The Bugatti Tourbillon packaging strategy redefines what’s possible in a hypercar. From the engine layout to aerodynamic mastery, every decision reflects Bugatti’s relentless pursuit of perfection. This isn’t just a car, it’s a masterclass in seamless integration.

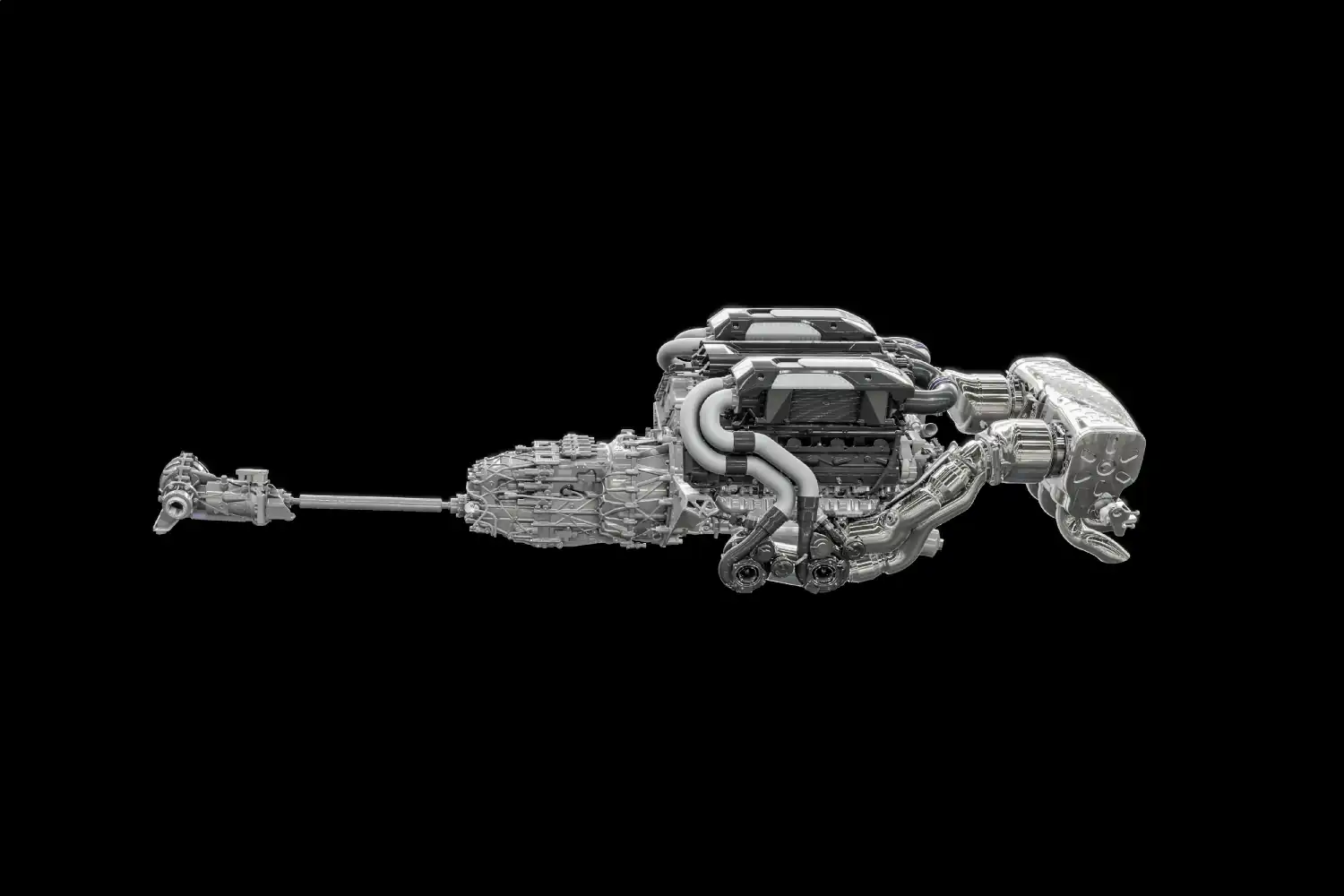

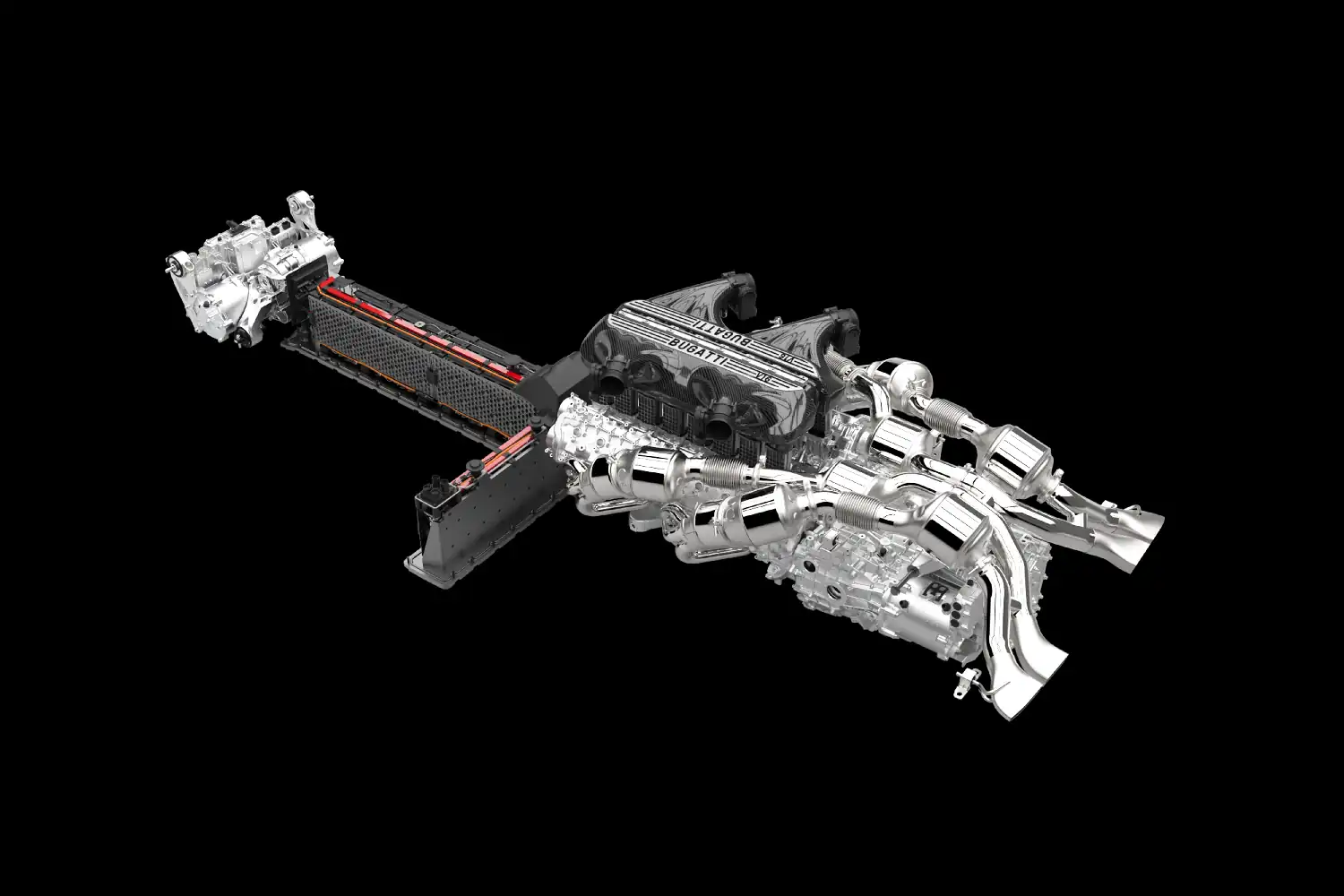

New V16 Engine and Radical Layout Choices

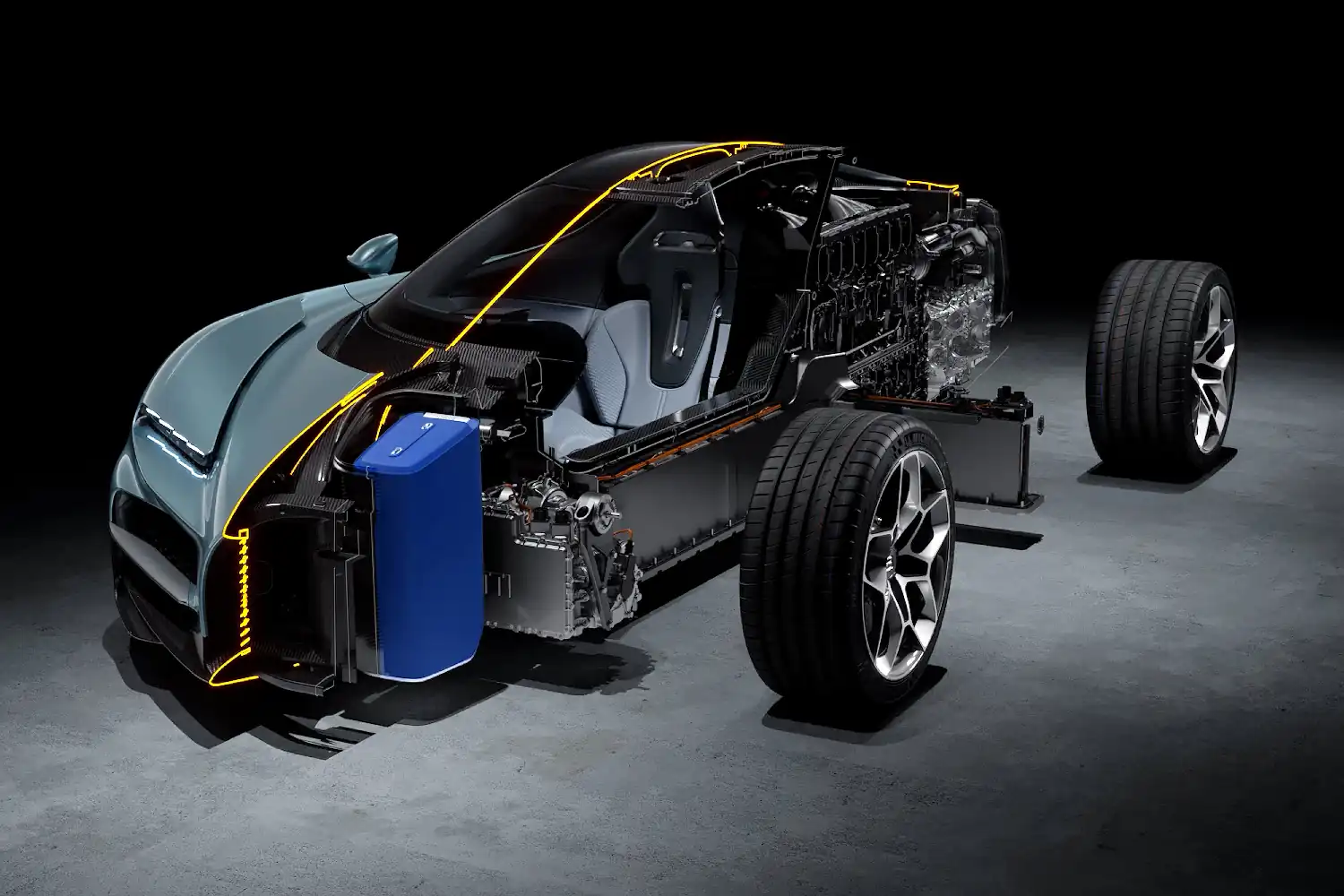

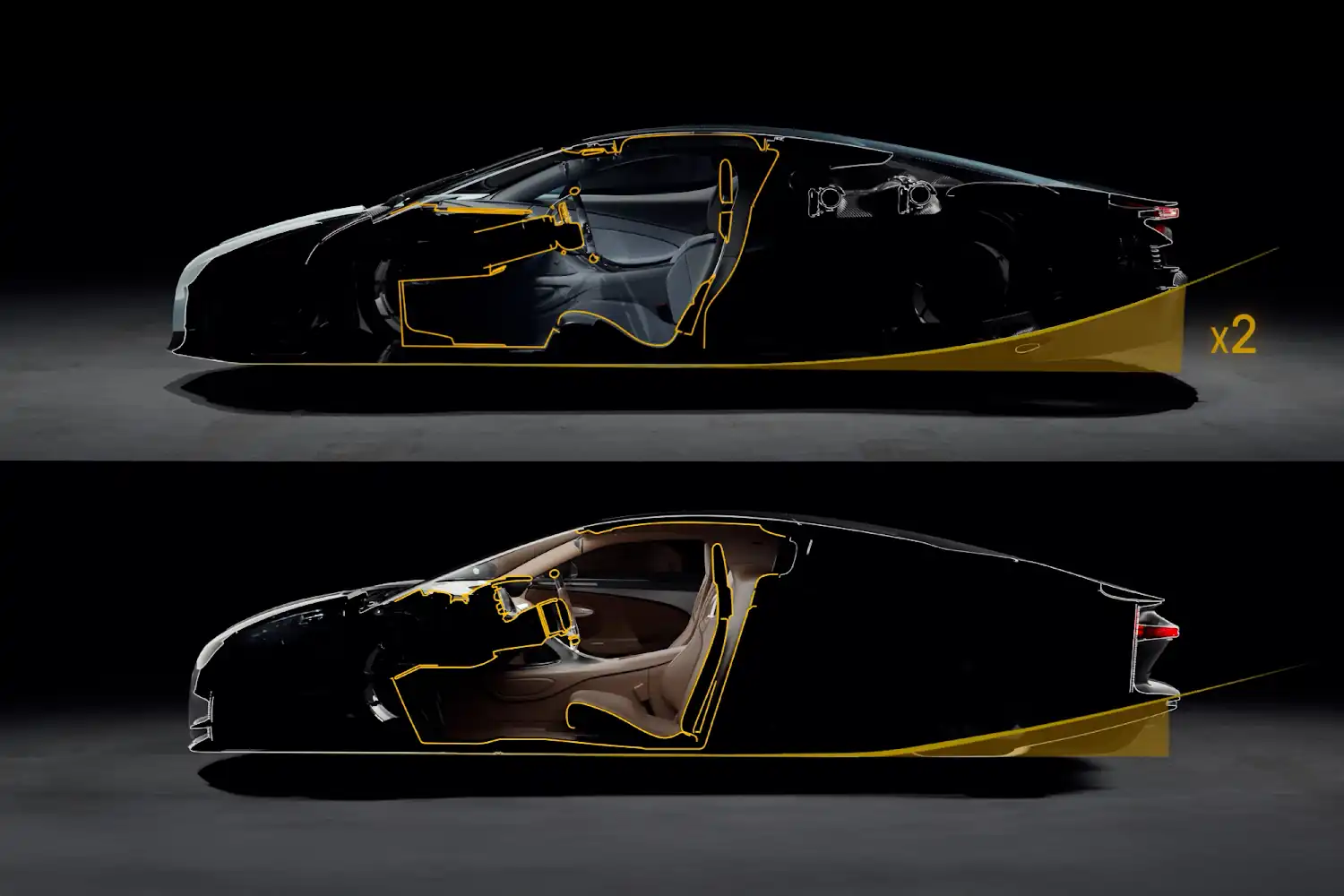

At the heart of the Tourbillon sits an all-new V16 engine. Unlike the previous W16, this one is longer, narrower, and mounted at an angle. That change sounds minor, but it transformed the car’s entire packaging. It allowed for the development of ultra-long Venturi tunnels that begin under the cabin and extend halfway down the car.

These tunnels generate powerful downforce from underneath, reducing the need for a large rear wing. The result? Less drag and more speed. The Tourbillon achieves its top speed without ever raising the rear wing, something few hypercars can claim.

