Rimac Technology solid-state battery innovations are taking center stage at IAA Mobility 2025. The Croatian EV leader is presenting advanced battery systems, next-generation e-Axles, and cutting-edge electronics, reinforcing its role as a leading tier-1 supplier for global OEMs.

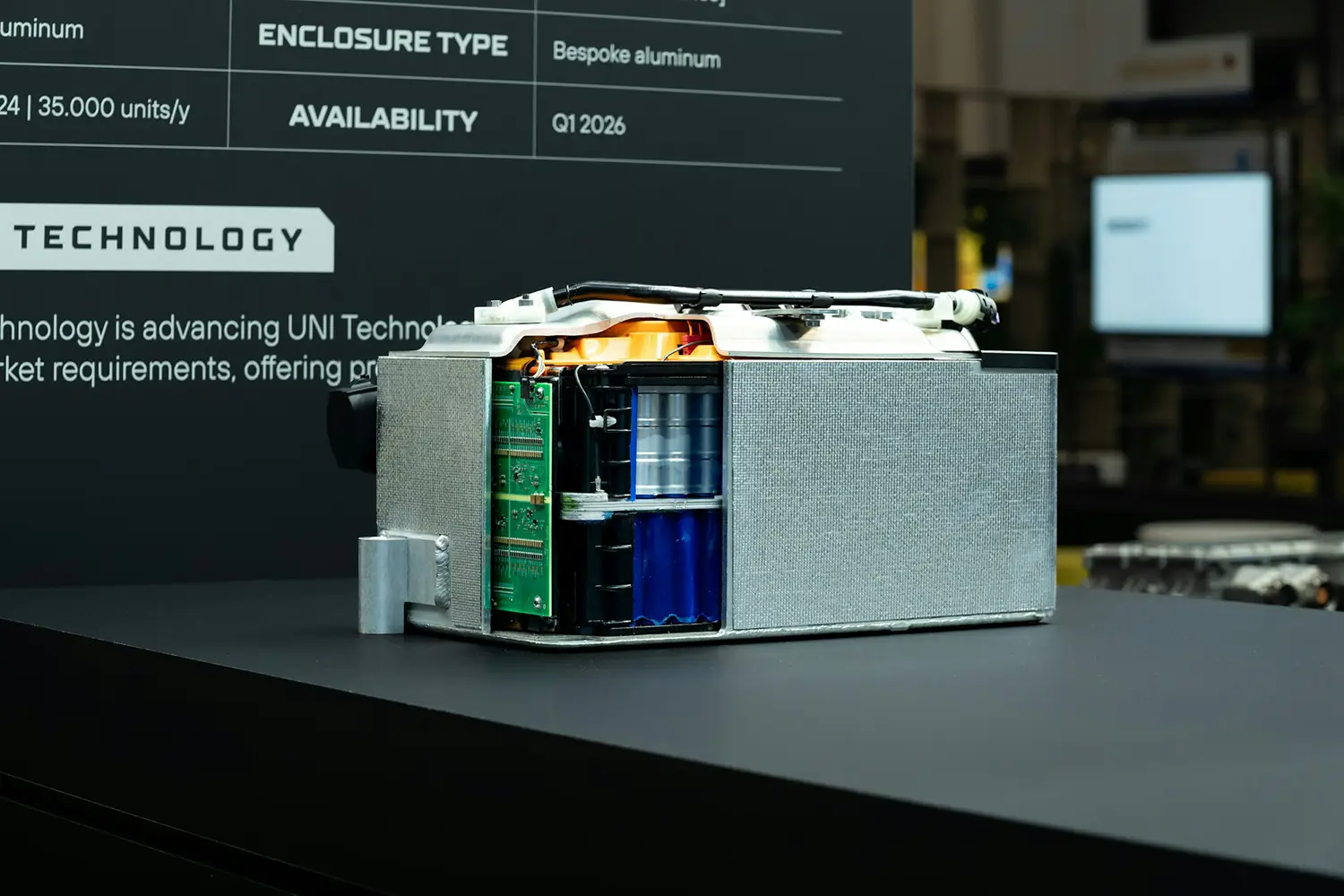

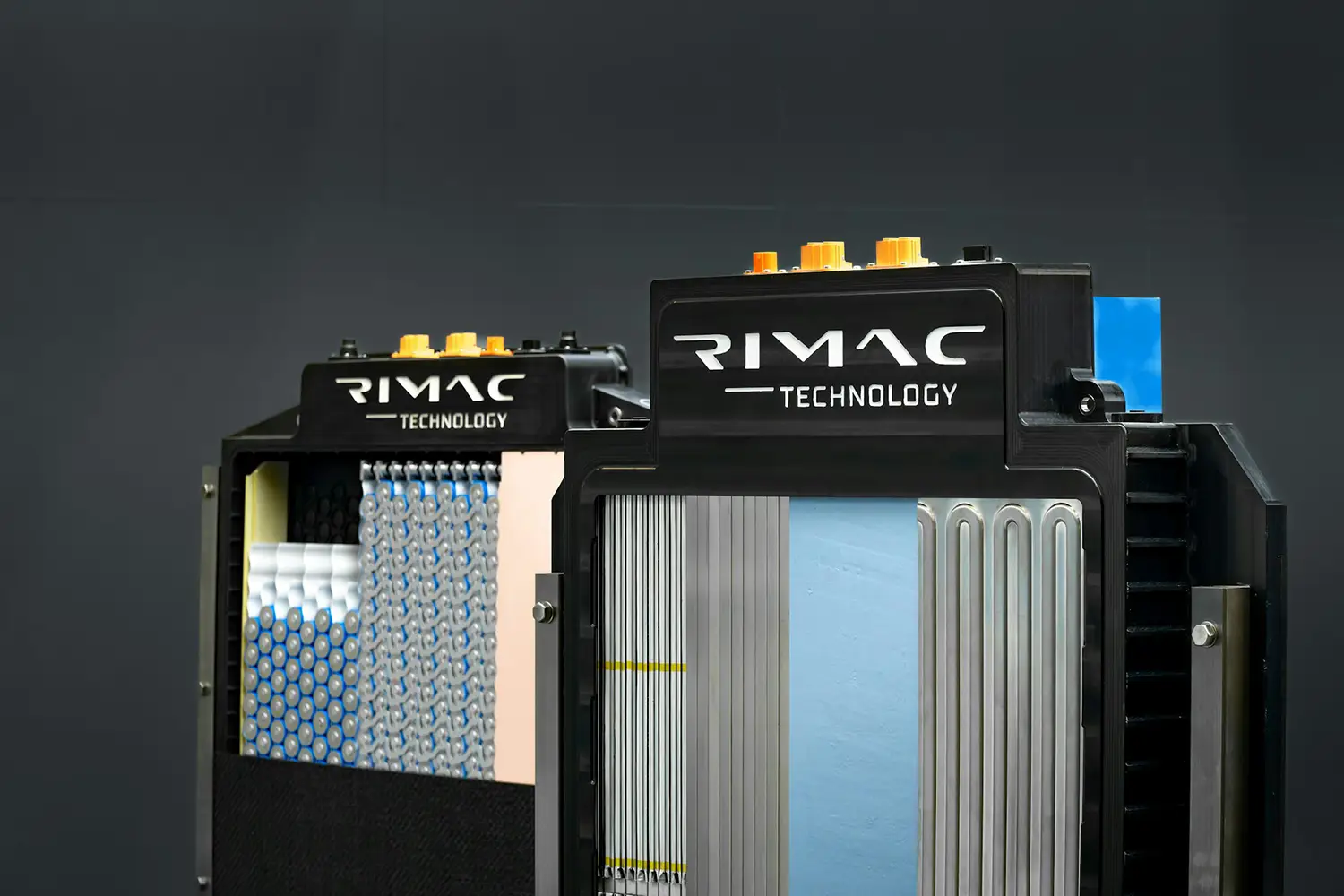

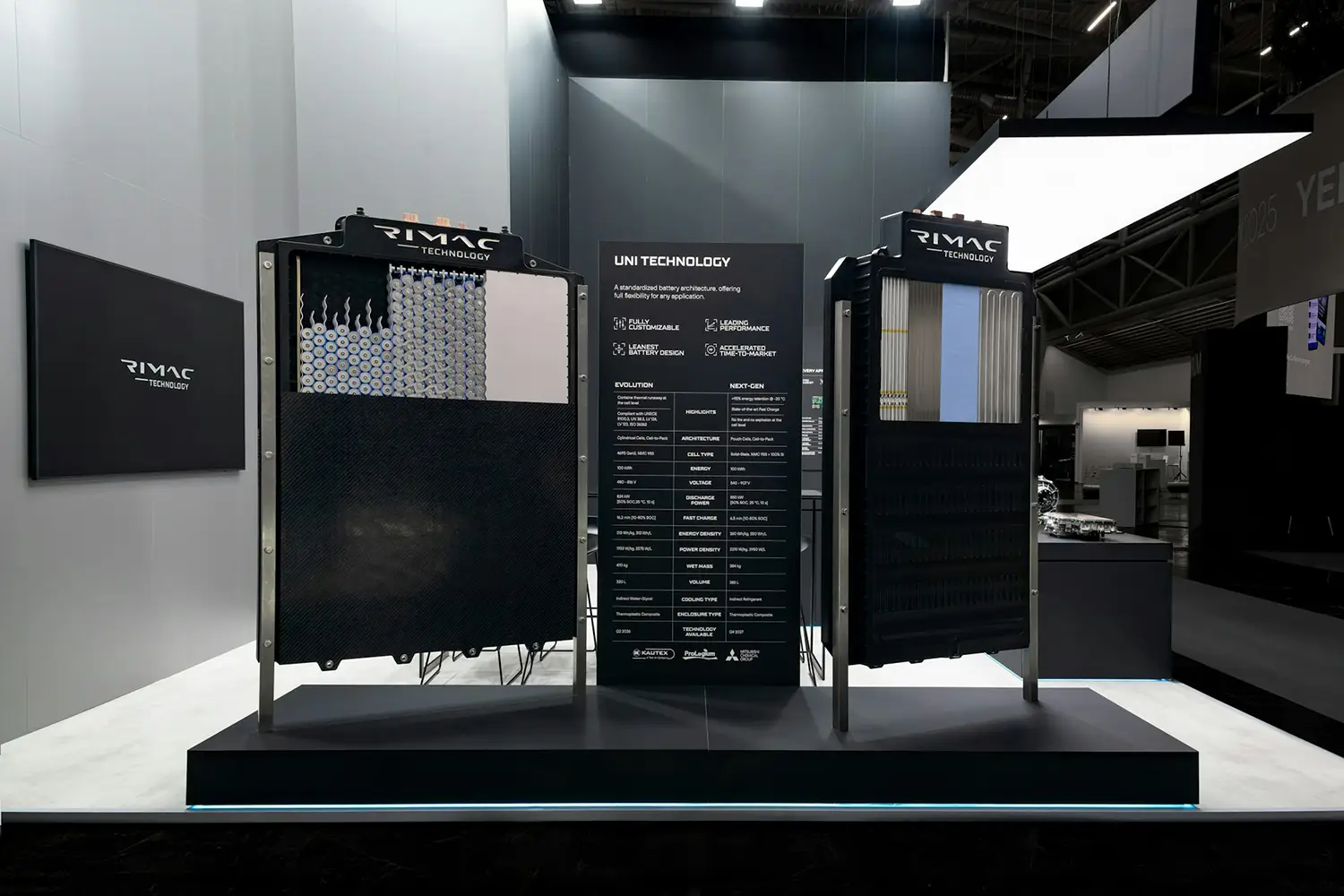

Next-Generation Battery Technology

The Rimac Technology solid-state battery represents a major leap in energy density, safety, and performance. Developed in collaboration with ProLogium and Mitsubishi Chemical Group, these batteries are lighter and safer, offering exceptional efficiency for high-performance electric vehicles.

