWh/100 km; combined CO2 emissions: 0 g/km) with 140 kW and a range according to NEDC of 480 kilometres. The “double-decker” lithium-ion battery, which sits as a structural element within the underbody of the vehicle, has a usable energy content of 66.5 kWh. Further variants to meet specific customer requirements will follow. These will include on the one hand all-wheel-drive models with an additional electric powertrain (eATS), and on the other hand a version with a range of more than 500 kilometres (WLTP).

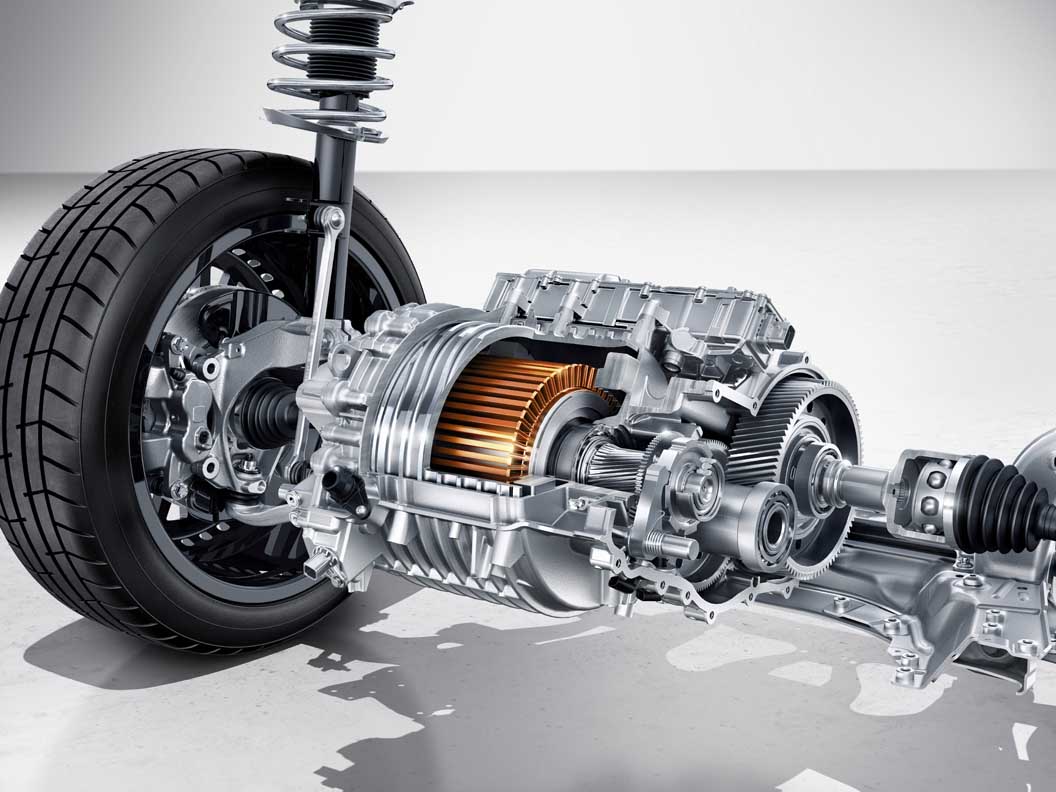

An asynchronous motor is used at the front axle. The electric motor, a fixed-ratio transmission with a differential, the cooling system and the power electronics form a highly integrated, very compact unit – the electric powertrain (eATS). The transmission ratio and gear wheels have been configured for the requirements of the front-wheel drive system.

The more powerful models include a further electric powertrain (eATS) at the rear axle featuring a redesigned, permanently excited synchronous motor. This is extremely compact in design. In a permanently excited synchronous motor, the rotor of the AC motor is studded with permanent magnets. The magnets – and thus the rotor – follow the rotating alternating current field in the winding of the stator. The engine is said to be synchronous, because the rotor turns at the same rate as the magnetic field of the stator. The rate is adjusted to the speed requirements of the driver in the frequency converters of the power electronics. The advantages of this design include the high power-to-size ratio, high level of efficiency and high output consistency.

The balance of performance between the front and rear axles in the 4MATIC versions is intelligently adjusted up to 100 times per second, depending on the driving situation. The Mercedes-EQ philosophy is to optimise consumption by using the rear electric motor as often as possible, while the asynchronous motor at the front axle generates only minimal drag losses in partial-load operation.

