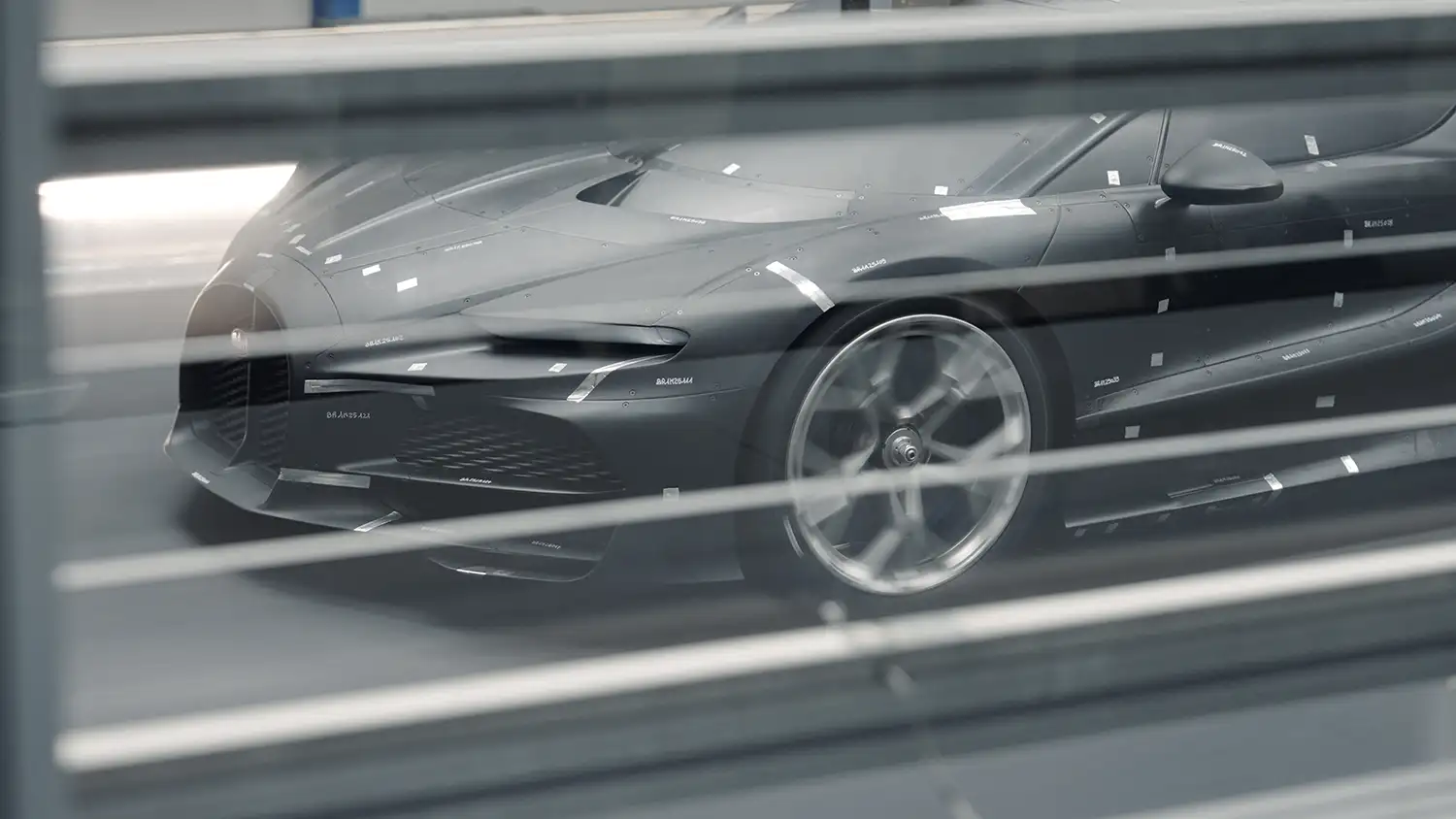

Tourbillon’s Tempest: Bugatti Redefines Hypercar Aerodynamics from Scratch Imagine a hyper sports car that doesn’t just cut through the air, but dances with it, a symphony of engineering and artistry. The Bugatti Tourbillon, revealed in June 2024, is a testament to this vision, pushing the boundaries of aerodynamic possibility. From meticulous CFD simulations to wind tunnel testing with a half-scale model, and finally, full-scale prototype validation, Bugatti’s engineers have crafted a masterpiece that transcends its predecessors.

From Concept to Reality: A Journey Through Aerodynamic Innovation The journey began with a simple yet ambitious goal: to surpass the aerodynamic achievements of the Chiron. Months of Computational Fluid Dynamics (CFD) simulations laid the groundwork, providing a virtual glimpse of the Tourbillon’s potential. Fifteen months before its public unveiling, Bugatti’s aerodynamicists convened at a state-of-the-art wind tunnel in Italy, focusing on a meticulously crafted half-scale model. This model, composed of 250 3D-printed components and equipped with over 100 pressure taps, served as the first physical validation of the Tourbillon’s design.

Data-Driven Design: Merging Insight with Expertise The extensive instrumentation on the half-scale model allowed engineers to correlate mass-flow measurements, static pressure points, and air velocities, validating their simulation-based predictions. By adjusting design elements, they steered the car towards optimal high-speed performance, later shifting focus to handling efficiency and dynamic ability. Key aerodynamic enhancements included lowering the frontal area, integrating an advanced rear diffuser, and refining the cockpit’s exterior profile.

Wind Tunnel Validation: From Model to Full-Scale Prototype As the correlation between simulation models and test results progressed, the Tourbillon evolved from a half-scale model to a full-sized prototype. This transition necessitated a shift to larger wind tunnel facilities, allowing for enhanced calibration of simulation tools and increased accuracy in results. The experimental prototype phase reaffirmed the aerodynamics teams’ simulation projections, paving the way for further prototype development and the final production vehicle.

Hybrid Complexity: A New Era of Cooling and Performance The Tourbillon’s hybrid powertrain, a significant departure from previous Bugatti models, introduced new complexities to the cooling system. Teams meticulously analyzed airflows through radiator channels and intakes, ensuring digital simulations aligned with physical models to manage the car’s performance. The dedication to detail and the pursuit of perfection defined the Tourbillon’s development, with every team member committed to establishing a new benchmark for the automotive industry.

Performance Without Compromise: Achieving Top Speed Without Deployed Wing The culmination of years of passionate craftsmanship, the Tourbillon’s aerodynamic design allows it to achieve its top speed without deploying the rear wing, maintaining exceptional stability. This feat underscores the dedication and skill poured into the project, taking Bugatti hyper sports car capabilities to unprecedented s.

Summary:

- Bugatti Tourbillon focuses on advanced aerodynamic design.

- Development included CFD simulations, half-scale model wind tunnel tests, and full-scale prototype validation.

- Meticulous data collection and analysis were used to refine the car’s design.

- Hybrid powertrain introduced complexities to the cooling system.

- Tourbillon can achieve top speed without deploying the rear wing.

*Disclaimer: The information provided is based on Bugatti’s official releases. Performance and specifications are subject to change. Always refer to official Bugatti sources for the latest details.

Source: Bugatti

This article was crafted with assistance from Gemini