The Mercedes-Benz Concept CLA Class unveiled at IAA Mobility 2023 in Munich, Germany, offers a close-to-production insight into the upcoming family of vehicles that stands at the gateway to the brand. At the cusp of a new electric and digital age, this represents the company’s vision to elevate this important vehicle class, based on the long-term portfolio strategy. Designed on the forthcoming Mercedes-Benz Modular Architecture (MMA) platform, the exterior aesthetics of the Concept CLA Class stand for iconic design and dynamic performance. Meanwhile, its interior focuses on the customer experience with exceptional comfort and convenience for an electric and digital future.

“The Concept CLA Class is the forerunner for an entirely new all-electric segment of entry-level vehicles at Mercedes-Benz. The range will comprise a total of four new models – a four-door coupé, a shooting brake and two stunning SUVs – each with significantly elevated product substance. This new model family is inspired by a generation of car buyers who want that unmistakable Mercedes-Benz feel, with more features, even greater comfort and safety and the most advanced technology. They also seek a sustainable choice that is a cut above the rest. This hypermiler is the one-litre car of the electric age, with a range of more than 750 kilometres (466 miles) in the WLTP and energy consumption of just 12 kWh/100 km. Based on the MMA platform, it provides an insight into the first complete family of Mercedes-Benz electric cars developed from scratch to put our Ambition 2039 on the road, whereby we aim to achieve net carbon neutrality along the entire value chain in our fleet of new vehicles in 2039.” Ola Källenius, Chairman of the Board of Management of Mercedes-Benz Group AG.

Technology leadership is apparent in the MMA platform underpinnings such as the next-generation electric-drive system aiming for a range of more than 750 kilometres (466 miles) (WLTP). The Mercedes-Benz Modular Architecture (MMA) is an electric-first platform engineered for a family of four vehicles covering a range of body styles. It is set to play a major role in accelerating the ramp-up of the Mercedes-Benz electric fleet. As a fundamental part of the wider electric strategy, it will help the company attain its ambitious targets. All vehicles on the MMA platform are being developed in accordance with the Mercedes-Benz “real life safety” philosophy. Mercedes-Benz has set safety standards for decades, pursuing a vision of accident-free driving.

Meanwhile, the new operating system “MB.OS” is the basis for an unparalleled user interface and user experience (UI/UX) via the MBUX Superscreen derived from the innovative display in the VISION EQXX incorporating advanced real-time graphics. The Concept CLA Class showcases the use of sustainable materials throughout its structure and interior. This ranges from almost CO2-free steel and CO2-reduced aluminium to sustainably produced and processed leather upholstery as well as trim made from paper. Overall, the show car represents the approachable interpretation of desire for a youthful and dynamic global market segment.

“The technology that provides the foundation for the Concept CLA Class represents an entirely new approach for Mercedes-Benz and incorporates many learnings from our groundbreaking VISION EQXX technology programme. For instance, our engineers have maximised efficiency by driving down losses in its 800 V electric-drive system. It also features innovative battery cell chemistry as well as a high level of integration enabling excellent energy density. I am certain that our MMA platform will enable us to offer our customers in this market segment a class-defining combination of performance, sustainability, safety and comfort paired with an outstanding digital experience.” Markus Schäfer, Member of the Board of Management of Mercedes-Benz Group AG, Chief Technology Officer

MMA electric-drive system – engineered for electric efficiency

As the first car to be developed on the all-new electric-first Mercedes-Benz MMA platform, the Concept CLA Class points the way for the next-generation electric-drive technology underpinning the series-production model. With an anticipated range of more than 750 kilometres (466 miles) (WLTP), the electric drive leads by a considerable margin, defining the benchmark in its class. This represents a remarkable energy consumption of around 12 kWh/100 kilometres (5.2 mi/kWh), making the Concept CLA Class the one-litre car for the electric age. Directly derived from the electric-drive system in the VISION EQXX, the new in-house developed drivetrain comprises an 800 V electric architecture combined with a battery with exceptional energy density and a highly efficient electric drive unit. In the Concept CLA Class it is configured for sporty rear-wheel drive. However, the modular design means it is also suitable for 4×4 vehicle applications. Making its debut in the Concept CLA Class, the advanced next-generation drivetrain is scalable to fit other use cases, including in other vehicle segments.