In overrun mode or during braking, the electric motors become alternators: their mechanical rotation is converted into electrical energy and used to charge the high-voltage battery – a process known as recuperation (for details see the next section on “Recuperation”).

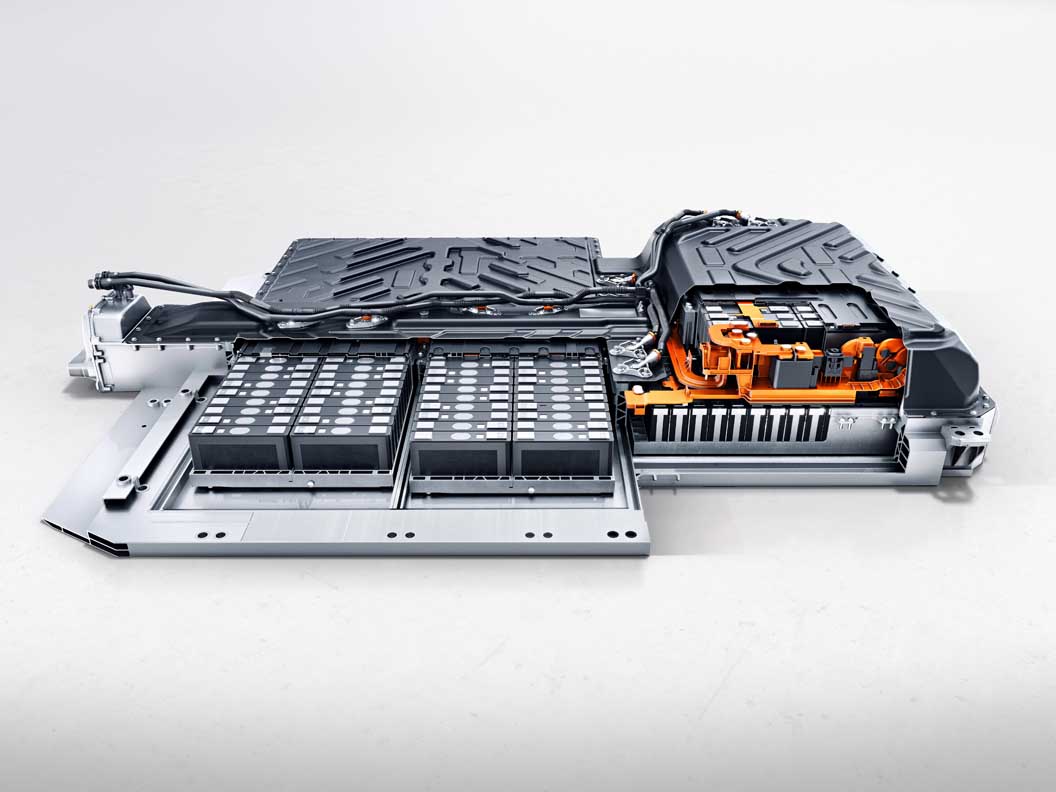

The battery: Part of the intelligent thermal management system

The EQA is fitted with a lithium-ion battery with a high energy density. The battery is made up of five modules and is located underneath the passenger compartment in the middle of the vehicle. The lowest point of the vehicle, however, is the lower edge of the side skirts, giving the EQA more than 200 mm of ground clearance.

The battery features a “double-decker” design, making it another example of the intelligent use of space: The “nose” of the battery, which accommodates the battery management system, is situated towards the front, behind the centre console. An aluminium housing as well as the body structure of the vehicle itself protect the component from potentially touching the ground and against loose chippings. The battery housing is part of the vehicle structure and thus an integral part of the crash concept (see section on “Passive safety”).

The powerful high-voltage battery has a maximum voltage of 420 V and a nominal capacity of 190 Ah, giving it an energy content of 66.5 kWh.

The battery is part of the intelligent thermal management system of the EQA. To ensure that it is always kept within the optimum temperature range, it can be cooled or heated as required via a coolant-fed plate underneath the battery.

If Navigation with Electric Intelligence is activated, the battery may also be pre-heated or cooled while driving in order to ensure that it is within the ideal temperature window for a rapid charging station. On the other hand, if the battery is cold when the car reaches the rapid charging station, a considerable proportion of the charging capacity will initially be used simply to warm it up. The net effect is to optimise the charging time – important, as a means of significantly shortening the charging stop.

