The 2022 GMC HUMMER EV Edition 1 will be the first vehicle in production with GM’s all-new Ultium battery architecture and will offer impressive on- and off-road features and a broad range of vehicle dynamics and performance features.

This new architecture provides the framework to integrate advanced technologies for optimal driving range and — in the case of the HUMMER EV — will enable performance and capabilities that would not be possible with a conventional vehicle architecture and propulsion system.

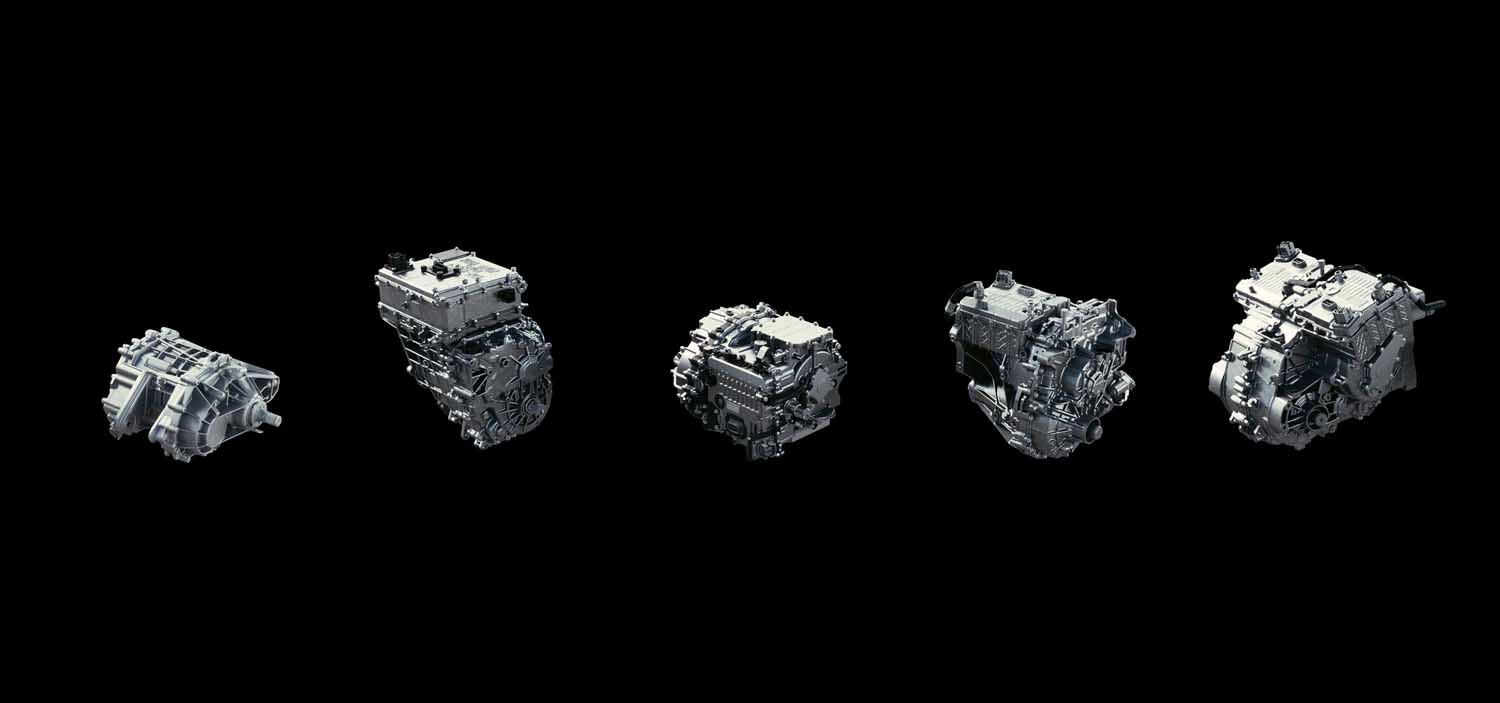

The 24-module Ultium battery pack and three-motor Ultium Drive system will provide this all-electric supertruck best-in-class power output.

“As the first of GM’s next-gen EVs, the HUMMER EV will fundamentally alter conventional off-road and truck paradigms,” said Ken Morris, GM vice president, Autonomous and Electric Vehicle Programs. “It will also debut new technology, including our all-new Ultium batteries, Ultium Drive units and the industry’s first wireless battery management system.”