High-voltage battery

The innovative battery system under development for the MMA platform is based on a highly modular architecture whereby customers can choose from two different cell chemistries. The top-level variant features an anode design with silicon-oxide content for excellent energy density. Meanwhile, the entry variant leads the way in the segment with its use of lithium-iron phosphate. The battery itself has a remarkably small overall volume. In a first, its cell modules are held in place using adhesive rather than screws. The resulting structure is not only lighter than a conventional battery configuration; it is also stiffer, which offers benefits in crash safety. Likewise, the 800 V configuration facilitates a high level of electric endurance in a compact package and with lower cooling requirements. The high-voltage configuration also enables high-power 250 kW DC charging, delivering up to 400 kilometres (248 miles) of range in 15 minutes.

Mercedes-Benz Electric Drive Unit (MB.EDU)

Lightweight, powerful and compact: The new highly efficient MB.EDU, comprising motor, transmission and power electronics, was developed entirely in-house. Based on a modular concept, this class-defining unit is the first in a family of drive units engineered to meet a wide range of performance demands across a number of model lines. The 175 kW permanently excited synchronous machine is paired with a two-speed transmission. The high-performance power electronics incorporate control of motor and transmission in a single processor and feature a silicon carbide inverter for exceptionally efficient power usage. This reflects the high degree of functional integration throughout the MB.EDU that results in a compact overall package weighing less than 110 kilograms. Its extremely high energy efficiency of up to 93 percent from battery to wheel in long distance driving is thanks to meticulous minimisation of losses throughout the system and places it at the forefront of the sector.

Sustainability advances in the MMA electric-drive system

The permanent magnet synchronous motor in the Mercedes-Benz Electric Drive Unit (MB.EDU) features a significantly lower share of heavy rare earths than previous generations – close to 0 percent. When it comes to batteries, the new MMA electric-drive system takes a major step forward in net carbon-neutral manufacturing. Not only is cell production net carbon neutral but also cathode production. This will allow the company to reduce the carbon footprint of the cells by 40 percent. Further emissions reductions will be achieved through using renewable energy in the production and refinement of raw materials.

Bidirectional charging

Transforming vehicle into household energy storage device: The Concept CLA Class also offers a glimpse into the future of networking between electric vehicles and the energy grid. Software- and hardware-based bidirectional charging shows how class-defining technology leadership opens up new potential for customers and energy providers alike. When connected to a compatible bidirectional DC charging station, the vehicle becomes an energy storage device that could, for instance, store solar power for use later. Most importantly, it can also serve as an electricity supply, either Vehicle-to-Home (V2H) or Vehicle-to-Grid (V2G). The use of bidirectional charging may be subject to market-specific conditions in respect of legislation and the requirements of energy suppliers.

One example of V2H is the provision of back-up supply in the event of a power outage, while V2G applications include helping to balance peaks and troughs on the power grid or even the trading of green electricity on the open market. In all situations, the intelligent bidirectional charging system ensures the vehicle has sufficient charge to meet customer needs at specified departure times. Through the option of bidirectional charging at home, Mercedes-Benz is fulfilling the desire of many customers to combine their own individual mobility with a more sustainable way of living.

Design – iconic elements seen in a new light

The Concept CLA Class marks the start of a new era and the next step in the continuous evolution of the brand’s unique design language of sensual purity. The vehicle has a distinctively dynamic appearance, incorporating design elements that have become icons in their own right – reimagined for the electric and digital age. The exciting contrast of intelligence and emotion pairs with the “x-factor” of unexpected and extraordinary details to create a new interpretation of desire.

The striking use of light in its exterior design represents the Mercedes-Benz aim to be the brightest star in the constellation. It expresses the combination of electrification and digitalisation that unlocks a new elevated customer experience from the very first glance. Very-low-energy LED lighting, visible from all perspectives, is an integral part of the overall sculpture that enhances the proportions and brings added movement, life and functionality to the exterior. The long wheelbase, short overhangs, slender greenhouse and elongated bonnet convey the brand’s design ethos in this new family of Mercedes-Benz vehicles.