Powertrain and Aerodynamics, Reimagined

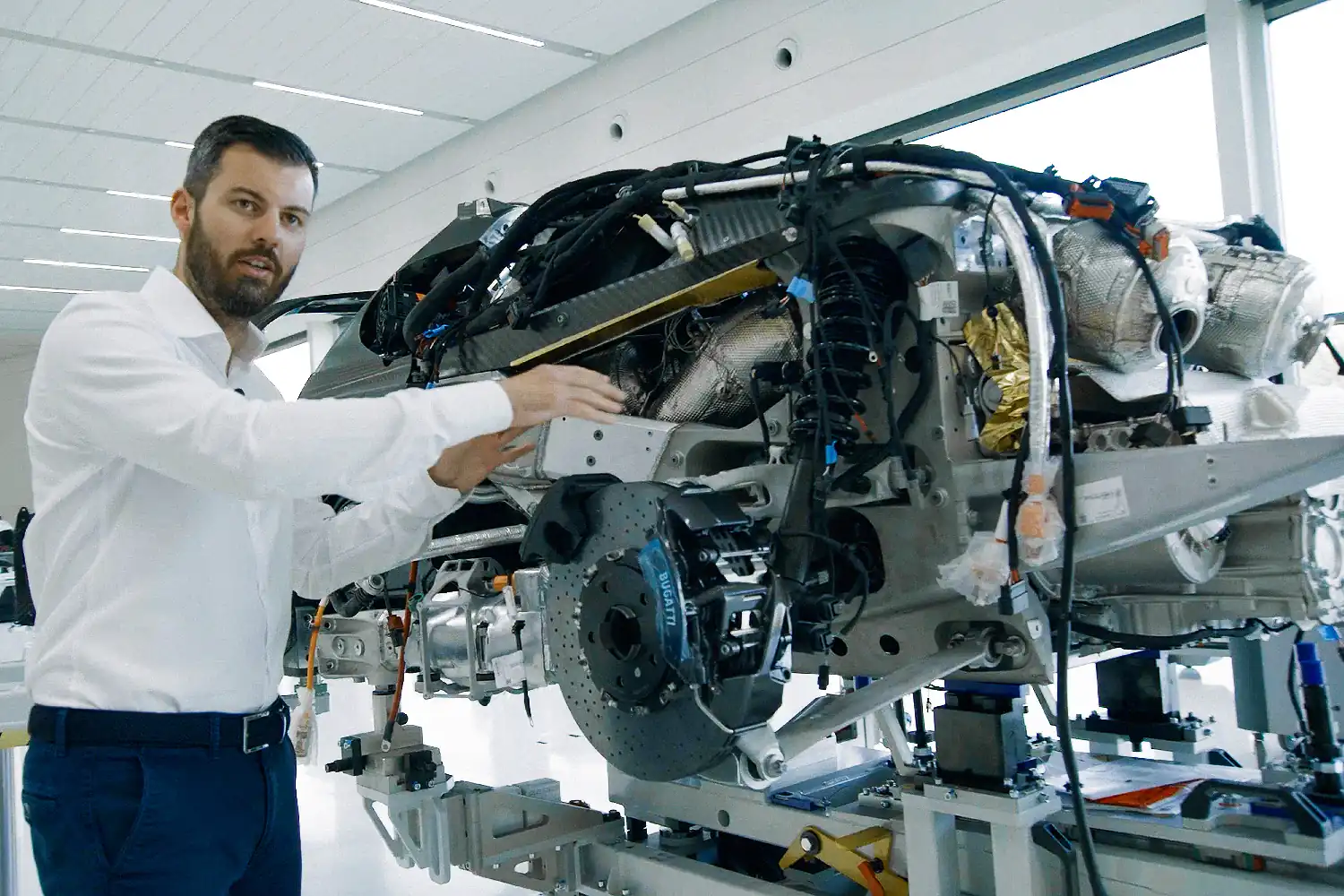

To support this new layout, Bugatti engineers moved the gearbox behind the engine. The front axle gets its power from two electric motors, completely independent of the combustion engine. Between them sits a compact battery. This setup improves packaging, optimizes weight distribution, and enhances agility.

The reduced frontal area is key to speed. It might seem like a small detail, but even minor improvements in this area significantly affect resistance and top-end performance. Aerodynamics, thermodynamics, and structure all converge in the Tourbillon’s front design.