As for all other high-voltage batteries, Mercedes-Benz issues a battery certificate, thus providing a performance warranty. This is valid for eight years or a distance covered of 160,000 kilometres and guarantees a properly functioning high-voltage battery: the certificate also covers capacity loss in the battery.

Charging management: CCS charging socket for alternating current as well as direct current

At home or at public charging points, the on-board charger provides a convenient way of charging the EQA with up to 11 kW using alternating current (AC). The charging time required for a full charge depends on the available infrastructure and the country-specific vehicle equipment. Charging at a Mercedes-Benz Wallbox is considerably faster than at a domestic power socket.

And it is of course even faster at direct current (DC) rapid charging stations. Depending on the SoC (state of charge) and the temperature of the high-voltage battery, the EQA can be charged with a maximum output of up to 100 kW at an appropriate charging station. The battery can be charged in this case from 10 – 80 percent SoC in around 30 minutes. For AC and DC charging, the EQA is equipped as standard in Europe and the US with a CCS connector (Combined Charging System) in the right-hand side wall. In Japan or China the corresponding country-specific charging sockets are used. The charging times may also vary compared with those for the European model.

Intelligent networking ensures energy recuperation to suit the situation

ECO Assist offers a recuperation process optimised to the particular situation. It takes into account navigation data, traffic sign recognition and information from the vehicle sensors in its efficiency strategy. Anticipatory driving saves power, thereby extending the range.

ECO Assist coaches the driver with messages when the accelerator can be released, for instance because a speed limit is approaching, and with functions such as gliding and specific control of recuperation. For this purpose, navigation data, traffic sign recognition and information from the intelligent safety assistants (radar and stereo camera) are linked and processed.

ECO Assist continuously generates coasting simulations in the background: depending on the state of charge of the battery and the traffic situation, it computes whether the vehicle should ideally be allowed to coast (or “glide”) with the lowest possible driving resistance with the driver’s foot off the pedals, or whether it should be decelerated so that the battery can be efficiently charged (recuperation).

ECO Assist takes the following traffic situations and information into account in its driving recommendations and efficiency strategy:

- Route profile (bends, junctions, roundabouts, gradients)

- Speed limits

- Distance from vehicles travelling ahead

Within the limits of the system, ECO Assist controls the overrun according to the situation as soon as the driver’s foot leaves the accelerator. The driver is also given a visual prompt to do this: by showing a “foot off the accelerator” symbol in the media display (or if available, in the head-up display). At the same time, a diagram gives the driver the reason for the recommendation (e.g. “Junction ahead” or “Gradient ahead”).

ECO Assist predictively computes the driving situation when deciding whether to drive with the lowest resistance or whether to recuperate. Examples include dips in the road, brows or speed limits ahead, which the system recognises from the map data.

- Dip: The vehicle recognises that a downhill gradient is followed by a climb, and that a speed limit is shown. The driver receives the prompt “Foot off accelerator” in good time. As soon as the driver acts on this, the vehicle continues with the drive switched off. Recuperation takes place on the downhill stretch, but only enough to ensure that the maximum permitted speed is maintained. Recuperation ends just before the lowest point in the dip, and coasting commences, in order to maintain as much impetus as possible for the uphill stretch.

- Brow: If ECO Assist recognises that “gliding” makes sense on account of the individual driving situation, the topography and the speed limits, the driver is told to “remove foot from accelerator” even before reaching the brow. The vehicle then drives over the brow in “gliding” mode, and subsequently uses the downhill stretch to reach the target speed.

- Speed limit: When the system recognises a speed limit from the navigation data or via Traffic Sign Assist, the driver is once again prompted with “Foot off accelerator pedal”. The vehicle is then gently decelerated (while recuperating) to the new speed, followed by coasting. In this way suitable speeds for junctions, roundabouts and bends are also supported.

- Slow-moving traffic: When the radar sensors of the system recognise slow-moving vehicles ahead while coasting, gliding is automatically interrupted if necessary. Deceleration with recuperation takes place to the extent that braking action by the driver is often unnecessary. If the vehicle ahead accelerates, coasting is reactivated automatically so as to cease deceleration and maintain the current speed as much as possible. The driver operates the accelerator if needed.

The EQA offers various ways to recoup energy through recuperation. In general terms the process involves recharging the high-voltage battery by converting the mechanical rotation in overrun mode or during braking into electrical energy.

