The Lancia Delta was a successful car sold by Lancia from 1979 to 1994 and was designed by Giorgetto Giugiaro. In Sweden, it was sold by Saab Automobile as the Saab 600. Saab also helped with the logistics and as a result, the Delta was better suited for colder climates and less prone to rust than other Lancias. Its key competitors were the Volkswagen Golf, Vauxhall Astra/Opel Kadett and Ford Escort. For a few years after its launch, the Delta was one of the most contemporarily styled cars of its class in Europe.

While the majority of Delta models were ordinary compact family cars, the most famous model was the Delta HF Integrale, a 4WD hatchback with a powerful turbo-charged engine. A tweaked version of the HF dominated the World Rally Championship, scoring 46 WRC victories overall and winning the Constructors Championship six times in a row from 1987 to 1992, a record.

The Lancia Delta S4, while sharing the same name and appearance, was a “Group B” race car designed specifically for rallying, and entirely different from the commercial Delta in terms of construction and performance.

The Delta was voted Car of the Year in 1980.

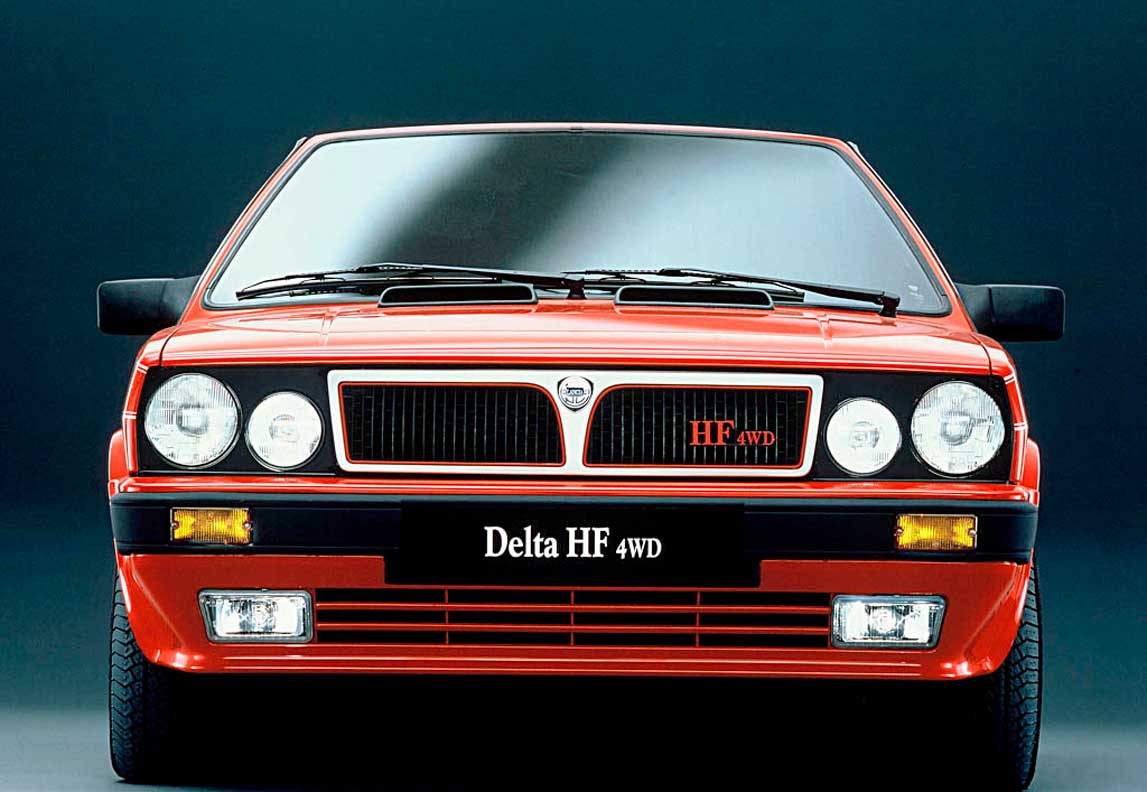

HF4WD

In 1985 the rallying world suffered a tremendous blow in terms of development as FISA decided to scrap plans for a proposed Group S as well as cancelling Group B. It was ruled that Group B cars were too fast and, as a consequence, too dangerous. It turns out that Lancia was one of the more far sighted manufacturers since it already had the HF 4X4 production car in the pipeline, using experience gained from the development of the S4 rally car.

Superseding the Delta HF turbo as the flagship of the Delta range -(S4 excepted)-the HF 4WD had a lot to live up to. ‘The HF Turbo i.e.’ was no slouch and it’s handling was praiseworthy for a front-wheel drive car.

