Audi is significantly advancing its use of Artificial Intelligence (AI) across various company sectors. The primary goals include improving efficiency, enhancing product quality, and fostering innovation. Audi aims to fully leverage the potential of AI and data. This applies to both internal company processes and the overall customer experience with services. AI is currently making the most substantial impact in production and logistics.

AI as a Transformative Force

AI brings significant advantages in manufacturing and logistics. Gerd Walker, Member of the Board of Management for Production and Logistics, highlights its critical role. He states that AI is the “game changer” in the automotive industry. Using AI strategically creates a production environment that is more efficient and cost-effective. It also ensures the highest quality standards. Furthermore, AI ideally supports human workers. Audi focuses on integrating AI wherever it makes sense, systematically expanding its applications.

Expanding Data Infrastructure

Audi actively expands its data organization, introducing new AI tools. Production generates the largest volume of data within the entire company. Hundreds of petabytes of data already exist. Thousands of gigabytes of new data are created daily. Gerd Walker explains the immense potential of this data density. Artificial intelligence allows Audi to utilize its vast data wealth more extensively in production. This accelerates the transformation of its 360factory into a data-driven factory. The 360factory represents Audi’s production strategy for fully connected and sustainable manufacturing.

Time Savings with Generative AI

Audi recently began using generative AI to analyze bids in its tendering process. The AI tool, named “Tender Toucan,” creates a list of requirements from specifications. It then searches for relevant sections in bids. The tool also evaluates how well bids meet these requirements. Employees review and finalize the tool’s work. This process results in time savings of up to 30 percent. “Tender Toucan” will launch this summer for drivetrain and high-voltage battery production planning. A broader rollout is planned for Audi and the Volkswagen Group. The development of “Tender Toucan” also provides a foundation for many other AI applications.

AI-Powered Quality Assurance

Audi employs AI-supported quality monitoring to improve overall product quality. An AI application for image processing, called “IRIS,” was recently implemented. It is used at the Ingolstadt and Neckarsulm assembly plants. This tool uses cameras to verify correct label attachment on vehicles. It checks that the label with the right content and language is on the correct component in the proper position. This process ensures vehicle conformity. Employees still perform spot checks, but the “IRIS” label check saves roughly one minute of production time per vehicle.