Ultium cells

Ultium batteries are unique in the industry because of their large-format, pouch-style cells, which can be stacked vertically or horizontally inside the battery pack. In the Edition 1 HUMMER EV, two layers of vertical cell modules will be used to produce a combined 24-module pack offering a GM-estimated range of 350+ miles6 (563 KM)

In addition to power and range, the Ultium battery pack will contribute to the HUMMER EV’s driving dynamics and structure. The pack’s low mounting position in the chassis contributes to a low center of gravity, enhancing the vehicle’s overall feeling of control and stability. The compact construction of the Ultium battery pack also contributes to HUMMER EV’s ideal off-road proportions, including a short front overhang and short front breakover angle.

With GM’s state-of-the-art nickel, cobalt, manganese, aluminum (NCMA) chemistry, HUMMER EV’s Ultium batteries will have some of the highest nickel and lowest cobalt — a rare and costly material — content of any large-format pouch cell. The breakthroughs of the Ultium chemistry allow GM to use 70 percent less cobalt than GM’s previous generation of EVs.

HUMMER EV will also be the first vehicle in GM’s lineup to feature its wireless battery management system, which maintains balance within the truck’s battery cell groups for optimal performance and battery longevity.

Electrifying off-road

“This is the first truck that we have ever designed around an EV propulsion system,” said Adam Kwiatkowski, GM executive chief engineer, Global Electric Propulsion. “Designing the truck and the propulsion system together enhances HUMMER EV’s unique performance capabilities, while also making this the stiffest truck GM has ever built.”

Edition 1’s three electric drive motors within Ultium Drive will yield a combined GM-estimated 1,000 horsepower, and when multiplied through the front and rear drive unit gear ratios, there will be more than a GM-estimated 11,500 lb-ft of torque available at the wheels.

The single-motor front drive unit will have a 13.3:1 fixed gear ratio and will offer an electronic lockable differential, capable of delivering up to 100 percent of the motor torque to one wheel, in case traction is lost on the opposite wheel. All four wheels can be fully synchronized for true e4WD propulsion.

Two rear motors contained in one Ultium Drive unit will independently power the rear wheels through a fixed gear ratio of 10.5:1, with the capability of varying torque output to each wheel to optimize traction in off-road driving and highway-driving conditions. Motor output can also be synchronized to simulate a locking differential.

The system’s pure electric propulsion holds peak torque much longer, through a wider speed range (up to 40 mph / 64 kmh) than even diesel engines, which is optimal for off-roading, but also thrilling on-road. For straight-line performance, the Ultium batteries and Ultium Drive will offer enough power to enable the Watts to Freedom performance feature, launching the HUMMER EV from 0-60 mph / 97 kmh in approximately 3 seconds (based on GM estimates).

DC fast charging

HUMMER EV will have the ability to take advantage of the industry’s fastest 350-kilowatt DC fast chargers4. This vehicle will offer a GM-estimated 350+ miles6/ 563 KM of range based on preliminary testing, with a unique ability to switch its battery pack from its native 400-volts to 800-volts for charging. A disconnect unit and mechanization within the pack enables the battery to switch from “parallel” to “series,” allowing it to add nearly 100 miles of range in 10 minutes of charging7.

The charging system is also designed to support legacy 400-volt charging infrastructure, without the need for a converter box or other accessories, allowing HUMMER EV to use a variety of charging stations.

Regen on Demand5, One-Pedal Driving9

HUMMER EV is the first GMC vehicle to offer Regen on Demand5 and One-Pedal Driving – both driver-controlled braking features, which can convert the kinetic energy of the truck’s forward momentum into electricity stored in the vehicle’s battery packs to maximize the driving range.

With the pull of a steering wheel paddle, Regen on Demand can slow the vehicle to a full stop without pressing the brake pedal. Similarly, One-Pedal Driving can slow the vehicle to a full stop using the accelerator pedal providing very fine control. The HUMMER EV allows drivers to configure One-Pedal Driving with multiple levels to match the driver’s preference. Combined, these two features provide flexibility and precision control of how the vehicle slows down in normal driving conditions.

Additionally, Terrain Mode uniquely integrates the brake system with One-Pedal Driving, giving the driver precise control while off-roading.

The HUMMER EV is the first full-electric vehicle in GMC’s portfolio and is powered by General Motors’ new Ultium battery system. Production begins in late 2021, at GM’s Factory ZERO, Detroit-Hamtramck Assembly Center10— a nearly 40-year-old facility repurposed and retooled with a $2.2-billion investment devoted to electric vehicle production. Future production vehicles out of the factory will offer zero emissions.

Performance targets, estimates and capability specifications based on computer-aided analysis and simulation using virtual engineering tools. Estimates may vary depending on model and trim. Actual production model and results may vary.