The Delta range was first introduced to the UK in 1980 and remained virtually unchanged until 1986, when small changes were made to the body shape and the engines updated; plus, of course, there was the addition of the four-wheel drive model. One of the features of the HF 4WD is the under-statement of the body treatment.

There is very little to distinguish it from the ‘Turbo i.e.’ apart from the four-headlight system, fog lamps mounted in the front spoiler, discreet 4WD badging on the rear hatch, the small side skirts and two raised air intakes on the bonnet. It is therefore virtually indistinguishable from the 1600cc HF Turbo i.e.

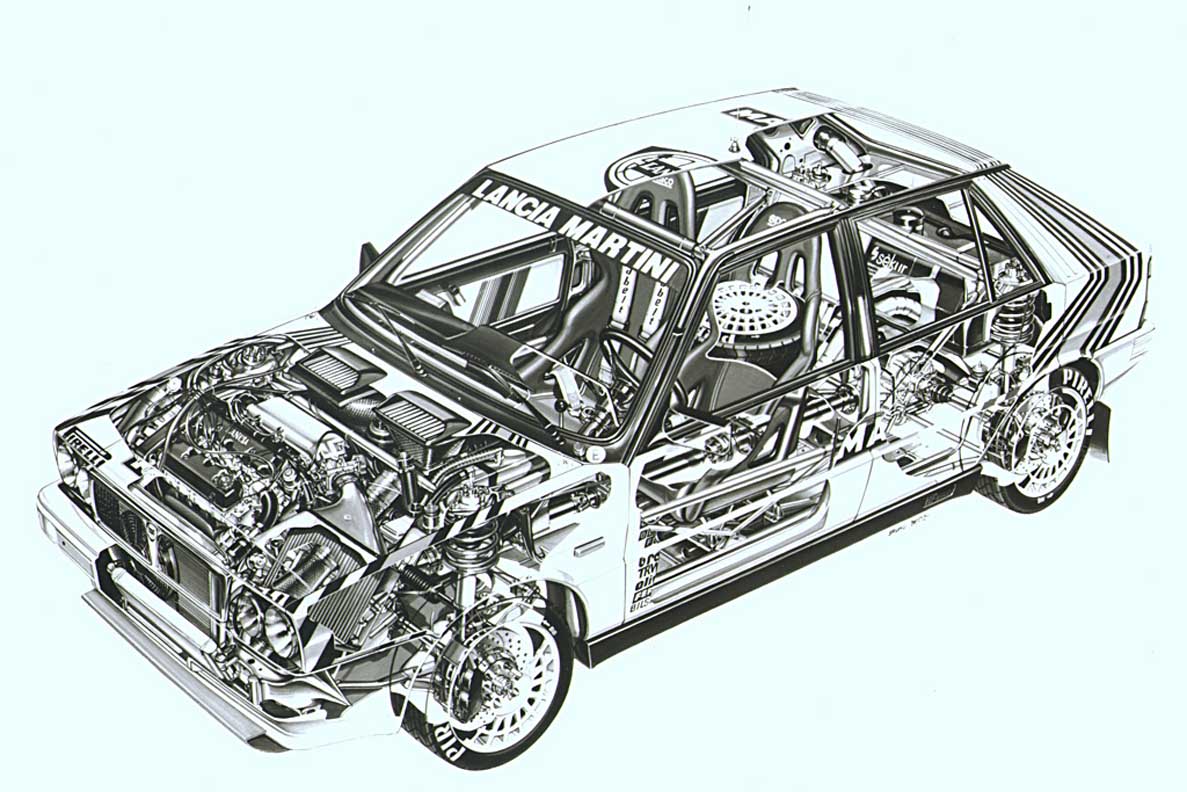

With 165bhp on tap the best way of transfering it to the road is via four, rather than two-wheel drive. In the Delta HF 4X4, Lancia was not content to go for a simple system but rather opted for one with an in-built torque-splitting action to ensure that the available power was going to the wheels with the most traction at any given time, thus ensuring the most efficient use of the available power and torque.

Three differentials are at the heart of the system. Drive to the front wheels is linked through a free-floating differential; drive to the rear wheels is transmitted via a 56/44 front/rear torque-splitting Ferguson viscous-coupling-controlled epicyclic central differential. The real innovation as far as production cars are concerned however, lies between the rear wheels.

The Torsen (torque sensing) rear differential is similar to that found on McLaren Formula 1 cars. The result of combining these differentials in this configuration is an automatic-thinking four-wheel-drive system which requires no manual input from the driver, yet ensures maximum potential traction at any given time.