Packaging as Performance: The Front and Rear

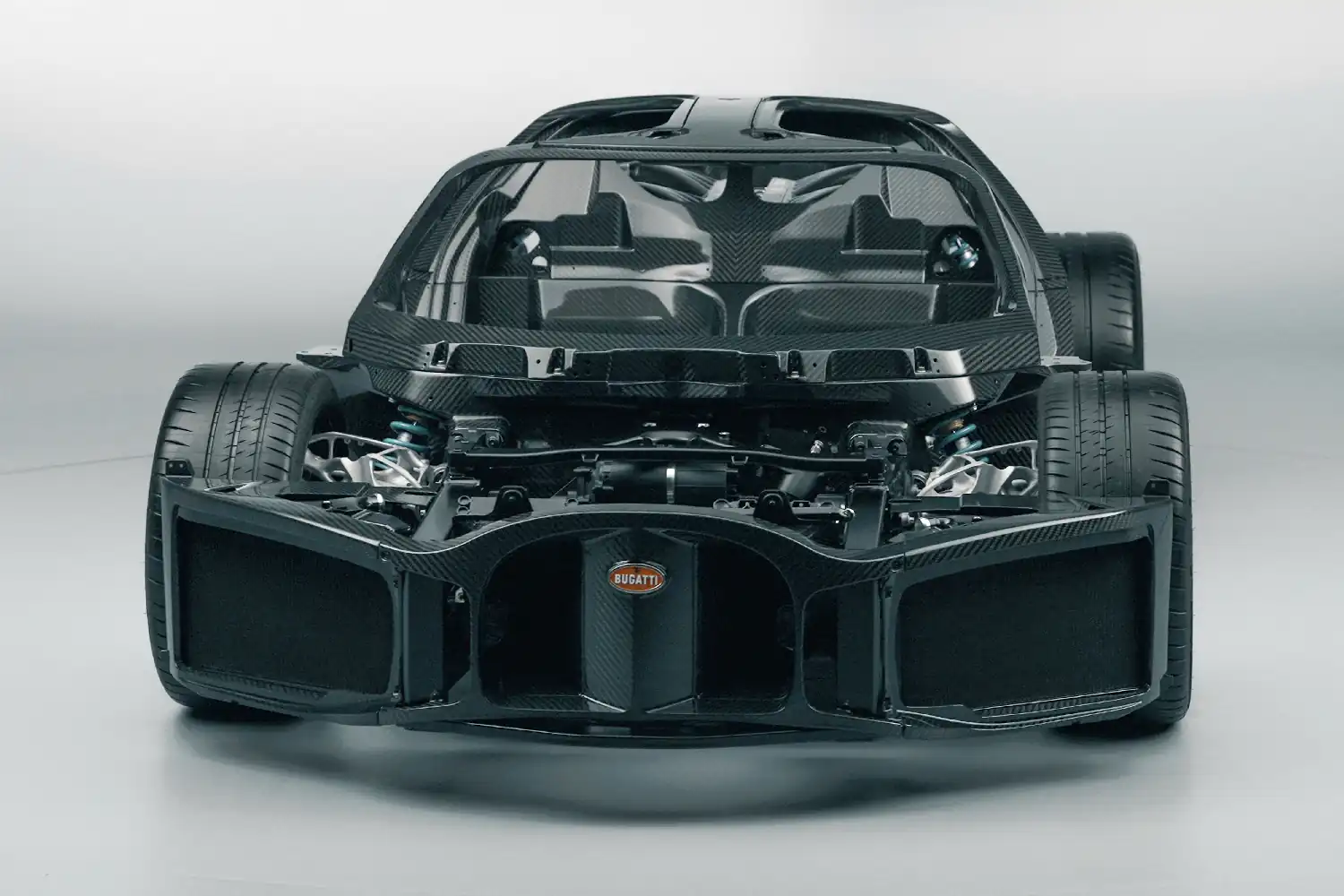

The front grille, shaped like Bugatti’s iconic horseshoe, is more than a signature. It’s functional. Air flows through it to cool the luggage bay, battery, and front electric motors. Even the suspension design supports airflow. Components are airfoil-shaped and exposed, reducing drag without compromising strength.

At the rear, Bugatti does away with a traditional crash beam. Instead, the rear diffuser doubles as a structural element. It features two 3D-printed metal crash absorbers that protect without adding excess weight.

