BMW is taking a bold step toward sustainable mobility with the third-generation BMW fuel cell system. Series production is set to start in 2028 at BMW Group Plant Steyr, bringing efficient hydrogen power to future vehicles. The brand is building prototypes in Munich and Steyr while key components come from Landshut, showcasing its technology-open approach.

BMW fuel cell system moves closer to production

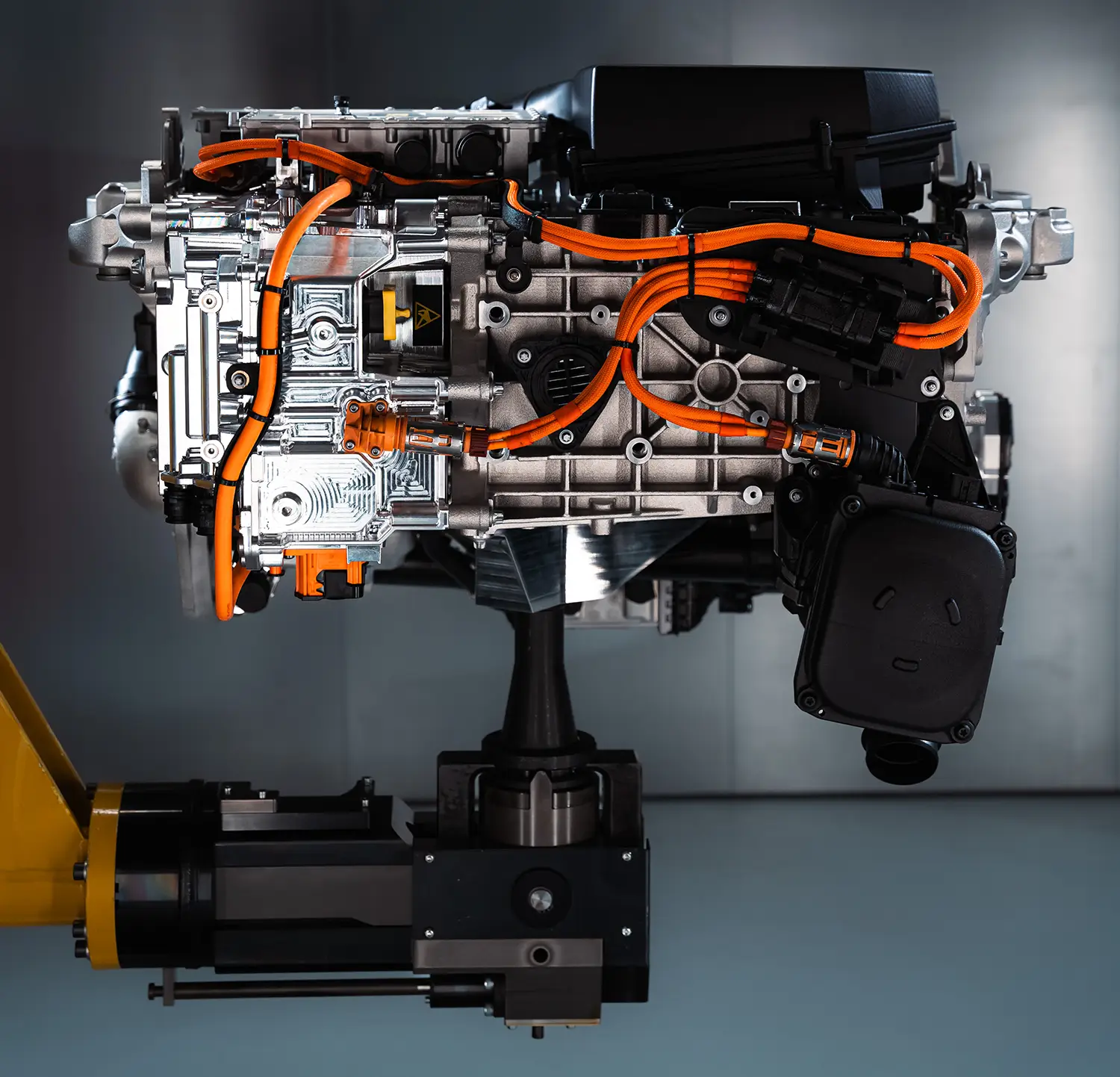

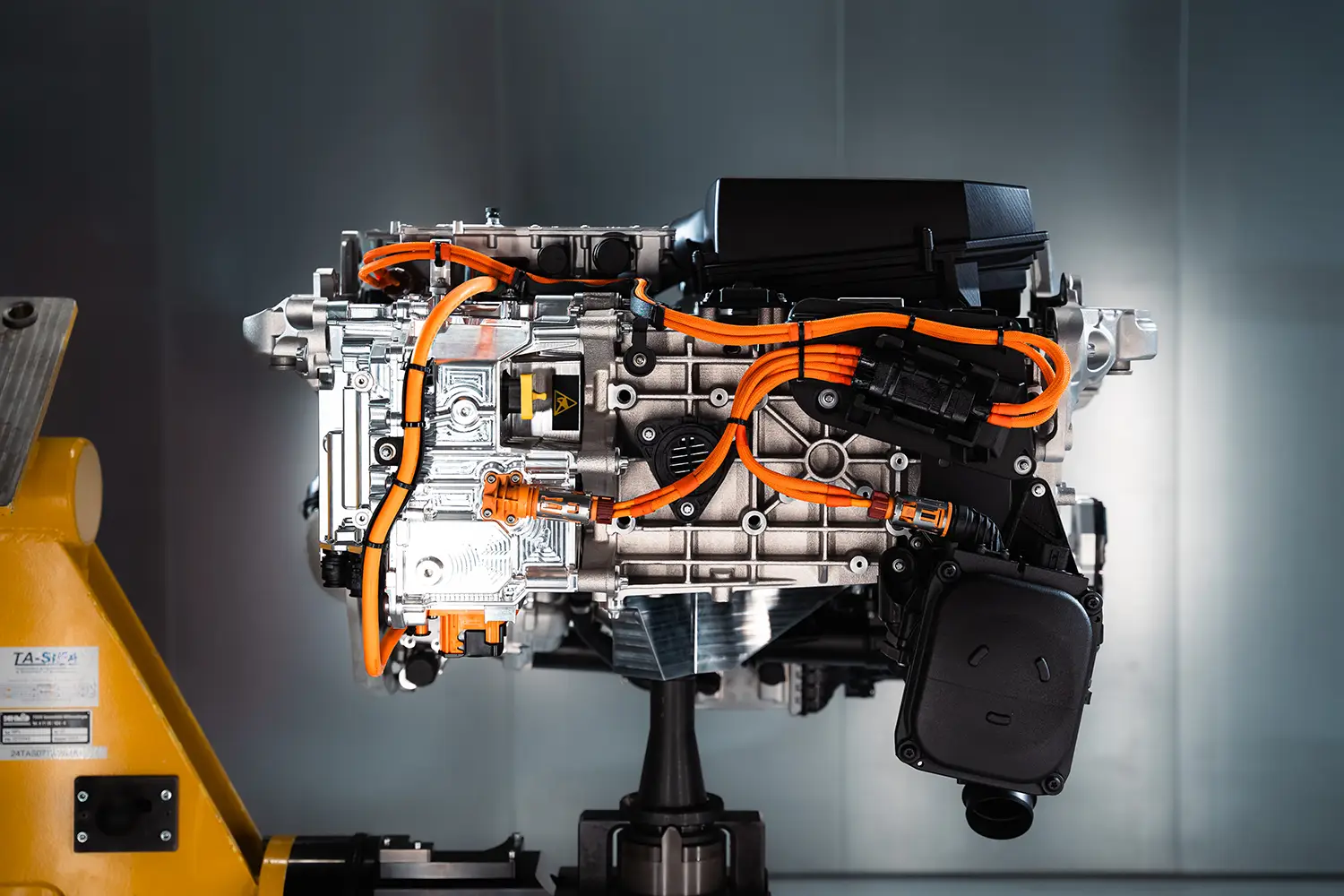

The upcoming generation of BMW’s hydrogen drive represents a leap in compact design, integration, and performance. Compared to previous models, the fuel cell system is about 25% smaller while delivering higher power density. This ensures seamless integration into various vehicle architectures and a more versatile product lineup.

Enhanced power and performance

BMW’s new fuel cell system will combine greater efficiency with increased output. Upgraded components and optimized operating strategies promise longer range and reduced energy consumption. Drivers can expect smooth, reliable power delivery from this zero-emissions drivetrain, making hydrogen a compelling option for high-performance EVs.

Munich competence hub drives innovation

At BMW’s Munich competence centre, engineers are developing prototypes and refining assembly and testing processes. The fuel cell system relies on electrochemical reactions between hydrogen and oxygen to generate electricity, powering the vehicle’s electric motor. This prototype phase ensures industrialization, quality assurance, and scalability for full-scale production.

Series production at BMW Group Plant Steyr

Production of the third-generation fuel cell systems will start in 2028 at Plant Steyr. The facility brings decades of expertise in drive system manufacturing, spanning combustion engines, electric motors, and now hydrogen technology. New production facilities and test rigs are being established to accommodate the innovative system.