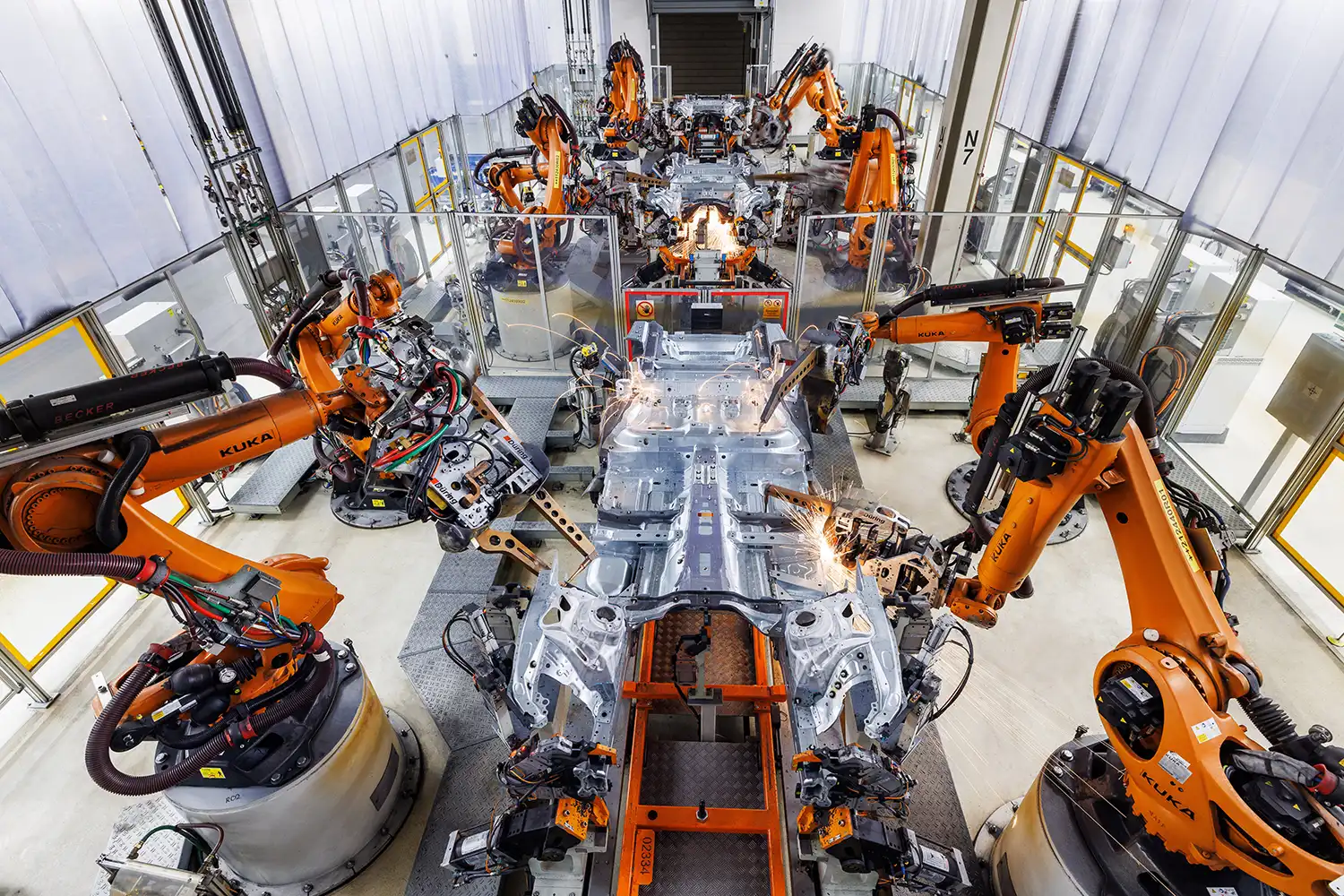

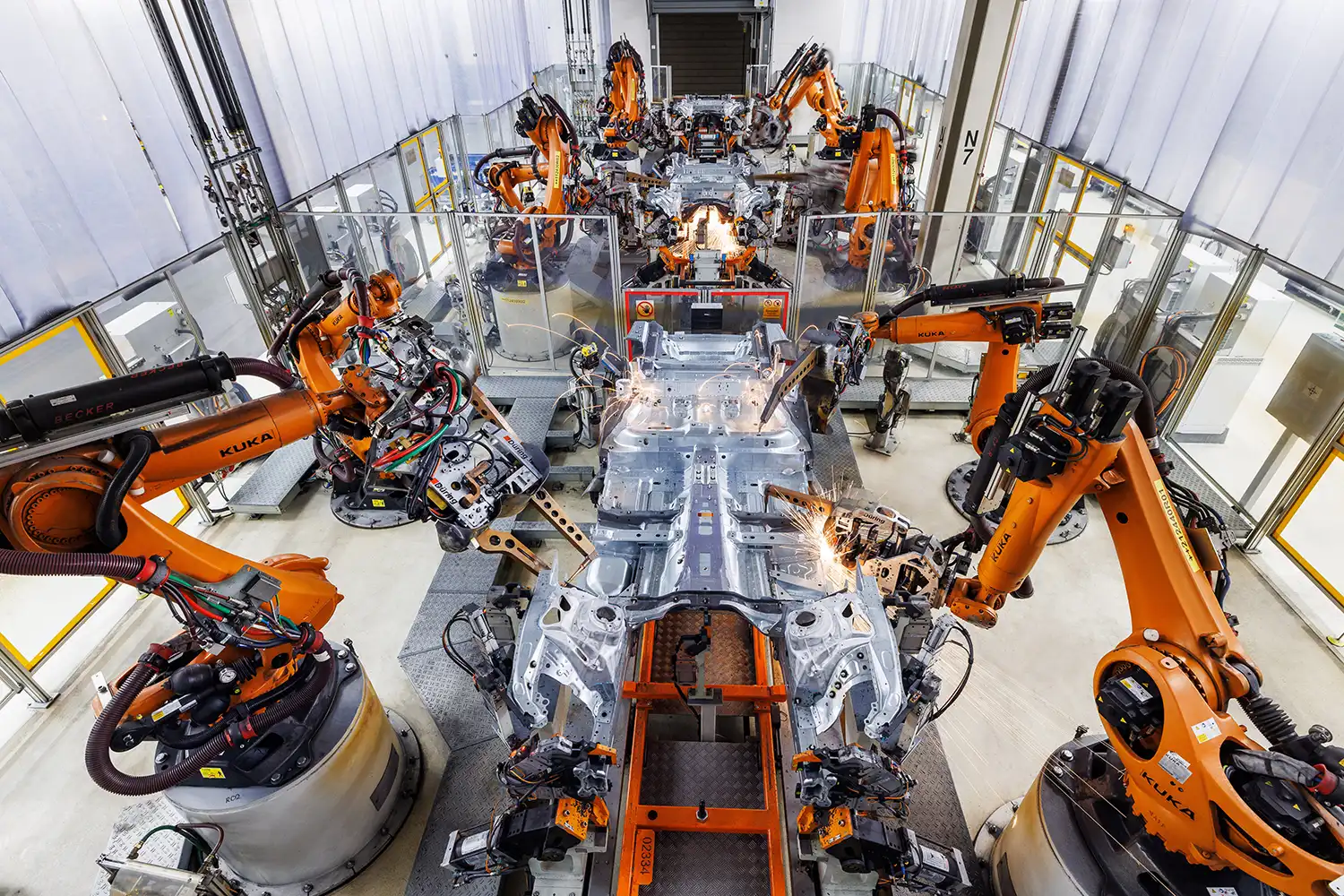

Audi also collaborated with Siemens to introduce another AI-supported quality check. This project is in series production at the Neckarsulm body shop. The “Weld Splatter Detection” (WSD) application uses AI to find weld splatter on vehicle underbodies. These small metal deposits could lead to problems, such as cable breakages. Previously, workers manually inspected and removed the splatter. In summer 2025, a robotic arm will automatically remove the weld splatter. This “WSD” AI application not only saves production time but also enhances occupational safety and ergonomics for employees.