The driver can select the recuperation function manually using paddles behind the steering wheel. The two paddles behind the steering wheel can be used to influence the recuperation level. The paddle on the left increases the level of recuperation, the paddle on the right reduces it. The driver can see the selected setting in the instrument cluster. The following recuperation stages are available: DAuto (recuperation via ECO Assist to suit the particular situation, see next section), D+ (coasting), D (low recuperation), D- (medium recuperation) and D- -(high recuperation). New with the EQA is that, if the function DAuto is selected, this mode remains the setting when the car is restarted. To stop, the driver must activate the brake as normal, whatever the recuperation stage.

Reduced drag extends range

The aerodynamic development of the Mercedes-BenzEQA was largely undertaken digitally. The ensuing measurements undertaken in the wind tunnel confirmed the high quality of the numerical simulation. With a Cd value from 0.28, the EQA matches the very good figure already achieved by the GLA, although the base model includes larger, 18-inch wheels. The frontal area A totals 2.47 m2.

The EQA develops the already good aerodynamic basis of the GLA further. A new aerodynamic setup was necessary due to the new bumpers and the resulting different diffuser angle. The extent to which the air flow at the front wheels breaks away has been reduced by the design of the bumper and the configuration of the wheel spoilers, designed specifically for the EQA, with their wedge-shaped profiles.

The underbody panelling is also new. As an electric vehicle the EQA has no need for a transmission tunnel, exhaust system and fuel tank, these being replaced by a smooth-surfaced battery. The air flow along the underside of the body is guided virtually unimpeded from the front apron over the engine compartment panelling and three main floor panels through to the similarly enclosed rear axle and diffuser trim. Considerable attention was also given to the details: the ribs that give strength to the underfloor panelling, for example, all run front to back.

The cooling-air intake is also to a design specifically for an electric vehicle: since the EQA has less need of cooling than a car with a combustion engine, the upper part of the cooling-air intake could be completely blanked off. The lower section features adjustable radiator shutters.

The aerodynamic measures at a glance:

- Aerodynamic design of front and rear aprons

- Wheel spoilers with wedge-shaped profile at the front, wheel spoilers at the rear

- Cooling-air control system in the lower section of the front apron, smooth panel enclosing upper air intake

- Improved sealing of radiator section to ensure efficient use of cooling air

- Sealed headlamp surrounds

- Aerodynamically and aeroacoustically optimised exterior mirrors

- Large roof spoiler, side spoilers and air flow break-away edges in the tail lights

- Optimised underbody panelling concept including large trim panels enclosing engine compartment, main floor, rear axle, diffuser and spring links

- Aerodynamically optimised wheels (many enclosed surfaces, minimal concavity, openings in the inner section) and tyres for all sizes of wheel.

Sophisticated thermal management system with heat pump as standard

With automatic climate control as standard, the EQA offers the same high level of climate comfort as every Mercedes-Benz. For this it features a sophisticated thermal management system with a heat pump as standard. With its numerous innovative details, such as the reuse of the waste heat from the electric drive system, the system is configured for exceptional efficiency and thus maximum range. Pre-entry climate control also ensures that EQA drivers have no need to scrape the windscreen in the morning, nor to get into a freezing cold vehicle. And even in hot summer temperatures, the interior is cooled to a pleasant level before starting a journey.

It is possible to set the pre-entry climate control for the interior of the EQA before starting. This function is controlled directly via MBUX or via the Mercedes me App. Making use of pre-entry climate control during the charging process helps to preserve range, since the energy requirement is supplied through the charging current and does not impinge on the range.

Pre-entry climate control uses target values as a basis. This means that when the driver inputs a departure time, the EQA is climatised to the set temperature by that time. The driver can do this either individually for each journey and every stretch of the journey, or with the help of a weekly profile. Pre-entry climate control is also activated automatically for five minutes as soon as the vehicle is unlocked using the key. When pre-entry climate control, which can run for a maximum of one hour, starts or comes to an end, the driver receives a corresponding push notification.

In ECO mode the system will also switch to an intelligent operating strategy for the ancillary consumers. This reduces the power requirement, thereby increasing the range to suit the particular situation.

Efficient thermal architecture reduces energy requirement

The EQA features a sophisticated thermal architecture that includes a heat pump as standard. The system operates very efficiently: the waste heat from the electric drive system (inverter and electric motor) can be used to heat the interior. This reduces drastically the draw on battery power for the heating system, thus increasing the range.