Mercedes-Benz designers applied the iconic three-pointed star as an emotional lighting motif throughout, re-affirming this symbol as the most enduring mark of automotive progress. This starts at the front end with the distinctive new face and continues along the flanks, with light strips above the front and rear wheel arches. Even the expansive glass roof marks a step up to a whole new level. Its illuminated and animated star pattern brings an added air of sophistication to the exterior sculpture, while evoking a spa-like elegance in the interior. Meanwhile, the distinctive Mercedes-Benz laurel wreath has been reinterpreted to create a striking new pattern for the interior upholstery.

“The Concept CLA Class marks the start of a new era. It reinterprets iconic elements of the brand’s rich design heritage to craft a whole new face of Mercedes-Benz. Here, the sporty forward lean of the distinctive shark nose from the 50s and 60s pairs with a new signature graphic for the electric age. The composition enhances the so-called eyebrow of the daytime running light with a stylised star. The star motif repeats as animated light bands in the A-shape grille design. These are defining features of our future look.” Gorden Wagener, Chief Design Officer, Mercedes-Benz Group AG

Exterior design in detail

Emotionally charged expression of athletic power: The dynamic front end of the Concept CLA Class is characterised by the shark-nose design and the distinctive seamless “grille” panel. It forms a cohesive part of the overall sculpture and becomes a canvas for the illuminated animated star pattern as well as the central, iconic Mercedes-Benz star, likewise illuminated. The light bands that wrap around the front and rear add three-dimensionality to the light composition as well as anchoring the striking star-shaped headlamp clusters. These bands are made from an innovative material that has a stylish mirrored chrome look when unilluminated.

A range of animated lighting scenarios by day and night deliver an even greater sense of emotion and dynamism. They also offer an added dimension of personalisation for the driver, such as welcome and goodbye scenarios. The sporty proportions of the Concept CLA Class are emphasised by its athletic shoulders extending from the front light band all the way to the powerful GT rear end. The sense of breadth front and rear is underscored by the flared wheel arches and wide track, which give the show car a confident and assertive stance.

The sleek glasshouse features chrome applications that complement the athletic proportions with timeless elegance. As befits the coupé design language, the visual centre of gravity sits low down. The powerful wheel arches frame the striking 21-inch wheels displaying a distinctive star pattern. Precise joints and shutlines add detail and movement to the effortlessly sculptural surface design of the Concept CLA Class.

The crisp GT line and proportions of the rear-end serve to elongate the silhouette, while offering rear-seat passengers increased headroom relative to the previous generation. Likewise, the longer wheelbase affords more kneeroom for those riding in the rear. Viewed from the rear three-quarters and the rear, the design continues the theme of light and shade transported into the digital age. The wrap-around light band frames the rear light clusters that repeat the signature star design. The Mercedes-Benz star on the rear is likewise illuminated, creating a distinctive sign-off for anyone following behind.

