Strong together: In its transformation to emissions-free mobility, Audi is relying on the synergy effects within the Volkswagen Group. During a media visit to the multi-brand factory in Zwickau, Germany, Peter Kössler, Audi Board Member for Production and Logistics, and Dr. Stefan Loth, Chairman of the Board of Volkswagen Saxony GmbH, emphasized how intensely the sister companies are benefiting from their close collaboration. Thanks also to shared platforms like the modular electric drive system (MEB), Audi will have more than 20 fully electric models on the market by 2025.

Starting in 2026, Audi will only launch new models with electric drive systems on the global market. The company will gradually phase out production of its internal combustion engines between now and 2033. In doing so, the premium manufacturer is clearly looking to electromobility and accelerating its own transformation. The main goal: to combine individual mobility and sustainability for its customers – and to increase its profitability as a company at the same time.

Synergies accelerate transition to electromobility

The Audi Q4 e-tron and Q4 Sportback e-tron play a central role in the electrification strategy. In terms of price, they offer Audi customers an attractive point of entry into electric premium mobility. The Volkswagen Group’s platform strategy makes this possible: The Audi Q4 e-tron and Q4 Sportback e-tron are being produced in the multi-brand factory in Zwickau, where the Volkswagen ID.3 and ID.4 and, more recently, the Cupra Born are also manufactured. All these models are based on the MEB, but they score points with their brand-specific strengths.

“In the future, we will rely even more intensively on synergies within the Volkwagen Group,” says Peter Kössler, Audi AG Board Member for Production and Logistics. “This close collaboration makes the transition to emissions-free premium mobility affordable for our customers and economically presentable for us. At the same time, we make sure that all our vehicles unmistakably carry the Audi DNA within them and leave the assembly line in almost proverbially premium quality.”

The next important electric model from the company with four rings, the Audi Q6 e-tron, is also based on a new group platform: the Premium Platform Electric (PPE) developed jointly by Audi and Porsche.

