BMW is not just embracing the electric future; they’re actively shaping it. At their Tech Days event in Landshut, the German automaker unveiled its sixth-generation BMW eDrive technology, a revolutionary advancement that promises to redefine electric driving. This isn’t just an incremental improvement; it’s a quantum leap, setting the stage for the all-electric Neue Klasse vehicles that will begin production later this year.

This new eDrive technology is built around an 800V architecture, enabling faster charging, increased range, and improved efficiency. The heart of this system is the Energy Master, an intelligent central control unit developed and produced by BMW. This unit manages the high- and low-voltage power supply, data from the high-voltage battery, and the power supply for the electric motor and vehicle electrical system. BMW’s in-house development of both the hardware and software for the Energy Master allows for real-time updates via Remote Software Upgrades, giving customers access to the latest advancements.

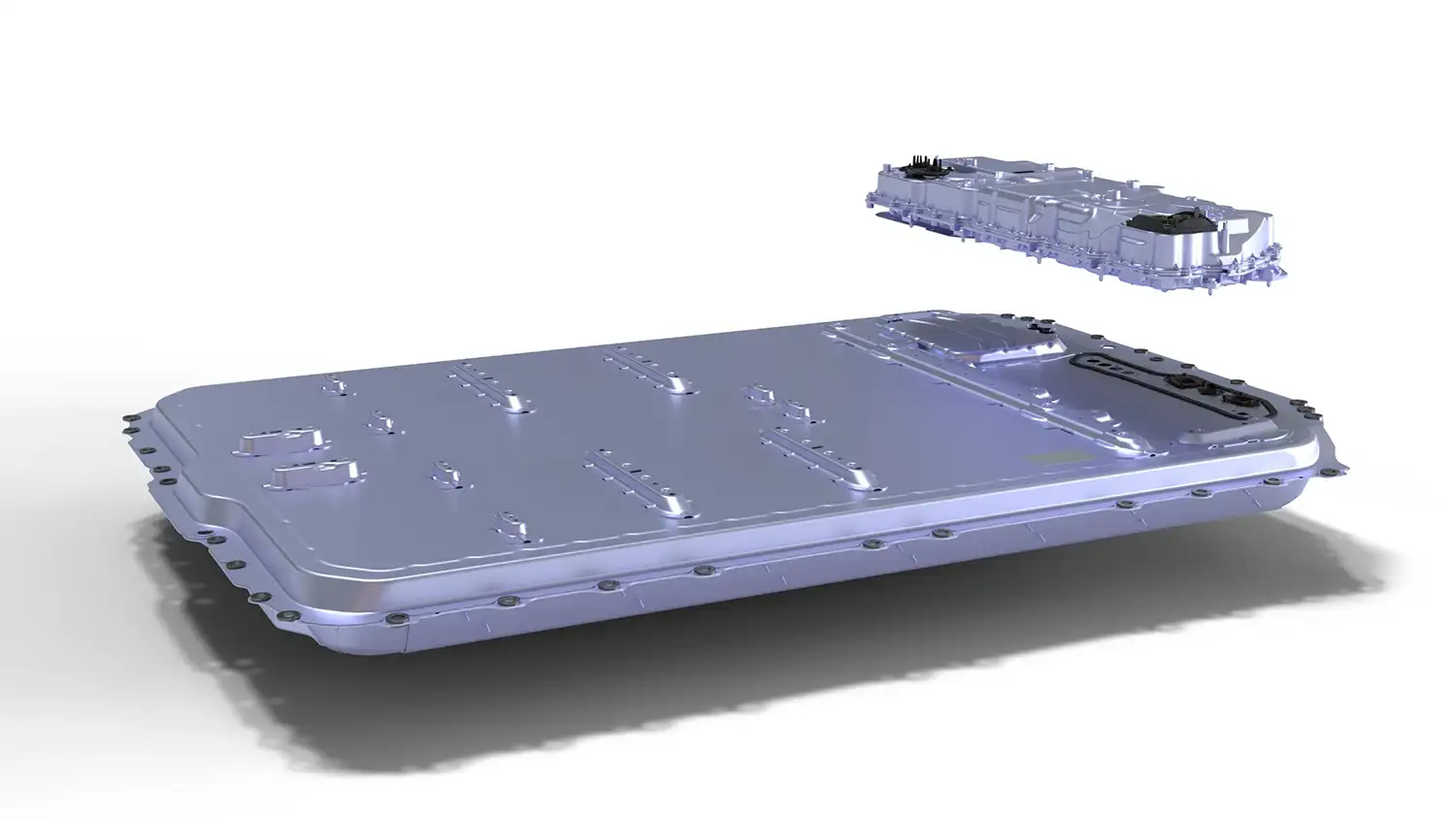

The high-voltage battery itself is a marvel of engineering. A new concept, combined with BMW’s cylindrical cell, promises significant improvements in energy density, charging speed, and range. BMW is targeting a 30% increase in both charging speed and range compared to the previous generation, with some models exceeding these figures. The battery’s slimmer design allows for integration into various models, regardless of vehicle , and it even acts as a structural component in the Neue Klasse models (“pack-to-open-body”). The cylindrical cells are integrated directly into the battery (“cell-to-pack”), boasting a 20% greater energy density than the previous generation’s prismatic cells. Adding to the convenience, bidirectional charging will be standard for Gen6.