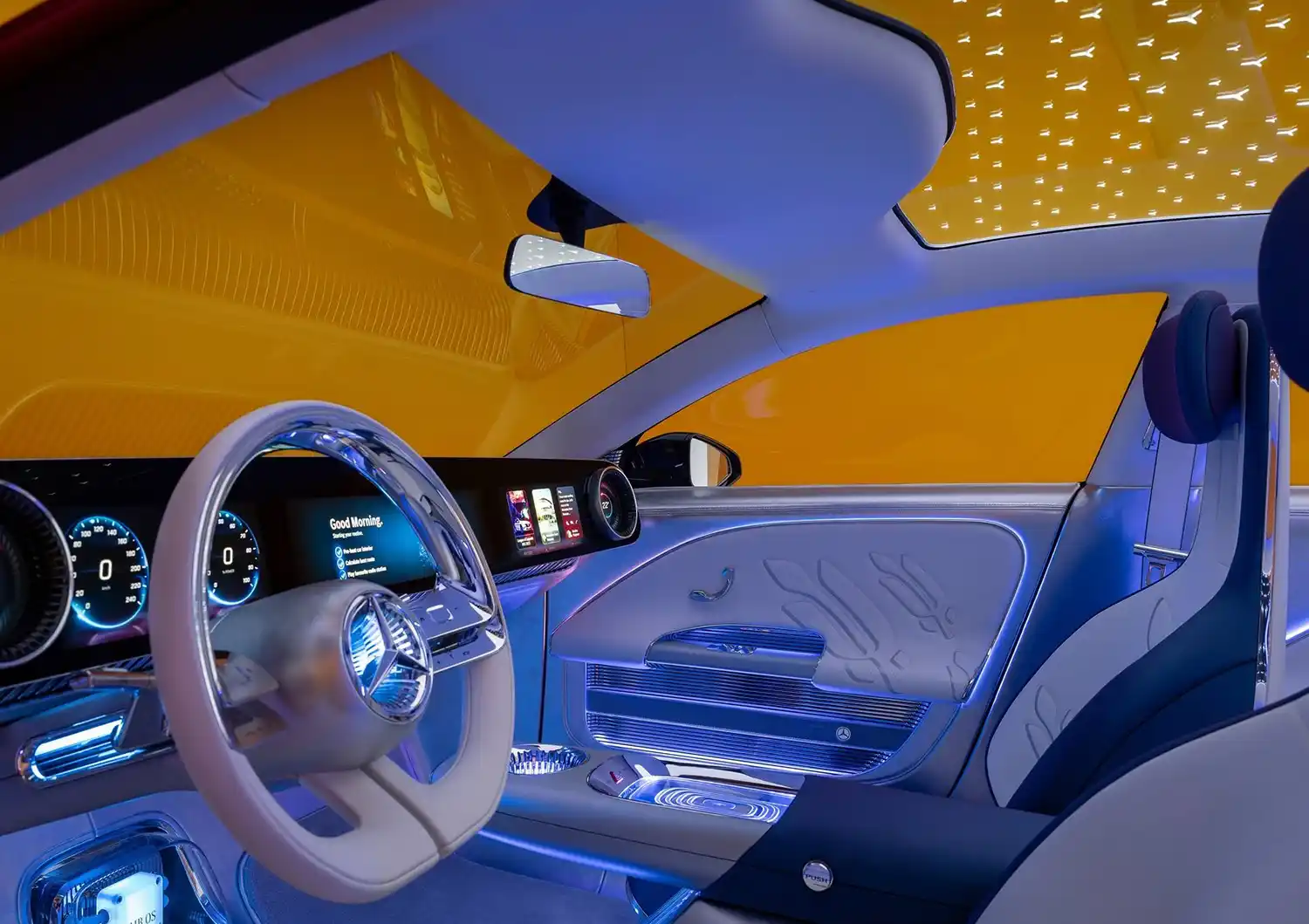

Interior design in detail

Blend of analogue and digital brings fresh definition to the segment: Inside the spacious and airy interior of the Concept CLA Class, the aesthetic theme is one of utmost modernity. This is simply yet powerfully expressed through the considered application of a few iconic elements. The overall effect exudes a tech-infused minimalist elegance that takes sculptural automotive design into an exciting digital future and sets the tone in this segment. Finely crafted innovative materials such as paper trim and nappa leather processed using vegetable-based tanning agents contrast with high-gloss surfaces to offer a visual and tactile finish that is both stylish and unexpected. By day, it is bathed in natural light from the expansive glass roof and accented by carefully orchestrated, discreet LED lighting. The colour palette of gleaming silver and crystal white enhances the futuristic atmosphere, while detailing in cool blue and sensual violet adds a hint of exclusivity.

User interface

Inspired by the very latest consumer electronic devices: Mercedes-Benz sets a very clear benchmark in the segment with the user interface in the Concept CLA Class. Dominating the full width of the cockpit is the slender continuous sweep of the MBUX Superscreen, featuring the high-efficiency mini-LED technology and immersive 3D graphics pioneered in the VISION EQXX. Its proportions emphasise the width of the interior, while adding to the sense of lightness by appearing to float in front of the driver and front-seat passenger. Furthermore, with its razor-sharp high-definition graphics paired with class-leading digital features, the MBUX Superscreen becomes a dynamic and individualised feature of the interior design.