A heat pump – a familiar concept from domestic heating systems – transports the warmth from a low to a higher temperature level. This means that “cold thermal energy”, which occurs particularly frequently in electric vehicles, can be used to heat the interior. How the heat pump in the EQA works, at a glance:

- Efficient reheating with air recirculation: a high proportion of recirculated air means that less (fresh) air has to be heated. To reduce the tendency for the windows to mist up, the vehicle cools the recirculating air, thereby removing moisture. The heat extracted is fed back into the interior via the water-cooled condenser and the heat exchanger. In other words, the heat is recycled.

- Use of waste heat from the electric powertrain: see above.

- Use of waste heat from the high-voltage battery: if the temperature of the battery rises above a defined threshold value, the waste heat can be used to heat the interior.

Systematic isolation and extensive insulation

The issue of NVH (Noise, Vibration, Harshness) is particularly important in an electric car. In the absence of the noises normally associated with a car with a combustion engine, any vibrations or irritating noises such as tyre noise become particularly intrusive. On top of this is the high-frequency excitation of the electric motor. In order to meet the high standard of noise and vibration comfort that is such a hallmark of the brand, complex measures have been taken to isolate the electric power train from the chassis and body. Numerous damping measures enhance this effect.

One of the development goals for the EQA was to achieve a balance between noise comfort and ride comfort at a high level. A particular focus of this work was on the noise from the drive system and the integration of the electric powertrain. Components with a relevance to NVH were configured accordingly during the digital development phase, checked in the hardware phase on test rigs and only then integrated into the vehicle. The final refinements were then undertaken during road testing: in the complete vehicle it was then possible to identify transmission paths, eliminate critical resonances and reduce the noise from the drive system to an acceptable level. As when a house is built, efforts were concentrated first on the body-in-white/platform and then on the interior fit-out/insulation, since the isolation or immediate encapsulation of the electric drive unit is demonstrably more effective than damping measures in the interior. The acoustic insulation measures include an enclosed passenger compartment, efficient damping systems on the metal surfaces and acoustically effective trim elements.

Pleasantly unobtrusive noise from the powertrain thanks to isolation of front- and rear-axle drive systems

The single-speed transmission that forms an integral part of the electric powertrain at the front axle (eATS) operates particularly smoothly thanks to the improved microgeometry of the gearing. NVH measures around the electric powertrain were incorporated into the EQA at an early stage of component development. The power electronics unit, for example, was reinforced and secured firmly to the housing.

In an electrically powered vehicle, the low-frequency background noise associated with a combustion engine is missing, which means that high-frequency noises can become more apparent. For this reason, the front- and rear-axle powerpacks on the EQA have been isolated at several points. Components such as the supporting frame at the front axle, the rear-axle subframe and even the rubber bushings were developed in tandem with the digital development phase and continually optimised. These efforts ensure that no irritating noises are perceptible inside the vehicle.

Ancillary components, too, were significantly improved with respect to noise and vibration comfort. The air-conditioning compressor, for example, together with the front powerpack, was isolated from the supporting frame by means of rubber-bonded metal elements. In order to reduce structure-borne sound, the air-conditioning pipes were modified to follow the rigid elements in the bodyshell, and the bearing points isolated as far as possible. In addition, the operating strategy of the air-conditioning compressor avoids engine speeds that could have a detrimental impact on the noise level in the interior. This has no effect on climate comfort.

Low road noise thanks to targeted improvements in rigidity and an ingenious bearing concept

In order to reduce road and tyre noise, the engineers introduced a compact, shear-resistant integral mount which has significantly increased the introductory rigidity at the guide bearing of the front axle. The subframe of the multi-link rear axle is furthermore elastically isolated by rubber bushings. The front subframe connection is integrated into the C-ring structure and therefore has the necessary rigidity for isolation. A cross-member is integrated into the multifunction recess to increase the introductory rigidity of the rear subframe connection.

Low road and tyre noise is an important factor in terms of ride comfort, particularly when driving on country roads. As well as on the configuration of the bodyshell structure and the sound insulation, development work focused on the dynamic transmission characteristics of the various axle components and elastomer bearings. The redesigned front axle subframe allows the connection rigidity for the suspension strut and brake to be significantly increased. Subframe mounts are used in all instances for the rear axle. In conjunction with the reinforcements introduced at the various connection points, this reduces the intrusion of noise. The bearing concept used in the case of the multi-link axle allows greater longitudinal vibration damping, while the dynamic transmission in a vertical direction remains limited.