BMW’s commitment to a technology-open approach is evident in their use of different electric motor types: SSM and ASM. This modular approach to electric motor production provides exceptional flexibility, allowing BMW to tailor the powertrain to specific vehicle needs. The company’s expertise spans the entire electric mobility value chain, from development and purchasing to production and recycling, all concentrated in Bavaria and Austria.

The “local for local” approach to high-voltage battery assembly is a key part of BMW’s strategy. Five new production facilities, located near vehicle plants in various regions, will ensure production continuity and strengthen local economies. This principle extends to the battery cell supplier network, with agreements in place with various partners for factories across Europe, China, and the USA. Production follows the “cell-to-pack” and “pack-to-open-body” principles, incorporating numerous BMW-patented innovations.

BMW is also focusing on the crucial aspect of recycling. Partnerships with companies like SK tes will ensure the recovery of valuable materials from end-of-life batteries, creating a closed-loop system. BMW is also exploring direct recycling methods to reuse materials from battery cell production.

The Gen6 eDrive system employs an electrically excited synchronous motor (EESM) for its power unit, offering excellent efficiency and constant power output. The Neue Klasse will also incorporate asynchronous motor (ASM) technology, offering a more compact and cost-efficient option. The EESM technology has been significantly upgraded, with rotor, stator, and inverter designed for the 800V architecture. The inverter, developed in-house by BMW, now features silicon carbide semiconductors for increased efficiency.

The results of these advancements are impressive. Compared to a Gen5 xDrive model, a future Neue Klasse model with EESM and ASM technology will see a 40% reduction in energy losses, a 20% reduction in costs, and a 10% reduction in weight. This translates to an overall vehicle efficiency gain of around 20% for the Neue Klasse.