Meanwhile, the unibody aluminium housing reflects the design of a state-of-the-art high-end device. Digitally visualised on the far left and right of the screen are iconic turbine-like virtual air vents. This unique and eye-catching fusion of analogue and digital represents the next evolutionary step, known as hyper-analogue. The familiar iconic form has been reinterpreted as a climate-control interface. Displayed on the fixed inner ring is the cabin temperature setting. The outer analogue ring emerges smoothly from the glass surface to serve as the control. The precision-machined ring can be turned to adjust the settings thus creating a seamless transition from the digital to analogue user experience. The physical air vents are positioned discreetly behind the screen and designed to convey the impression of cooling ribs – an ingenious configuration that doubles as a source of ambient lighting. This design motif in combination with illumination is a recurring theme throughout the interior.

From paper to processors

A sense of space, freedom and intelligence enhanced by surprising details: The front bucket seats take the iconic form of purist mono-swing shells derived from a spherical whole, endowing them with an enveloping sense of safety and protection. Each sculptural outer shell gives way to a soft enveloping interior, carefully designed in layers that combine the seat cushion, backrest and side cushions in a unified whole. The lateral supports emerge from the base layer in smooth, three-dimensional S-curves. Inspired by winglets, they create an extremely pure yet sculptural form. Providing a more opulent contrast, the -adjustable headrests are seemingly suspended in a cut-out. This serves to open up the design, while at the same time maintaining the seats’ integrated look. The seats are upholstered in sustainably produced and processed nappa leather that contrasts shimmering silver with crystal white embossed with a modern reinterpretation of the iconic Mercedes-Benz laurel-wreath pattern. The colour combination further emphasises the apparent weightlessness of the overall design.

Appearing to float between the driver and front-seat passenger in front of the cantilevered armrest, the high positioning of the centre console emphasises the minimalist sporty elegance of the interior. Its proportions and dynamic orientation towards the MBUX Superscreen create a fresh sense of space and openness. In a first for Mercedes-Benz, the visually striking trim element incorporates an illuminated transparent surface for inductive charging of a smartphone as well as a cupholder featuring the illuminated cooling-rib motif. This aesthetic quality dispenses with the need for a cover. The same design theme is also visible beneath the console in a sweeping, illuminated aluminium curve that draws the eye towards a glass showcase offering a glimpse into the digital brain of the Concept CLA Class, the new Mercedes-Benz Operating System (MB.OS). The bands of ambient light are metaphors for nerves carrying signals to the water-cooled processor, which, in turn, represents the vehicle’s class-defining intelligence. The overall composition interprets the flow of data that forms part of the bond between car and occupants.

Either side of driver and front-seat passenger, the doors present a further highlight of the interior design. The subtle concave form of the underlying structure sets the stage for the brand-new iconic design of the centre panels. Seemingly suspended in front of the door body, their long proportions provide yet another sporty and dynamic visual cue. Like elegant sails, their surface flows smoothly around the geometric profile of the door handle, fusing with it to form a natural armrest. The centre door panels are finished in the same crystal-white nappa leather as the seat cushions, further enhancing their lightweight look-and-feel, and feature the Mercedes-signature laurel-wreath pattern. This defining Mercedes-Benz element, endowed with exquisite hand-finished craftsmanship, forms a strong visual bond between the brand’s unique heritage and the tech-luxury of the future. At the base of the door, the discreet pocket is edged in a high-strength, biotechnology-based and certified-vegan silk-like fabric.

Technology transfer from VISION EQXX to Concept CLA Class

In implementing the vision for the future of Mercedes-Benz in this segment, engineers continue to draw on many valuable findings from the original Mercedes-Benz electric hypermiler, the VISION EQXX, which continues to set the technology benchmark for this class of vehicle. In addition to the mini-LED MBUX Superscreen with thousands of local dimming zones, these range from electric-drive and thermal efficiency measures to lightweight design through bionic optimisation to the application of sustainable materials.

The VISION EQXX technology programme was conceived to push boundaries and exercise immediate influence on series development. Hence, the next-generation electric drive unit (comprising the electric motor, transmission and power electronics) is directly derived from the highly efficient unit in the VISION EQXX and features a new generation of silicon carbides in the power electronics. Likewise, the high-voltage battery uses the same principles of functional integration and cell packaging to achieve an exceptionally high energy density. Another innovation transfer is the further developed heat pump, which already impressively demonstrated its effectiveness in the VISION EQXX programme. In a marked improvement over existing automotive heat pumps on the market, it extracts heat not only from the drivetrain but also from the ambient outside air – even at sub-zero temperatures – to heat the cabin of the Concept CLA Class. Together with an intelligent operating strategy, the heat pump can contribute significantly to electric range during cold winter weather by minimising the use of additional heating.