Component supply from Landshut

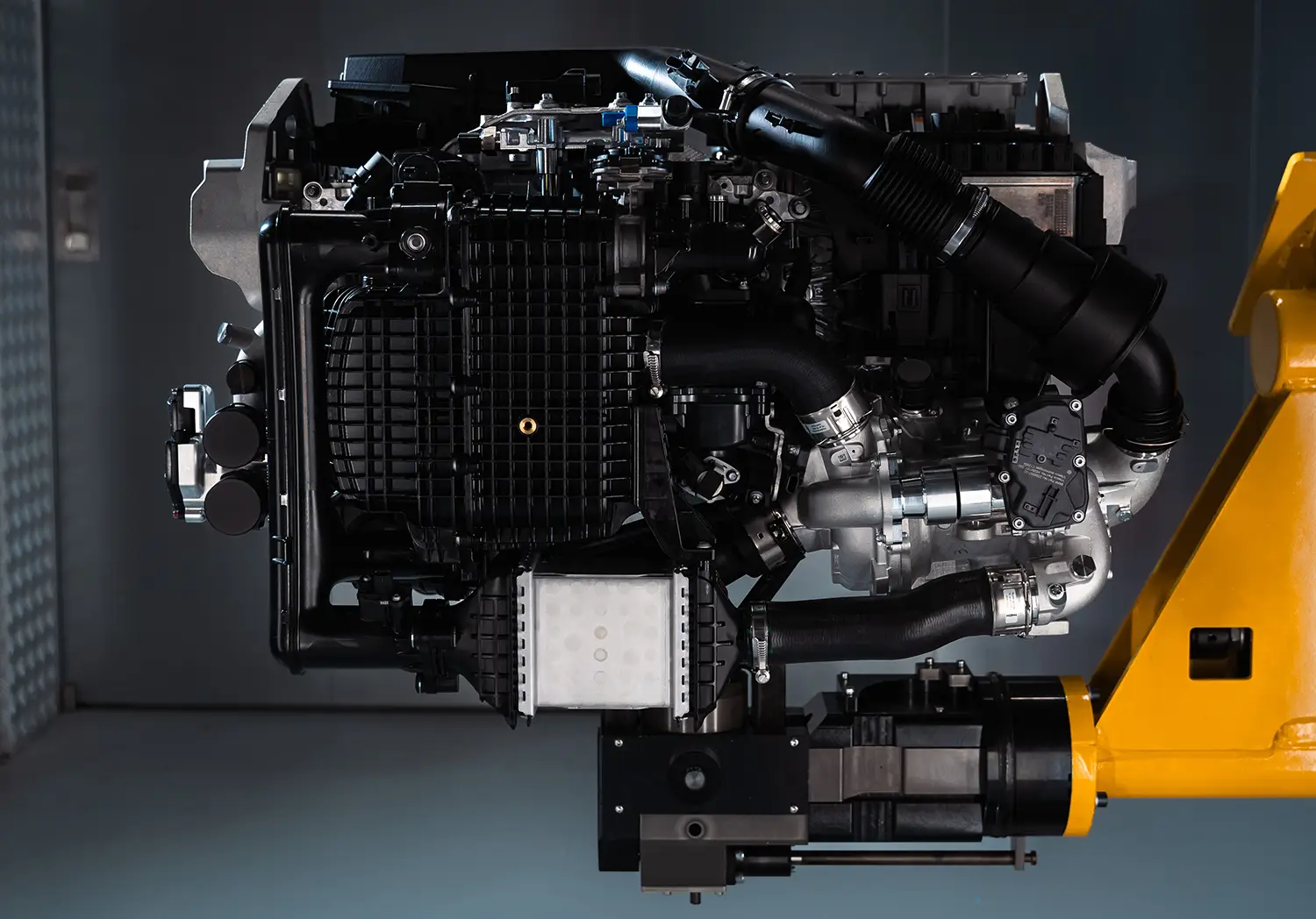

BMW Group Plant Landshut will manufacture essential components, including the hydrogen-specific Energy Master. This unit manages power supply from 400–800V and coordinates high-voltage battery data. Prototype production will begin in mid-2026 at Plant Dingolfing, paving the way for seamless series implementation.

BMW’s technology-open approach

The combination of Steyr, Munich, and Landshut facilities highlights BMW’s technology-open strategy. By leveraging in-house expertise and collaboration with Toyota, BMW is creating a high-performance, efficient fuel cell system that fits both commercial and passenger vehicle applications.

Summary

The BMW fuel cell system is poised to redefine hydrogen mobility with compact design, high power density, and enhanced efficiency. Series production in 2028 at Plant Steyr, supported by Munich and Landshut hubs, ensures BMW remains at the forefront of sustainable, high-performance drive technologies.

Disclaimer: Details about the BMW fuel cell system are based on current development and may change before series production in 2028.

Source: BMW