The Torsen differential is a true ‘intelligent’ differential in the way it distributes torque. It divides the torque between the two wheels according to the grip available and it does it without ever locking fully; maximum lockup is 70 per cent.

Standard differentials are either free-floating or self-locking. Free-floating systems are good at differentiating between wheel speeds on bends, but always supply the same amount of torque to both wheels. In this situation, however, there is a risk that the wheel with the lighter load (on an incline, for example) or less grip, will lose traction. To counteract this possibility, totally self-locking differentials ensure that both wheels rotate at the same speed but in doing this, prevent free differentiation in cornering, to the detriment of handling and stability.

The basic suspension layout of the 4WD remains the same as in the rest of the 2 wheel drive Delta range: Mac Pherson strut-type independent suspension with dual-rate dampers and helicoidal springs, with the struts and springs set slightly off-centre.

There are a few more subtle changes, though, with the suspension mounting points to the body shell, now better insulated by incorporating flexible rubber links to provide improved isolation. Progressive rebound bumpers have also been adopted, while the damper rates, front and rear toe-in and the relative angle between springs and dampers have all been altered. The steering retains the rack and pinion mechanism of the rest of the Delta range, but in this application it is power-assisted. Steering effort has been reduced further by fitting thrust bearings of the ball, rather than roller type. Additional steering sensitivity has also been obtained by adjusting the angle of incidence of the steering rack.

Integrale 8v

Most manufacturers producing a car that wins the World Rally Championship in it’s first season, would rest on their laurels. Not Lancia! Taking the all-conquering Delta HF 4WD that decimated it’s rivals on tarmac, snow, ice and loose surfaces throughout the 1987 season, Lancia designed the HF Integrale to incorporate all the advanced technical features of the rally car enhanced by the lessons learned in the world’s toughest motor sport arena. The result is a stylish, luxurious yet utterly practical five door hatchback with impeccable road manners, but capable of a blistering 0-62 mph acceleration in just 6.6 seconds and a maximum speed of 133 mph.

At the heart of the 8 valve HF Integrale is a two litre 4 cylinder fuel injected twin cam engine, fitted with contra-rotating balancing shafts. This version, of what is surely one of the world’s most competition proven power units, incorporated the following improvements over the HF 4WD: New valves, valve seats and water pump, larger water and oil radiators, more powerful cooling fan and bigger air cleaner. A larger capacity Garrett T3 turbocharger with improved air flow and bigger inter-cooler to aid volumetric efficiency, together with revised settings for the electronic injection/ignition control unit and a knock sensor, boost power output to 185 bhp (DIN) at 5,300 rpm and maximum torque of 3l mkg (224.13 lb ft) at 3500 rpm.

The Delta boasts one of the worlds most advanced transmission systems incorporating permanent 4wheel drive, a front transversely mounted engine and 5 speed gearbox. An epicyclic centre differential normally splits the torque 56 per cent to the front axle, 44 per cent to the rear. However a noiseless, fully automatic Ferguson viscous coupling balances the torque split to give the optimal division between front and rear axles depending on road conditions and tyre grip. The Torsen rear differential further divides the torque delivered to each rear wheel according to grip available. By using the interaction between a worm screw and helical gear (movement is transmitted from screw to gear only ) the Torsen system ensures that the wheel with less weight or grip receives less torque and therefore maintains traction. A free floating front differential completes the system to ensure maximum traction even at speed on adverse road surfaces. A shorter final drive ratio (3.111 instead of 2.944 on the HF 4WD) is used to match the larger 6.5 X 15 wheels to give 24 mph/1000 rpm in fifth gear. Both braking and suspension were uprated to match the HF Integrale’s increased performance. The ventilated front discs were increased in diameter to 284 mm, improved friction coefficient pads were fitted to the rear brakes. A larger brake master cylinder and servo lessened pedal effort for quicker response and reduced the risk of overheating in even the most demanding situations. The all round independent suspension features new front springs, dampers and front struts.

In line with the mechanical improvements and higher performance, Lancia gave the HF Integrale a new, more purposeful look while retaining all the practical advantages of the five door body shell. Immediately noticeable are the rounded, bulged wheel arches housing the wider section 195/55 VR tyres on 15 inch 6J alloy wheels. A new bonnet incorporated air louvres while the restyled bumpers wrapped around to meet the wheel arches at front and rear. The front bumper, now wider, incorporates air intakes to assist engine cooling, and houses rectangular auxiliary driving lights, that compliment the twin circular headlights. The side skirts are faired into the wheel arches at front and rear and carry “Delta HF Integrale” badges to compliment those on grille and rear hatch. The twin rear view mirrors are finished in body colour.