Bionic engineering was a substantive feature of the VISION EQXX development programme. The Mercedes-Benz BioniCast name applies to structural castings engineered according to the principles of nature. This pioneering digital approach has already garnered Mercedes-Benz prestigious industry awards as the company rolls out its implementation in series production. A number of components in the MMA platform have been optimised using these techniques. Specific examples include the rear-axle console, battery console and suspension components.

The use of digital engineering techniques was a key element in the speed and efficiency of the VISION EQXX development programme. The Mercedes-Benz World of Digital Twins is a far-reaching strategy to transition to a “physical follows digital” approach across all aspects of development and beyond. The Concept CLA Class and MMA platform are engineered in accordance with that strategy. This helped to facilitate the radical “inside-out development” applied to the Concept CLA Class. Virtual simulation techniques allowed designers and engineers to focus even more on the customer perspective in a feedback loop of continuous improvement.

MB.OS – the digital foundation for Mercedes-Benz

The vision for the Mercedes-Benz of tomorrow redefines the car itself, elevating it beyond its role as a mode of transportation, assistant or companion. It becomes an entertainment and gaming centre, a productivity zone, a private oasis, even part of a server farm and the energy grid – an integral part of life. To achieve this vision by leveraging the full potential of current and future software-driven innovation, Mercedes-Benz is developing its own operating system MB.OS. This proprietary chip-to-cloud architecture represents a completely new approach for the company and will be a largely hidden yet defining aspect of all its future vehicles. The core of MB.OS is to decouple hardware and software and to make software development faster and more adaptable. This facilitates the constant follow of innovation into vehicles, resulting in a better product for customers. A proprietary system developed in-house in close collaboration with strong partners provides the company with the freedom and flexibility to innovate as well as the ability to act fast and efficiently.

The forthcoming MMA platform will be the first to run fully on MB.OS. The Concept CLA Class offers a taste of what this will mean for customers. To stress the central role played by MB.OS in shaping the customer experience, the interior of the show car offers a striking visualisation of it. The complex multi-faceted architecture is represented here by one of its many hardware components, the high-performance water-cooled chip from collaboration partner NVIDIA. This powerful partnership will help equip every vehicle built on the MMA platform with a supercomputer. MB.OS uses artificial intelligence and machine learning powered by the latest-generation chips and system-on-chips (SoCs) and is supported by highly advanced sensors and the Mercedes-Benz Intelligent Cloud.

Advanced MBUX Superscreen delivers new level of personalisation leveraged with real-time graphics

MB.OS elevates the family of vehicles at the gateway to the Mercedes-Benz brand through software and artificial intelligence (AI): One example is a unique UI/UX tailored not only to the car but also the customer’s individual preferences. It pairs the advanced three-display MBUX Superscreen in the Concept CLA Class with ambient light and sound to provide an immersive luxury experience for driver and passenger previously unheard of in this class of vehicle. Ambient styles with a range of themes for all three screens offer a further level of customisation, while the virtual assistant is on hand to support users with information and suggestions.

The MBUX Superscreen comes to life with advanced real-time graphics powered by game engine technology, as in the VISION EQXX. The instrument cluster adapts to user needs, including the level of driver assistance. In so doing, the intelligent system communicates with more than just data, incorporating shapes and light into an intuitive dialogue. This ensures the driver has a clear overview of all relevant information without overload. From the dynamic virtual cockpit that helps optimise driving style for maximum range to the 3D navigation with integrated information on points of interest, they have everything they need when they need it.

