Toyota Motor Corporation (Toyota) recently held a technical briefing session, “Toyota Technical Workshop,” under the theme “Let’s Change the Future of Cars” and announced a variety of new technologies that will support its transformation into a mobility company.

Hiroki Nakajima, Executive Vice President and Chief Technology Officer, explained Toyota’s technology strategy and the direction of future car manufacturing. In addition, he spoke on specific and diverse technologies, including concepts under development, which will help achieve the vision and policies that have been communicated so far. Also speaking were Takero Kato, who has been appointed president of the newly established BEV Factory, and Mitsumasa Yamagata, who is scheduled to be appointed president of the Hydrogen Factory to be launched in July. They elaborated on their respective strategies for the battery EV and hydrogen businesses.

Presentation

Toyota’s Technology Strategy and Car Manufacturing Direction

Hiroki Nakajima, Executive Vice President and Chief Technology Officer

An explanation of the “Toyota Mobility Concept” was given at the policy briefing in April. The three approaches that hold the key to its realization are electrification, intelligence, and diversification.

In the area of electrification, we will continue to pursue a “multi-pathway approach,” including the introduction of optimal powertrains for each region.

In the area of intelligence, in addition to vehicles and services, we will also promote initiatives to expand our connection with society, such as Woven City.

We will also continue to diversify our business by expanding our scope from “cars” to “society” to include freedom of mobility and diverse energy options for all.

To promote these three themes technologically, we have been shifting resources to Advanced Development fields and actively investing in future-oriented areas since 2016, when the company system was inaugurated.

As of March 2023, we have shifted more than half of our R&D staff and approximately half of our R&D expenses to Advanced Development fields while increasing the total amount. We will further accelerate this trend in the future.

We would like to promote car manufacturing based on three axes. The first is to pursue safety and security without compromise. We will further refine Toyota Safety Sense and deliver safe and reliable technologies to our customers. The second is that the future will be built by everyone. We will create the future by connecting with our colleagues around the world through initiatives such as CJPT’s efforts to decarbonize the commercial sector, our partnership with the CP Group in Thailand, and our collaboration in motorsports. Third, we will accelerate localization. As the needs of our customers in each region will differ further in the future, we will accelerate “development near our customers” at our research and development bases around the world.

Toyota has overcome what were thought to be difficult challenges with its technological capabilities and has developed numerous vehicles that are ahead of the times and paving the way for the future, such as the Prius, now synonymous with hybrid vehicles, and the Mirai fuel cell vehicle. Let’s change the future of cars! We will continue to lead in creating a future society by using the power of technology to transport our customers into the future and connecting cars to society.

What we hope to achieve with BEV Factory, an organization dedicated to battery EVs launched in May, is to change the future with BEVs through the transformation of cars, manufacturing, and the way we work.