Integrale 16v

In 1988, Lancia gained 10 victories out of 11 rallies and the world title, won well before the end of the season. The 8 valve Delta had won, ahead of every rival in every continent, demonstrating its unrivalled performance, reliability and durability. But Lancia did not let this lull them into complacency, the l6 valve HF Integrale was being developed and was to run alongside its stablemate during the 1989 season. The new car was identifiable from its predecessor by the raised centre of the bonnet to accommodate the new 16 valve engine. The other exterior changes visable were; wider wheels and tyres and new identity badges front and rear.

The torque split was changed to 47% front and 53% rear, this gave the car better handling characteristics, on tarmac, where the Ford Cosworths were begining to show their potential. Both the 8 and 16 valve cars were in use by the Works Team during the 1989 season, the 16 valve made it’s successful debut on the Sanremo Rally with Miki Biasion, at this time the new livery of the 16 valve cars was red, the colour reverted to white for 1990 as red was found to be less incisive than white in photographs and on television.

The turbocharged 2-litre Lancia 16v engine is already a powerful, refined performer, but was further developed for the Integrale 16v. Generating 200 bhp at 5500 rpm, it can take the car to a maximum speed of 137 mph (220 km/h) and get it from 0-62 mph (0-100 km/h) in 5.7 seconds. Larger injectors provide higher power output and efficient exploitation of the fuel feed at high engine speeds.

The response of a Garrett T3 turbo is immediate, thanks to the reduced inertia of the turbine. A highly efficient intercooler provides the driver with more power and greater reliability. The new over-boost system uses a proportional electrovalve, to give a lift to engine torque: 220 lbft at 3000 rpm. All these improvements make the road-going version of the Integrale 16v a spirited, reliable and inherently safe car. The exuberant 16-valve engine, however, retains commendable refinement, thanks to the inclusion of two counter-rotating balancer shafts, eliminating vibration to give superb smoothness. The engine can also run on unleaded fuel without modification.

The Lancia Delta HF Integrale 16v uses a dual circuit braking system with each axle separate, which is safer because directional stability is maintained by each axle. The optional four-channel, second generation ABS system is mounted on this circuit. Designed specifically for four-wheel drive, it ensures safe braking on all surfaces and in any situation, in the minimum distance, to maintain directional stability.

In emergency braking, the electronic control unit uses two sensors, detecting transverse and longditudinal accelerations to deliver braking pulses appropriate to each side of the vehicle. Loss of control over ground with uneven grip can thus be prevented. The sensors are situated at the car’s centre of gravity, near the gear lever. System efficiency is assured by electronic self diagnosis carried out automatically after starting the engine.

Integrale Evoluzione

The first Evoluzione cars were built at the end of 1991 and through 1992, these were to be the final Homologation cars for the Rally Team, the Catalytic Evoluzione II was never to be rallied by the Factory.

In order to improve the handling, the vehicles had a wider track front and rear, to enclose this track in the bodywork the wide arches were extended even further, in the process they also became more rounded and the wings were made in a single pressing, previously they had been fabricated.

The front strut top mounts were also raised in the quest for more grip this then required a front strut brace to control the forces thus generated.

External changes included: new grilles in the front bumper to improve the air intake for engine compartment cooling, the bonnet was also redesigned and new lateral air slats assisted this better ventilation.

An adjustable roof spoiler was added above the tailgate to assist in competition and to emphasise the cars sporty lines. New 5 bolt wheels derived from the rally cars were added, these are stronger than the previous wheels. Finally the rear view of the car changed with only one exhaust pipe now showing.

The new Integrale retained the four wheel drive layout: – epicyclic centre diff with torque splitter (47% to front, 53% to rear) and Ferguson viscous coupling, – Torsen rear differential.

The engine though technically the same 16V, was remapped to give 210 bhp at 5750 rpm to compensate for the cars slight increase in weight and frontal area, this kept the performance figures virtually unchanged

The above improvements were aimed at and did change the cars’ handling potential, the car was able to travel 5-6% faster on the rally sections, both on tarmac and gravel and thus, give even greater confidence to the driver when driven in normal road conditions.

Interior trim was now Grey Alcantara as standard covering the same Recaro seats as in the 16V cars, Leather and Air Conditioning was offered, as an option. The interior was finished with a new anotomic grip gear lever and leather covered Momo steering wheel.

There were a number of these cars built to meet Swiss regulations that were equipped with an 8valve catalytic engine giving 165bhp, they are a little underpowered for weight of the car.