Users can also create their own personal space with beautifully depicted immersive worlds. Extensive adaptation options through dynamic digital skinning enable them to individualise their experience and self-expression in an instant. Crystal-clear resolution and vibrant colour rendering result in an overall effect that takes the MBUX Superscreen beyond in-car display to create a multi-media experience. Entertainment is provided courtesy of extensive integration of top-quality third-party apps. Beyond this, the MBUX Collectibles feature enables the creation of a private art gallery by connecting the customer’s personal NFT wallet and enabling them to browse an exhibition curated by Mercedes-Benz. MB.OS also brings class-leading passenger entertainment into this new vehicle family with a range of third-party video streaming options available only to the passenger while the car is traveling. Numerous layers of safety, including eye-tracking technology, ensure the driver is not distracted.

Concept CLA Class with enhanced SAE Level 2 performance thanks to LiDAR

As with all technical innovations, the company measures those in the Concept CLA Class by the contribution they make to the Mercedes-Benz vision of accident-free driving. The extensive driver assistance and safety systems under development for the MMA platform make it possible, for example, to drive partially automated (SAE Level 2) on virtually all types of roads, to aid the driver when changing lanes on multi-lane roads, to automatically manoeuvre into and out of tight parking spaces, and to prevent or reduce the severity of collisions in an increasing number of situations.

Automated driving systems in vehicles based on the MMA platform will offer best-in-class driver assistance. The MMA platform heralds an extensive sensor set that maintains Mercedes-Benz’s leading position in this field. In addition to multiple cameras facilitating surround, wide and tele views, the base set also includes a full range of radar and ultrasonic sensors.

Future SAE Level 2 applications are also prepared for the use of LiDAR-supplemented sensing technology to meet the high operational complexities and safety demands of urban traffic. In this segment, these powerful sensors will enable customers to equip their vehicle with a wide range of SAE Level 2 features. It will be possible to enhance these via over-the-air updates, even after vehicle purchase. This also means that Mercedes-Benz will be able to continually improve existing systems and make them available to customers (taking account of local legislative frameworks), thereby ensuring their cars remain at the very forefront of innovation in the segment. The MB.OS software and its computing power is generally ready for an SAE Level 3 system upgrade for vehicles equipped with a comprehensive sensor set including a LiDAR sensor and redundancies for vital vehicle systems.

Advanced Child Presence Detection system

A further benefit of the MB.OS architecture: The ability to facilitate an extremely high degree of networking of vehicle systems, sensors and actuators makes it easier for Mercedes-Benz to develop and implement highly sophisticated safety functions. One example is the new Child Presence Detection (CPD) system. It is designed to mitigate the risk of young children being accidentally left in a car during warm weather – and the associated, sometimes tragic, consequences.

Based on a network of more than 20 system interfaces, the future system is activated when it detects the presence of a child in the vehicle through their distinctive breathing pattern. The sensors involved are so sensitive, they can even detect the gentle breathing of a sleeping newborn baby. Meanwhile, cameras can detect the presence of an adult e.g. in the passenger seat. When the system determines a child is in a parked car, it alerts the driver as soon as the motor is switched off. Should the driver leave and lock the vehicle, this triggers an escalation process. If the vehicle and the smartphone are connected with the same Mercedes me account, the system sends messages to the smartphone at frequent intervals.

Meanwhile, the system also monitors the car’s interior temperature. Should it exceed a critical point, a process of measures kicks in: the car’s exterior lights flash accompanied by an acoustic signal. Designed to attract bystanders towards the vehicle, the signal differs from the shrill claxon of a typical car alarm. At the same time, the car’s air conditioning kicks in to reduce the cabin temperature to a less critical level. Warning messages are also sent at this point to all smartphones registered to the vehicle and connected with the same Mercedes me account. The final escalation stage is to notify the Mercedes-Benz SOS call centre and/or alert the emergency services.

With safety the top priority, the focus is on the prevention of tragic accidents, with the system specifically configured to avoid intentional use for stationary air conditioning.

MB.OS – the road ahead

The digital possibilities presented by MB.OS are considerable and far-reaching: For vehicles based on the MMA platform, they promise a level of individualisation, seamless interaction and infotainment previously unheard-of in this segment. It will help the brand with the three-pointed star elevate the digital experience with an even more intense focus on the customer. The Concept CLA Class offers a glimpse of that, with more to come in the near future.