The Zwickau VW factory: a pioneer in the emergence into the electric age

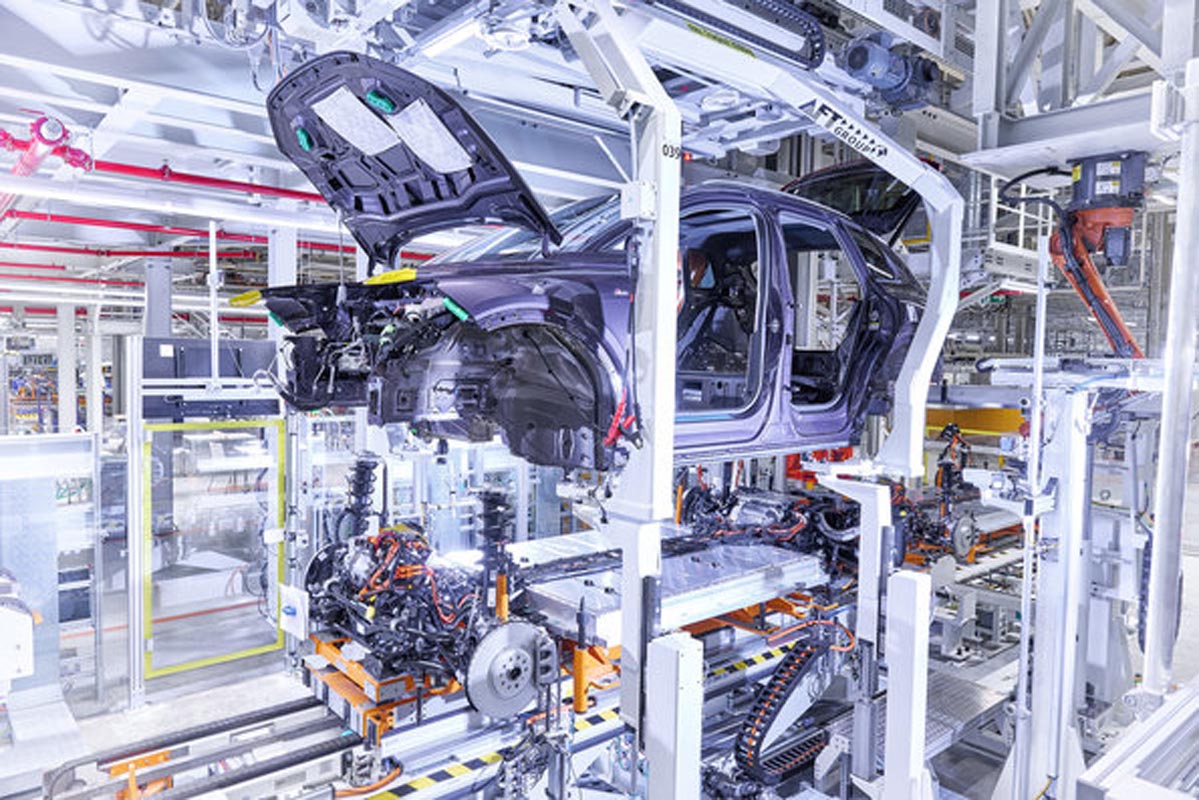

At Volkswagen Saxony in Zwickau, approximately 8,500 employees are producing the group’s five current models – all carbon-neutrally. Dr. Stefan Loth, Chairman of the Board, says, “For us, it is a special joy as well as a challenge that we have transformed from an exclusively Volkwagen factory to a multi-brand location that will soon produce six electric car models. That makes significant demands of our employees, who are responding with tremendous engagement and skill.” Many novel and innovative technologies are being used in the assembly process. For instance, the head-up display is installed directly in the assembly line. Intelligent software assesses the test image projected on the windshield and autonomously makes fine adjustments.

The Q4 e-tron: unmistakably a real Audi

Using shared platforms and technical modules has been a proven strategy in the Volkswagen Group for decades. “Teamwork across brands starts when a new platform is conceived,” says Fermin Soneira Santos, Head of Product Line for Electric Models from the A to C Segment. “It’s important to establish the right balance between distinctive brand character and maximum synergy.” For example, the Q4 e-tron is unmistakably a real Audi. This is not only apparent in the progressive design, but also in the standard Audi display and operation concept with a combination of virtual cockpit and extra large MMI, the augmented reality head-up display, which brings the interface between the virtual and real worlds together for the first time in the compact class, and in Audi’s almost proverbial claim to quality and materials in the interior.Both models successfully started in all European markets in 2021; for US customers, the compact SUVs have been available since the end of September.

Audi employees support and learn from Zwickau colleagues

The benefits of cross-brand collaboration are evident not only in the technical platforms, but also among the employees: at the moment, approximately 350 Audi employees are engaged in manufacturing in Zwickau – primarily junior staff members who have just completed their vocational training. After their one-year assignment in Zwickau, they will bring their experience in the emerging field of electromobility back to their original locations – for instance with the start of the Q6 e-tron in the Ingolstadt factory, which will be on the market starting in 2023.

Zwickau and Audi are united in a long tradition

The roots of the company with the four rings are in Saxony: when he needed to expand his operation, company founder August Horch went to Zwickau, where he registered the company “A. Horch Motorenwagenwerke AG” in 1904.

That laid the foundation for car manufacturing in Saxony. After disagreements with the board of directors, Horch left his company and founded the “August Horch Automobilwerke GmbH” in 1909, which was renamed the “Audi-Automobilwerke m.b.H.” in 1910.

Then, in 1932, the company reached another milestone in its history: the four companies Audi, DKW, Horch, and Wanderer consolidated to form the Auto Union AG; the trademark became the four rings. Stefan Trauf, Managing Director of Auto Union GmbH, the company that is changing Audi tradition today: “Zwickau was, is, and will remain a very special city for Audi. Automotive history was written here – and, then as now, it was striking just how important and productive close collaboration between brands is.” Audi history and the history of the auto industry in Saxony live on in the August Horch Museum in Zwickau (www.horch-museum.de/en/).