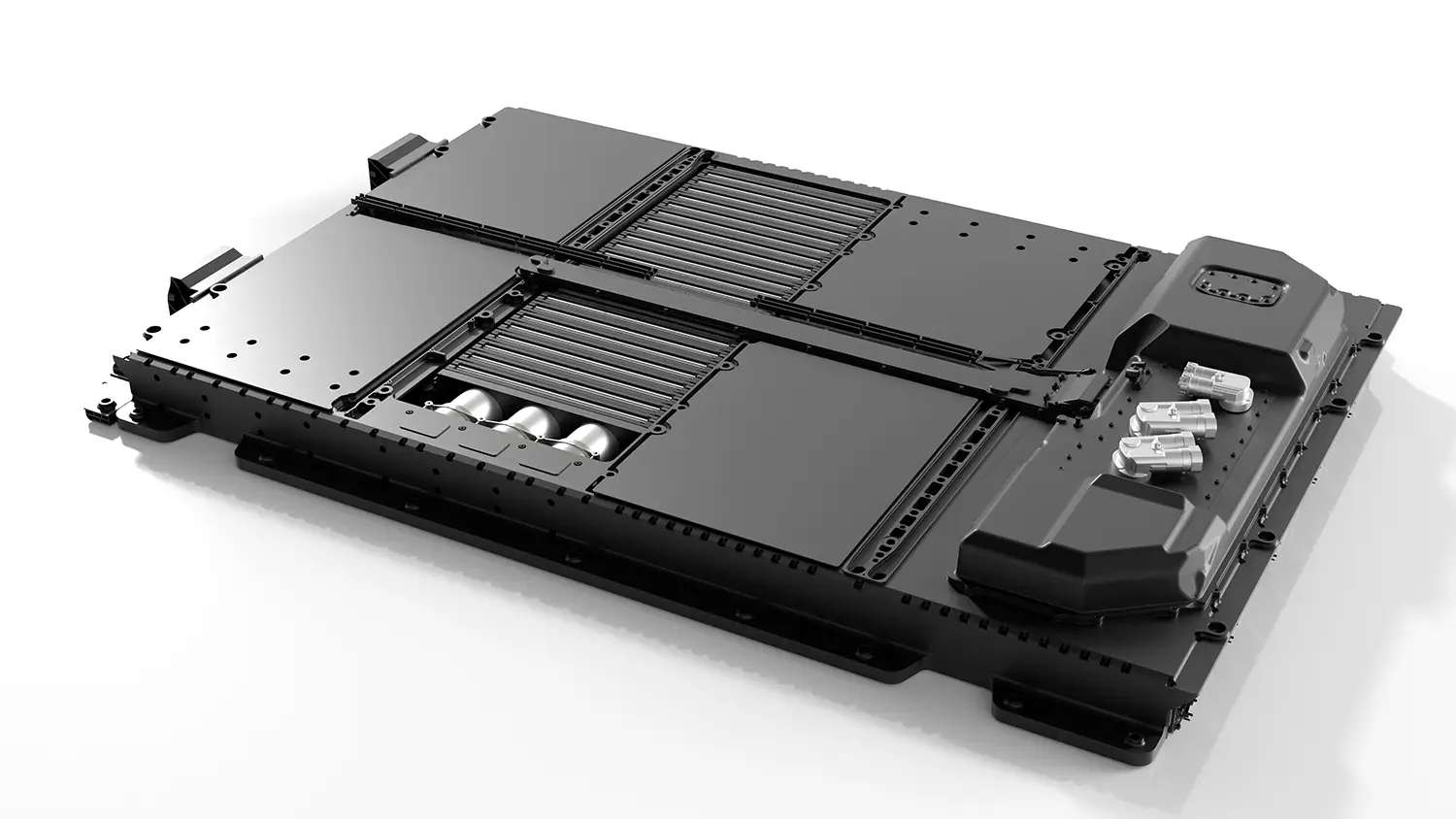

Evo and Hybrid Platforms

Beyond solid-state solutions, Rimac has evolved its existing 46XX Gen2 NMC battery platforms. Featuring thermoplastic composite housing co-developed with Kautex Textron, these systems provide advanced thermal management and scalability for both hybrid and fully electric applications. Hybrid packs based on the 46XX and 2170 formats balance energy density with power output, ensuring flexibility across vehicle types.