Putting Ambition 2039 on the road – sustainability and circularity

Mercedes-Benz is fully committed to its Ambition 2039, which aims to achieve net carbon neutrality along the entire value chain in its fleet of new vehicles in 2039. This not only applies to the supply chain but also informs the company’s strategy and mindset that the future of mobility must be sustainable. As well as being all-electric, this approach is also underpinned by the circular economy. All of this is viewed through the lens of Mercedes-Benz’s aim to build the world’s most desirable cars. The MMA platform underpins the first family of vehicles designed from the very start to the principles set out in Ambition 2039. It reduces value-chain CO2 by more than 40 percent over the entire MMA fleet compared to the previous architecture. The Concept CLA Class represents the firstborn of this new family.

Innovative interior trim

More than looking good on paper: When creating the interior of the Concept CLA Class, Mercedes-Benz designers had the clear aim of leading by example when they placed sustainability and circularity at the top of the list of priorities. These crucial topics took equal billing alongside first-class visual and tactile qualities, resistance to wear and tear and safety criteria. Appearing for the first time in a Mercedes-Benz is an innovative paper material made from recycled cellulose – with a 50/50 composition of recycled cellulose and hemp targeted for series-production. As a trim element, it provides a strikingly progressive look & feel with great design flexibility. It is produced using renewable energies and innovative sustainable technologies such as ozone water purification and generates zero landfill waste.

The seats themselves are upholstered in sustainably produced and processed leather. This takes into account everything from livestock breeding to the tanning process. In addition to compliance with the Animal Welfare Committee’s “5 Freedoms of Animal Welfare”, requirements also stipulate that the leather supply chain must be free from any form of illegal deforestation and that grazing areas must not contribute to the endangerment or loss of natural forests. The leather itself is tanned using vegetable-based tanning agents such as coffee bean husks, chestnuts or extracts from other renewable raw materials. Furthermore, the leather may only be processed in tanneries that are certified according to the Gold Standard of the ‘Leather Working Group’. This includes important environmental aspects such as reducing the use of water, energy, and chemicals in the tanning process.

The floor mats in the Concept CLA Class are woven from bamboo fibre, while the door pockets are edged in a biotechnology-based and certified vegan, high-strength, hardwearing silk-like fabric. Both materials were first showcased in the VISION EQXX. They are not only highly functional but also extremely attractive with luxurious tactile qualities. Meanwhile, the polyester textile upholstery on the floating centre armrest is made from recycled PET.

Beneath the skin of the Concept CLA Class

Cutting the carbon footprint of steel and aluminium: Beneath the beautiful exterior of the Concept CLA Class lies a consistent push to decarbonise the supply chain for the next generation of cars in this segment. The advances made in the electric-drive system to improve the sustainability of the battery and the electric drive unit (see above) represent just one aspect of a comprehensive and multi-faceted approach.

With steel and aluminium among the major contributors to the carbon footprint of the vehicle production process, Mercedes-Benz has set clear emissions-reduction targets through decarbonisation of focus materials, increased recycled content and the use of renewable energies. This, too, is an important part of the meaning behind “defining class”. During the development process for almost CO2-free steel and CO2-reduced aluminium, the materials and resulting components are carefully examined and extensively tested to ensure they meet stringent Mercedes-Benz crash safety standards.

In Europe, the company is striving to significantly reduce the carbon footprint of the steel in 50 percent of in-house pressed parts used in its entry vehicles. This would lead to a saving of around 100 kilograms of CO2 per vehicle. In addition to recycled steel produced in electric-arc furnaces powered by renewable energy, the material mix will include steel derived from direct reduction using green hydrogen, phasing in over vehicle lifecycle depending on availability.

The MMA platform also accelerates the strong progress Mercedes-Benz is making in the use of CO2-reduced aluminium. In Europe, at least one third of the aluminium in the upcoming electric model generation will be produced with renewable energy. Applications cover a wide range of components from the wheels to the battery housing. This will lower the CO2 footprint of this aluminium by a minimum 40 percent compared to aluminium used in Europe, equating to a reduction of around 300 kilograms of CO2 emissions per vehicle. On the path towards a fully responsible aluminium supply chain, the company will significantly increase the share in future models of aluminium certified according to the standards of the Aluminium Stewardship Initiative (ASI). Currently, the aluminium sheet for in-house press parts is sourced from ASI-certified suppliers.