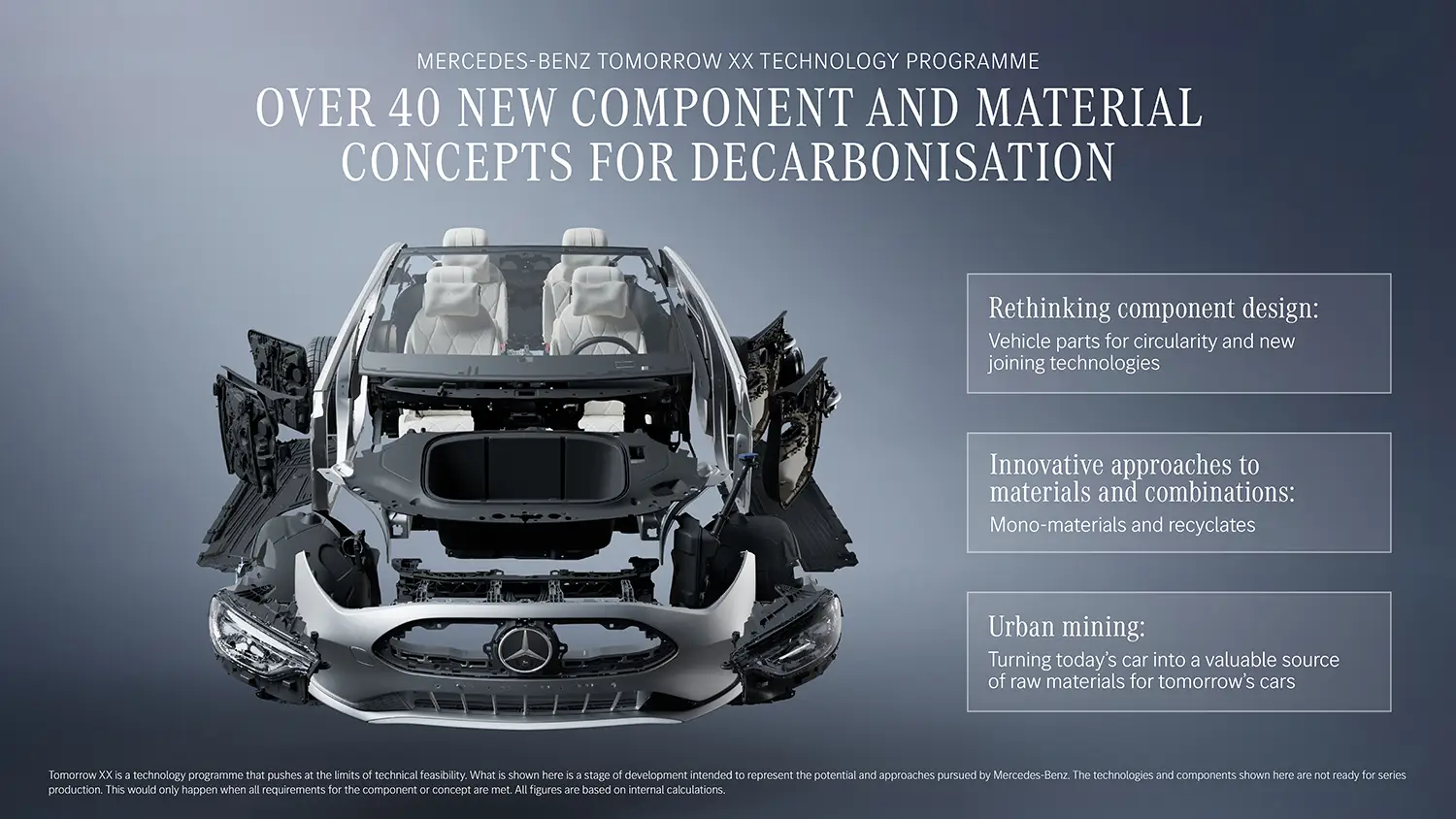

The new Mercedes-Benz Tomorrow XX technology program represents a dynamic, far-reaching commitment to sustainability across the entire vehicle product portfolio. Leveraging the successful holistic approach of the VISION EQXX, this initiative extends its focus on decarbonization and resource circularity from the very start of the design process. Mercedes-Benz development experts work closely with partners, including recycling companies and startups. Their collective goal is to scrutinize every material from the battery to the interior components.

The Core Pillars of Tomorrow XX Strategy

The program operates under the principles of “Design for Environment” and “Design for Circularity.” These approaches aim to reduce the carbon footprint and minimize the consumption of finite resources. The long-term goal is to close material loops completely. Over 40 new components and material concepts have already been identified in just two years. These innovations demonstrate enormous potential to substantially increase recycled content and significantly reduce a future vehicle’s carbon footprint.