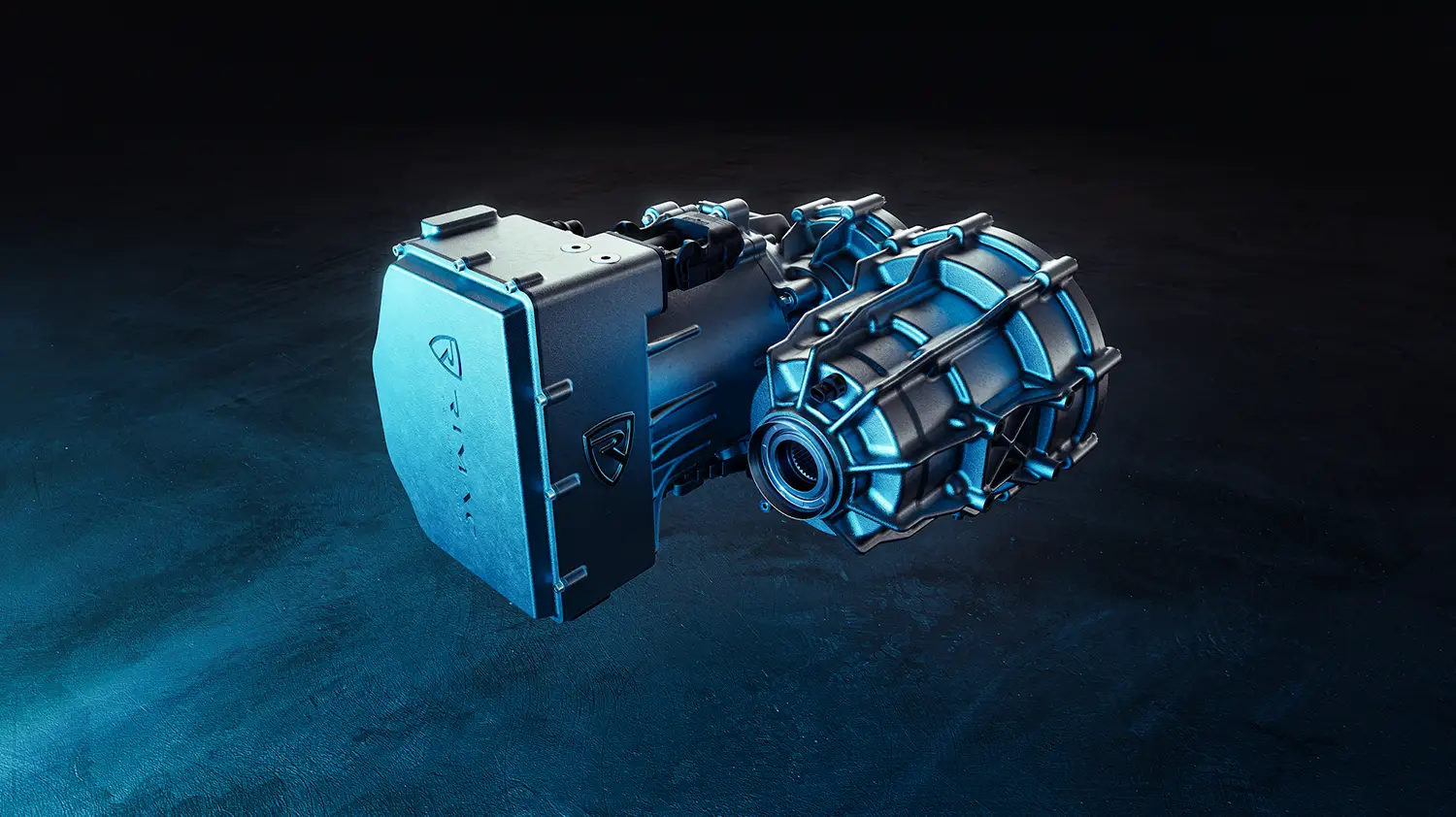

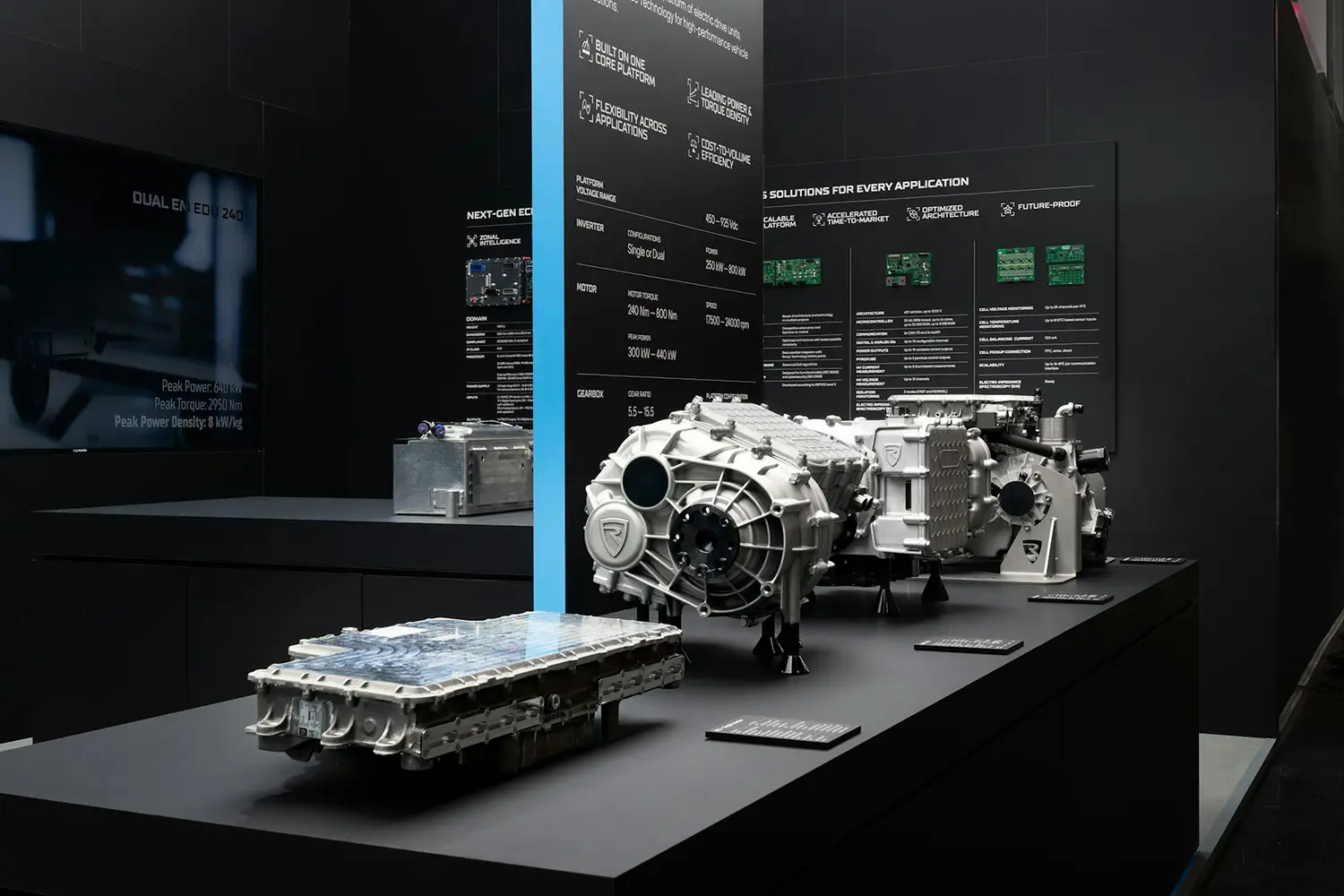

e-Axle Innovations

Rimac’s SINTEG 300 and 550 e-Axles set new industry benchmarks. Delivering over 8 kW/kg power density and 90 Nm/kg torque density, these ultra-compact systems achieve exceptional performance. Their patented ultra-light rotors spin up to 25,000 rpm, producing torque and power rivaling much larger drivetrains.

High Torque XXL Axle

The Dual EM EDU 550 e-Axle, slated for series production in 2026, delivers over 11,000 Nm of axle torque with >95% peak efficiency. This mid-volume production system leverages Rimac’s automated global supply chain, providing performance suitable for a wide range of performance-focused vehicles.

Advanced Electronics and Controls

Rimac Technology’s domain and zonal ECUs consolidate multiple traditional ECUs into high-performance controllers. Using NXP’s S32E2 processors, these controllers manage torque vectoring, high-voltage battery systems, and body electronics, while ensuring OTA updates and software-defined vehicle capabilities.

Production-Ready Solutions

The technologies unveiled are fully production-ready, manufactured in Rimac’s 95,000 m² facilities in Croatia. The Rimac Campus, backed by €200 million in investment, supports multiple high-volume projects, ensuring scalability and reliability for OEM partners.

Industry Impact

Rimac Technology continues to collaborate with global OEMs, including BMW, CEER Motors, and Porsche. By combining innovation, scalability, and performance, Rimac sets a new standard for electrification and positions itself at the forefront of the EV revolution.

Summary

Rimac Technology solid-state battery and e-Axle platforms demonstrate a convergence of innovation, efficiency, and production readiness. IAA Mobility 2025 showcased the future of EV performance, with solutions capable of powering hundreds of thousands of vehicles worldwide.

Disclaimer: Content on this site is for informational purposes only. Vehicle specs, pricing, and availability may change. Always verify details with official sources before making decisions. Opinions are those of the authors.

Source: Rimac