Audi’s Robust AI Network

To maximize the benefits of Artificial Intelligence, Audi has built a strong network of experts. Audi collaborates closely with the IPAI (Innovation Park Artificial Intelligence) in Heilbronn. The IPAI aims to become Europe’s largest AI network. Construction of a 23-hectare campus will begin this year. As a member of this Heilbronn-based think tank, Audi will have its own office at the new campus. This mirrors its current presence at the IPAI site. The Audi Böllinger Höfe site is also nearby. This Audi facility for small series production acts as a real-world laboratory for digital production technologies. It is part of AI25 (Automotive Initiative 2025), an innovation network for digital transformation in the automotive industry.

Disclaimer Information provided is for general knowledge and informational purposes only, and does not constitute a warranty or representation regarding specific products, services, or future outcomes.

Source: Audi

AI Assistance: Gemini

Audi is significantly advancing its use of Artificial Intelligence (AI) across various company sectors. The primary goals include improving efficiency, enhancing product quality, and fostering innovation. Audi aims to fully leverage the potential of AI and data. This applies to both internal company processes and the overall customer experience with services. AI is currently making the most substantial impact in production and logistics.

AI as a Transformative Force

AI brings significant advantages in manufacturing and logistics. Gerd Walker, Member of the Board of Management for Production and Logistics, highlights its critical role. He states that AI is the “game changer” in the automotive industry. Using AI strategically creates a production environment that is more efficient and cost-effective. It also ensures the highest quality standards. Furthermore, AI ideally supports human workers. Audi focuses on integrating AI wherever it makes sense, systematically expanding its applications.

Expanding Data Infrastructure

Audi actively expands its data organization, introducing new AI tools. Production generates the largest volume of data within the entire company. Hundreds of petabytes of data already exist. Thousands of gigabytes of new data are created daily. Gerd Walker explains the immense potential of this data density. Artificial intelligence allows Audi to utilize its vast data wealth more extensively in production. This accelerates the transformation of its 360factory into a data-driven factory. The 360factory represents Audi’s production strategy for fully connected and sustainable manufacturing.

Time Savings with Generative AI

Audi recently began using generative AI to analyze bids in its tendering process. The AI tool, named “Tender Toucan,” creates a list of requirements from specifications. It then searches for relevant sections in bids. The tool also evaluates how well bids meet these requirements. Employees review and finalize the tool’s work. This process results in time savings of up to 30 percent. “Tender Toucan” will launch this summer for drivetrain and high-voltage battery production planning. A broader rollout is planned for Audi and the Volkswagen Group. The development of “Tender Toucan” also provides a foundation for many other AI applications.

AI-Powered Quality Assurance

Audi employs AI-supported quality monitoring to improve overall product quality. An AI application for image processing, called “IRIS,” was recently implemented. It is used at the Ingolstadt and Neckarsulm assembly plants. This tool uses cameras to verify correct label attachment on vehicles. It checks that the label with the right content and language is on the correct component in the proper position. This process ensures vehicle conformity. Employees still perform spot checks, but the “IRIS” label check saves roughly one minute of production time per vehicle.

Audi also collaborated with Siemens to introduce another AI-supported quality check. This project is in series production at the Neckarsulm body shop. The “Weld Splatter Detection” (WSD) application uses AI to find weld splatter on vehicle underbodies. These small metal deposits could lead to problems, such as cable breakages. Previously, workers manually inspected and removed the splatter. In summer 2025, a robotic arm will automatically remove the weld splatter. This “WSD” AI application not only saves production time but also enhances occupational safety and ergonomics for employees.

Audi’s Robust AI Network

To maximize the benefits of Artificial Intelligence, Audi has built a strong network of experts. Audi collaborates closely with the IPAI (Innovation Park Artificial Intelligence) in Heilbronn. The IPAI aims to become Europe’s largest AI network. Construction of a 23-hectare campus will begin this year. As a member of this Heilbronn-based think tank, Audi will have its own office at the new campus. This mirrors its current presence at the IPAI site. The Audi Böllinger Höfe site is also nearby. This Audi facility for small series production acts as a real-world laboratory for digital production technologies. It is part of AI25 (Automotive Initiative 2025), an innovation network for digital transformation in the automotive industry.

Disclaimer Information provided is for general knowledge and informational purposes only, and does not constitute a warranty or representation regarding specific products, services, or future outcomes.

Source: Audi

AI Assistance: Gemini

t=”1001″ />

t=”1001″ />