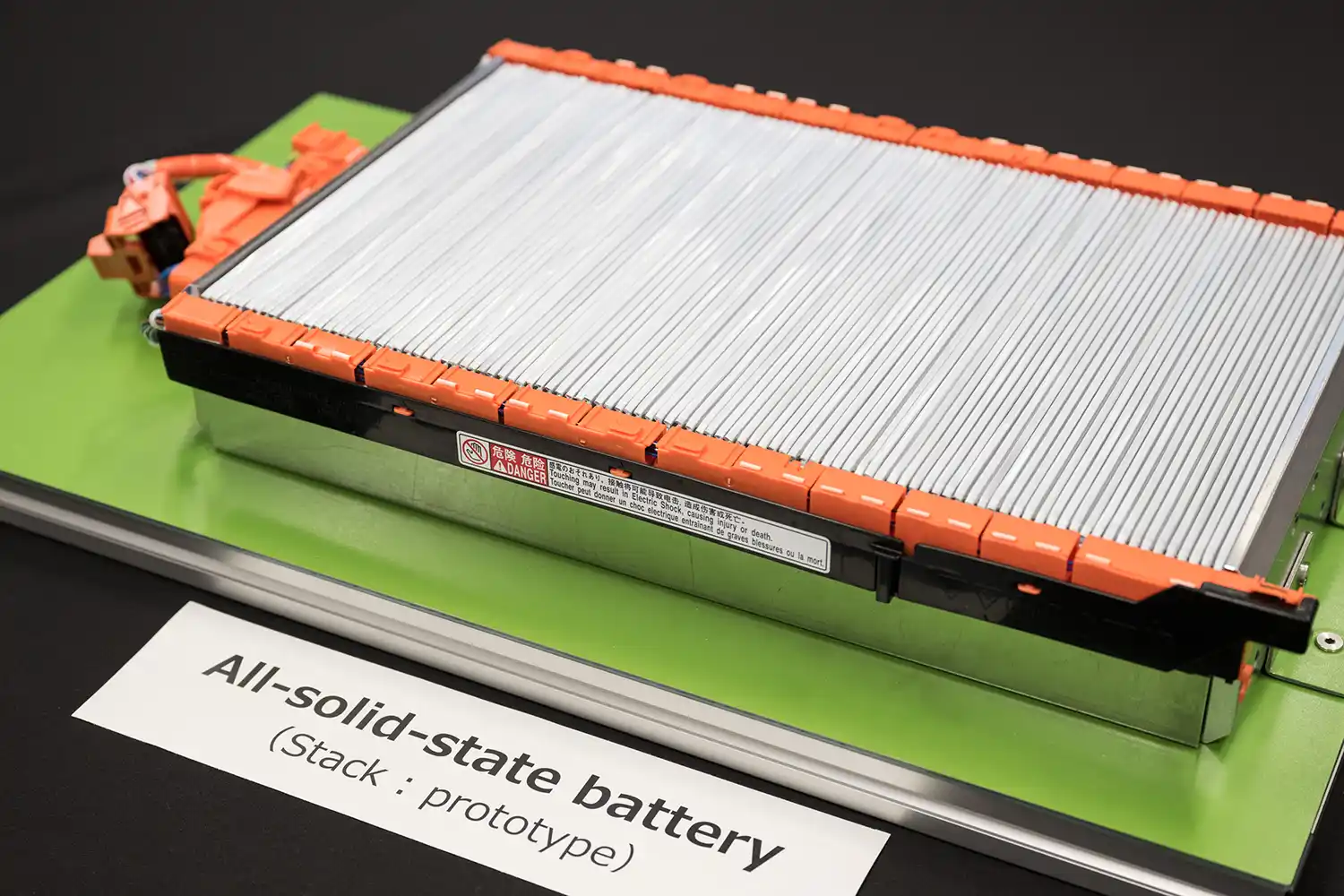

On the vehicle axis, through technologies such as the integration of next-generation batteries and sonic technology, we will achieve a vehicle cruising range of 1,000 km. To bring more stylish design, Aerodynamic performance is supported by AI, while designers will focus on expressing natural sensibility. The Arene OS and full OTA will infinitely expand the possibilities for enjoying cars.

Like the manual EV, we will deliver exciting surprises and fun to our customers with technologies achievable only by a carmaker.

On the manufacturing axis, the car body will be constructed from three main components in a new modular structure. Adopting giga casting will allow significant component integration, which contributes to the reduction of vehicle development costs and factory investment. In addition, self-propelling production technology will reduce the processes and plant investment by half.

BEV Factory is an “ALL in ONE TEAM” under one leader that unifies functions and regions beyond the framework of a carmaker, including WOVEN by TOYOTA and external partners.

This ONE TEAM will revolutionize the way work is done, with everyone on the same site and with the same awareness of the issues, to achieve quick decision-making and initial response.

We will roll out next-generation BEVs globally and as a full lineup to be launched in 2026. By 2030, 1.7 million units out of 3.5 million overall will be provided by BEV Factory.

The next-generation battery EVs will adopt new batteries, through which we are determined to become a world leader in battery EV energy consumption. With the resources we earn, we will improve our product appeal to exceed customer expectations and secure earnings.

Please look forward to a “carmaker-produced battery EV that inspires the hearts of all customers.”

Hydrogen Business Strategy

Mitsumasa Yamagata, Hydrogen Factory President (to be appointed on July 1, 2023)

The hydrogen markets in Europe, China, and North America will be by far the largest in 2030, and the fuel cell market is expected to expand rapidly toward that point, reaching the level of 5 trillion yen per year. We are promoting external sales of fuel cells using the Mirai’s hydrogen units and have received offers for external sales of 100,000 units by 2030. Most of them are commercial vehicles.

To respond to the rapid changes in the market, we will establish a new organization called Hydrogen Factory in July, which will be able to make immediate decisions under one leader, from sales to development and production, all at once. The Hydrogen Factory will promote business on three axes.

The first is localizing R&D and production in countries within the major markets. We will accelerate our efforts by establishing local bases, mainly in Europe and China.

The second is strengthening alliances with leading partners. We will do our best to deliver affordable fuel cells to our customers by consolidating sufficient quantities through alliances.

The third is competitiveness and technology.