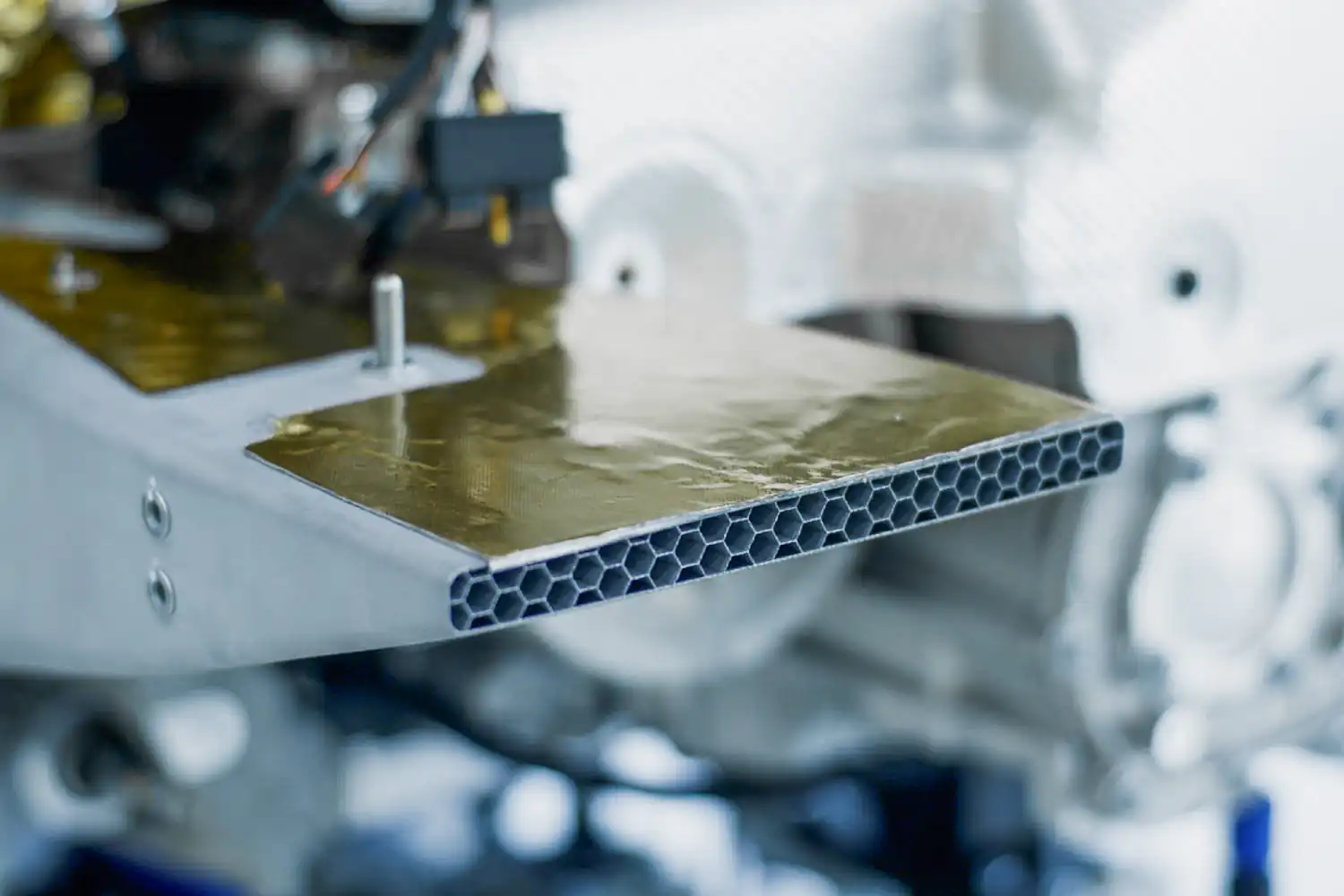

AI and 3D Printing for Lightweight Strength

Bugatti used artificial intelligence to sculpt parts from the inside out. Engineers removed every unnecessary atom. The result? Suspension wishbones and structural elements that are as light as they are strong.

These organic, micro-structured parts look like something from nature, but they’re engineered with precision. It’s proof that software, design, and performance can coexist in perfect balance.

Summary

The Bugatti Tourbillon packaging strategy isn’t just about fitting parts into a shell. It’s about creating a car where every element serves a greater purpose. From its angled V16 to 3D-printed crash structures, this is a car where engineering meets artistry.

Disclaimer: Technical details described reflect early production specifications and may change in final versions.

Source: Bugatti