Alert and quick to react

The Mercedes-BenzEQA features a range of intelligent driving assistance systems with cooperative driver support. The enhanced functions of the Driving Assistance Package include, for example, the turning manoeuvre function, the emergency corridor function, the exit warning function alerting the driver to approaching cyclists or vehicles, and a warning when pedestrians are detected near zebra crossings.

Included as standard on board are Active Lane Keeping Assist and Active Brake Assist. In many situations the purpose of the latter is to prevent a collision by autonomous braking, or to mitigate its consequences. The system is also able to brake for stationary vehicles and crossing pedestrians at typical city speeds and even to prevent collisions, depending on the situation.

In certain situations the EQA is able to drive in partially automated mode. To do this, it keeps a close eye on the traffic situation. Improved camera and radar systems allow it to see far ahead. The EQA also uses map and navigation data for assistance functions. For example, Active Distance Assist DISTRONIC as part of the optional Driving Assistance Package is able to provide route-based support to the driver in numerous situations, and to predictively and conveniently adjust the speed, e.g. when approaching bends, junctions or roundabouts. In doing so, it interacts with ECO Assist. Also on board, for example, is Active Emergency Stop Assist.

The Driving Assistance Package (optional equipment varying according to country and equipment level) includes:

- Active Distance Assist DISTRONIC with the functions:

- braking for stationary vehicles,

- extended, automatic moving off in a tailback in conjunction with Active Parking Assist and navigation,

- Active Steer Assist with the functions:

- Active Emergency Stop Assist – with automatic unlocking and emergency call to the Mercedes-Benz Emergency Call Centre when the vehicle comes to a stop (depending on country),

- Emergency lane function: in motorway tailbacks at speeds below 60 km/h.

- Active Speed Limit Assist with reaction to changing speed limits in conjunction with Traffic Sign Assist, route-based speed adjustment ahead of bends, roundabouts, toll booths, T-junctions and before joining/exiting motorways, expressways – in conjunction with Live Traffic Navigation, also speed reduction when approaching the end of a tailback,

- Evasive Steering Assist,

- Active Lane Keeping Assist,

- Active Blind Spot Assist,

- Active Brake Assist with turning manoeuvre and cross-traffic function,

- PRE-SAFE® PLUS: can detect a potential rear impact. If the danger of a collision persists, the system can also firmly apply the brakes of the stationary vehicle, minimising the risk of whiplash injuries by reducing the forward jolt caused by an impact from the rear.

Even in its purely indicative version, and at low speeds, Blind Spot Assist is able to warn of vehicles, including bicycles, in the danger area. When the vehicle is stationary the system can indicate to you before you get out, via a visual warning in the outside mirror, that a vehicle is driving past within the critical area. If the driver or rear-seat passenger uses the door handle at this moment, an additional acoustic warning sounds and the ambient lighting in the door flashes red. The passing road user must be moving at a speed exceeding 7 km/h at the time. The exit warning function of Blind Spot Assist is available when the vehicle is stationary, and for up to three minutes after switching off the ignition. When on the move, Active Blind Spot Assist, which is part of the Driving Assistance Package, is also able to react to vehicles in the blind spot and in critical areas with active braking intervention.

Traffic Sign Assist: posted speed limits and any potential no-overtaking signs are displayed for the current section of the route through image recognition and information from the navigation system’s digital road map. The vehicle speed is compared with the speed limit. When the driver selects the appropriate settings, a visual/visual-acoustic warning signal is issued any time the speed limit is exceeded. No-entry restrictions are also recognised. Furthermore, the system warns of pedestrians detected in the area of pedestrian crossings.

Hallmark Mercedes feature: The EQA is comfortable and agile to drive

As standard the EQA features a comfort suspension with steel springs, and all versions have a multi-link rear suspension. The suspension with Adaptive Damping System (option) offers the driver the possibility of choosing their preferred damping characteristics, thus enhancing their comfort noticeably.

The EQA has a MacPherson front suspension. The wheels are guided by control arms below each wheel centre, the MacPherson struts and two tie rods. The wishbone is forged from aluminium. This reduces the unsprung masses. The steering knuckles are made of cast aluminium.

All EQA models have a sophisticated four-link rear suspension. The three transverse links and one trailing arm at each rear wheel are configured for maximum driving stability, ride comfort and longitudinal/lateral dynamics. The rear axle is mounted on a subframe isolated from the body shell by rubber bushings so that fewer vibrations are transferred from the suspension to the body (see section on “Noise and vibration comfort”).