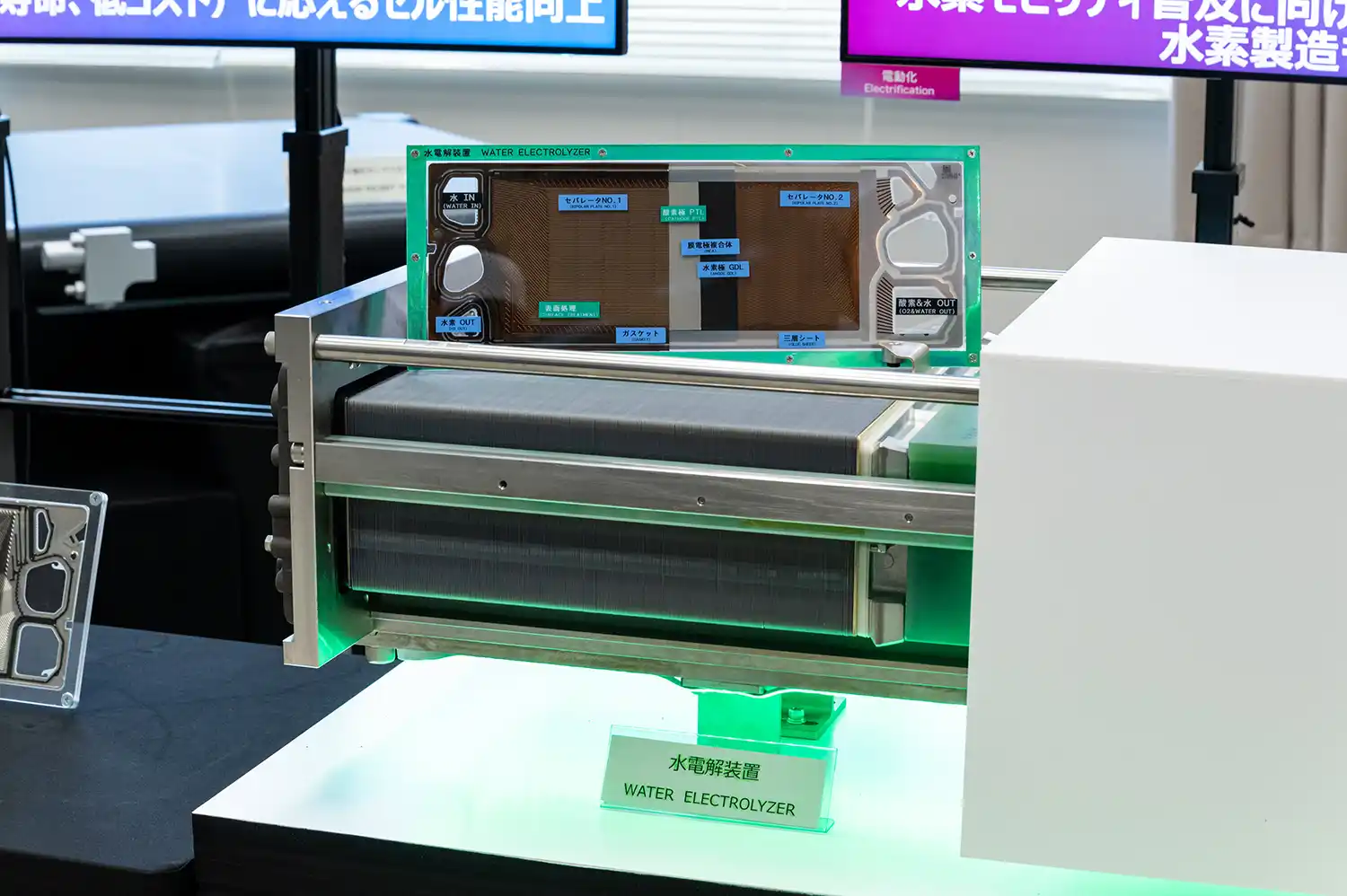

We will work on “innovative evolution of competitive next-generation FC technologies,” such as next-generation cell technologies and FC systems.

We will work toward full-scale commercialization as we move forward with these initiatives. The next-generation system will achieve a 37% cost reduction through technological progress, volume efficiency, and localization. Furthermore, in collaboration with partners, if we receive an offer for 200,000 units in 2030, we will be able to reduce the cost by 50% and generate a solid profit while meeting the expectations of our many customers and governments.

We will work together in development, production, and sales to achieve this goal.

In addition, the price of hydrogen is still very high. In order to promote the widespread use of hydrogen, Toyota will continue to work with its partners to contribute in producing, transporting, and using hydrogen.

We will take relationships we have built with strong partners as opportunities to accelerate our efforts to commercialize hydrogen by establishing customer-oriented bases in major markets and by offering affordable products in sufficient quantities.