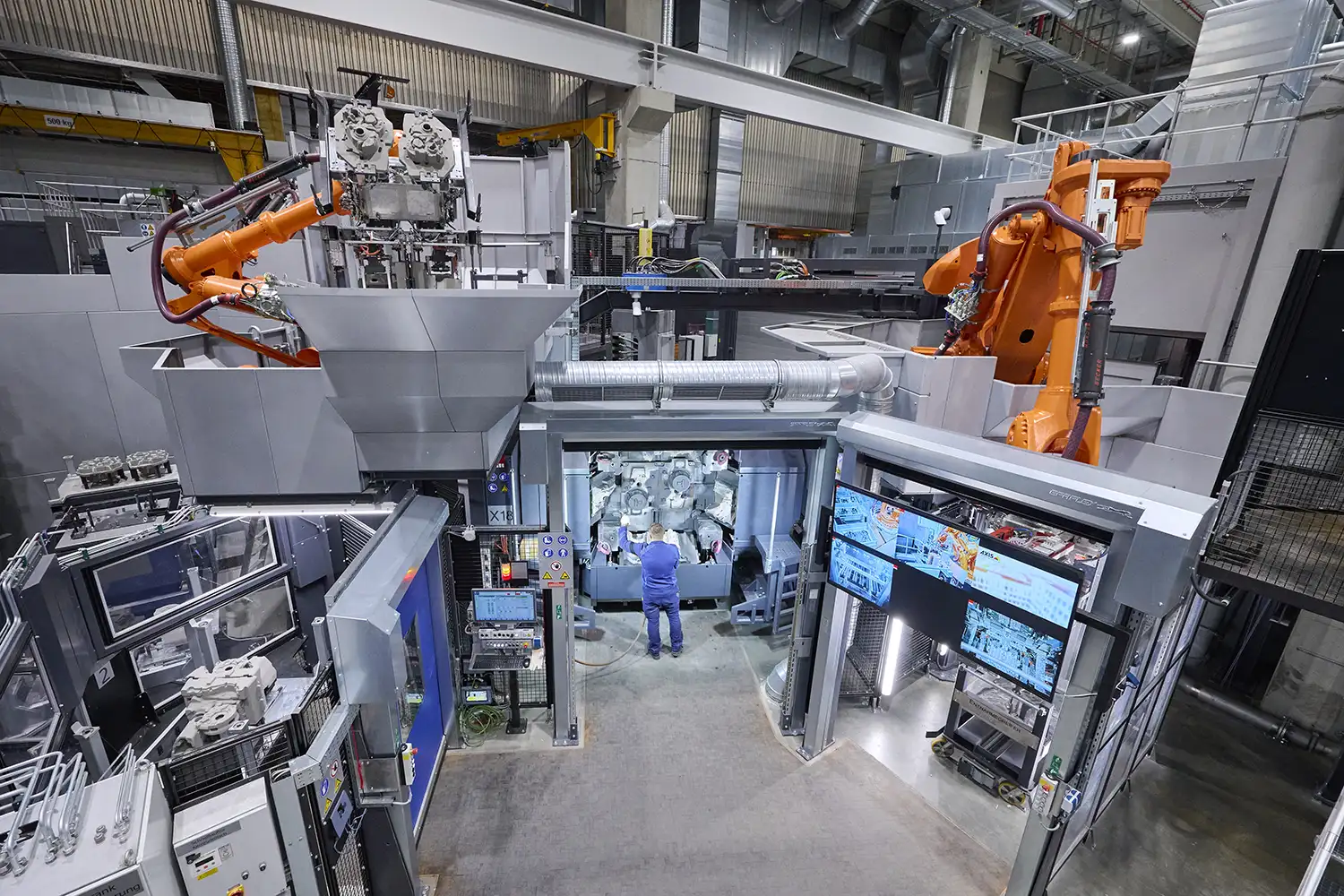

The modular concept for the Gen6 electric drive system allows for flexible manufacturing of various variants. Production will take place at BMW Plant Steyr, which has been developing and building engines for over 40 years. The plant will have an annual production capacity of 600,000 electric drive units.

Thermal management is crucial for electric vehicle performance, and BMW’s system ensures optimal temperatures for the electric motor, power electronics, and high-voltage battery. The Steyr site is responsible for developing these systems.

BMW Plant Landshut, the company’s largest component plant, plays a vital role in the Neue Klasse project, producing the Energy Master and other components. The plant is investing heavily in its light metal foundry to increase production capacity for electric motor housings.

BMW’s commitment to electric mobility is clear. With its revolutionary Gen6 eDrive technology, the company is not just preparing for the future; it’s driving it.

Summary:

- BMW unveils sixth-generation eDrive technology with 800V architecture.

- Significant improvements in charging speed, range, and efficiency.

- Intelligent Energy Master control unit developed in-house.

- New high-voltage battery concept with cylindrical cells.

- “Local for local” approach to battery assembly.

- Focus on battery recycling and sustainable practices.

- Use of both EESM and ASM motor technologies.

- Modular concept for electric drive system manufacturing.

- Thermal management system developed at Plant Steyr.

- Plant Landshut plays key role in component production.

Disclaimer: This article is for informational purposes only and does not constitute an endorsement of any specific vehicle or brand. Information regarding vehicle specifications and features may vary. Please consult with an authorized BMW dealer for the most up-to-date information.

Source: BMW

This article was crafted with assistance from Gemini