Two suspension variants: optional Adaptive Damping System

The EQA comes as standard with a comfort suspension with steel springs. A suspension with Adaptive Damping System is available as an option. This enables the driver to choose the preferred damping characteristics. A valve in each of the four shock absorbers is electronically actuated to control the oil flow. The damping characteristics are changed by regulation of the oil flow. The Comfort programme comes into its own especially when travelling at low speeds, for example on a cobblestone road.

Several sensors constantly monitor the suspension status, driving situation and driving style of the driver, and adjust the damping at each wheel. They also provide information about the drive system, recuperation and braking system, steering, and the driving assistance systems. The damping is specifically stiffened during acceleration, braking or steering manoeuvres to reduce pitching and body roll, and to improve wheel loads and the ground contact of the tyres.

More traction if desired: 4MATIC all-wheel drive

The more powerful versions of the EQA will be fitted with an additional electric powertrain (eATS) at the rear axle and therefore feature all-wheel drive. The 4MATIC system uses Torque Shift: the distribution of the torque is adjusted 100 times per second as required on a continuously variable basis between the two electric units at the front and rear axles. If the driver does not call for the full output, the motor that is not needed will be completely switched off in order to reduce the base load. In a low load range therefore, the reliance will be on the rear axle with the more efficient, permanently excited synchronous motor (PSM). Higher performance requirements will be met through the additional activation of the asynchronous motor (ASM) on the front axle.

In order to ensure maximum traction and driving stability even on snow and ice, the operating strategy reacts to spinning wheels and adjusts the torque distribution accordingly. Since the two motors are controlled independently of each other, a loss of traction on one axle does not preclude torque being sent to the respective other axle – much as with a conventional central differential lock.

Gruelling test programme around the globe

During testing of the EQA it was possible, on the one hand, to build on the experience already gained with the other models by the test drivers and engineers at Mercedes-Benz. On the other hand, the electric drive system is new to this platform. Additional tests were used to validate its strengths and durability and ensure that it would meet all customer expectations.

Ever since the automobile was invented by Carl Benz and Gottlieb Daimler, Mercedes-Benz has tested its products thoroughly and at length before bringing them to market. Systematic vehicle testing is one of the most extensive measures undertaken by Mercedes-Benz during the development process in order to guarantee the highest possible vehicle quality. Before going into production, the complete vehicle must reach a maturity level that is defined in detail in advance. Then comes intensive trialling of certain components in test vehicles, e.g. in order to ensure the longevity of a drivetrain network (the combination of – depending on the design – electric drive system, differentials, drive shafts, wheels) and individual axle components.

The most important aspects of EQA testing at a glance:

- Focus of digital testing: validation of constructive feasibility (can the car, as designed and built, be volume produced?), crash performance (accident simulations for assessing passive safety), aerodynamics, vibration characteristics (NVH), weight, etc., using VR tools

- Focus of testing on the road and on dynamometers: overall vehicle (how do the previously tested components and assemblies perform when they are integrated into a vehicle?) and long-term durability

- Ratio of digital testing to real-world testing: 35%/65%

- Expert knowledge: before being released for production, the vehicle must be tested and validated by numerous experts from many different departments. Overall, several hundred specialists are involved in testing, ranging from the specialist departments, which test and approve their components and modules, through to testing/endurance testing of the complete vehicle.

- Development period: approx. four years

- Testing period for complete vehicle: at least two winters and two summers

- Countries in which the EQA was tested: Germany (in particular at the new testing facility in Immendingen), Austria, Finland, France, Sweden, Spain, Italy, Dubai, South Africa, USA, Mexico, China, Japan

The most recent cold-weather testing of the EQA took place at Arctic Falls, Sweden.

- Testing extended to the complete vehicle, with the focus on all components and drivetrains.

- Certain components were validated with respect to all cold weather issues. This involves, for example, adjusting the air conditioning system and driving when the level of friction is low, i.e. in wintery road conditions.

- There was also an emphasis on preconditioning, charging and battery management at low temperatures.

- The engineers tested the vehicles on site down to the smallest detail and analysed them in close consultation with the relevant development departments.

At the same time, several 100,000 km are covered with the vehicles in a time lapse in various endurance tests as part of an endurance test run programme that is planned in detail. In a parallel process, cars produced locally in China are tested so that they, too, achieve the high Mercedes-Benz quality standard.