Rethinking Component Design for Separation

Mercedes-Benz is actively tackling the challenge of recycling complex, multi-material components. The goal is to make these parts easy to dismantle and separate by material type. Mono-materials are highly favored because they simplify recycling immensely. Conversely, mixed materials are far more difficult to process economically.

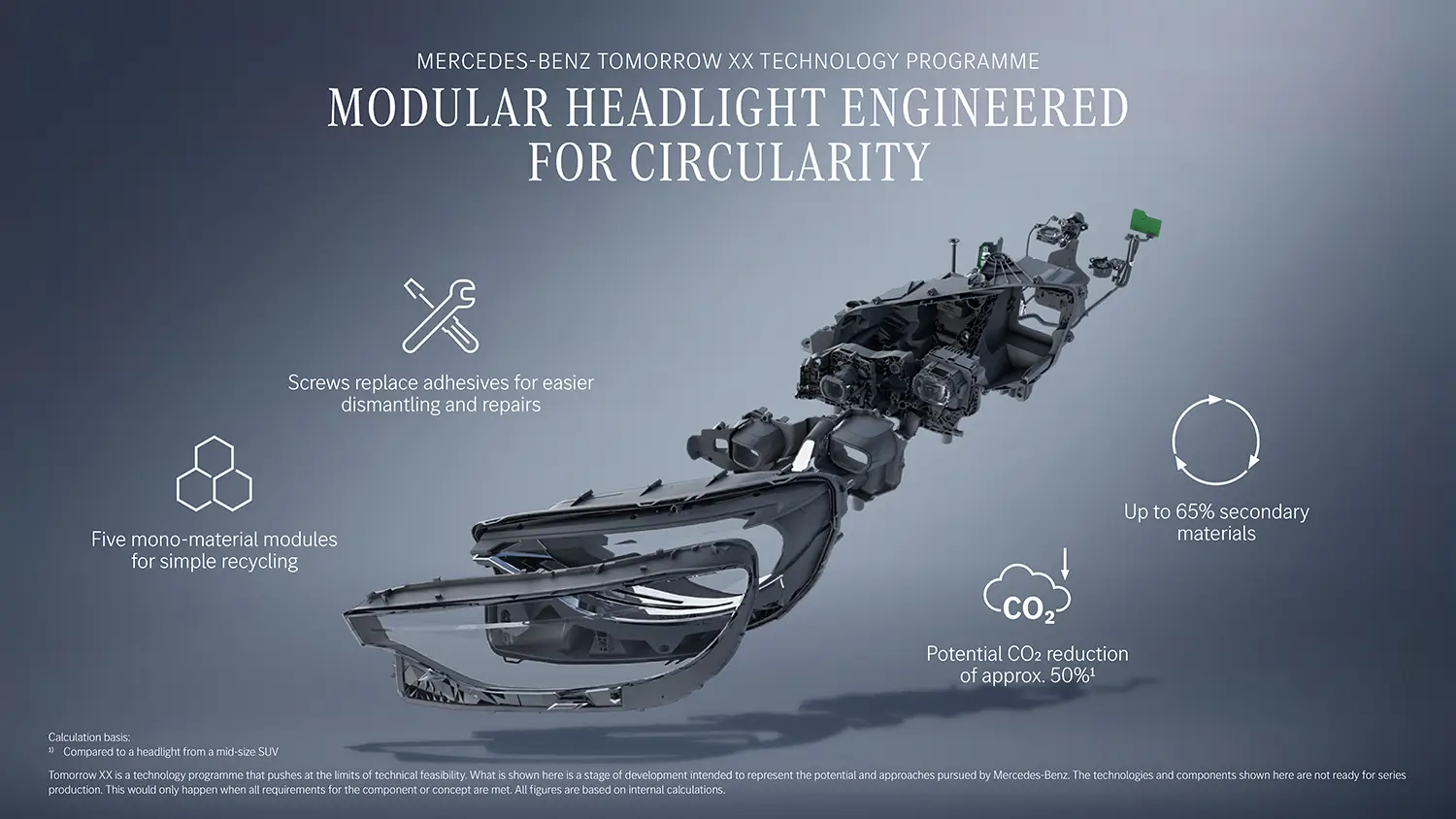

Making the Inseparable Separable: Headlights and Door Panels

A promising research project involves a recyclable headlight. Today, headlights are typically joined with glue, making them non-repairable and difficult to recycle. The new concept uses fasteners instead of adhesives to join the lens, cover, and frame. This innovation allows the headlight to be easily separated into individual components. As a result, components like a stone-chipped lens could be replaced individually, improving repair efficiency and conserving resources. The mono-material design of individual modules aims to almost double the proportion of secondary materials used.

Innovative Joining Technology

Similarly, interior door panels, which often consist of different parts joined by ultrasonic welding, are being redesigned. Mercedes-Benz has developed a new joining technology using an adapted thermoplastic rivet. This rivet is easy to undo, allowing faster separation of individual components without damage. This optimization simplifies repairs and greatly improves recyclability.

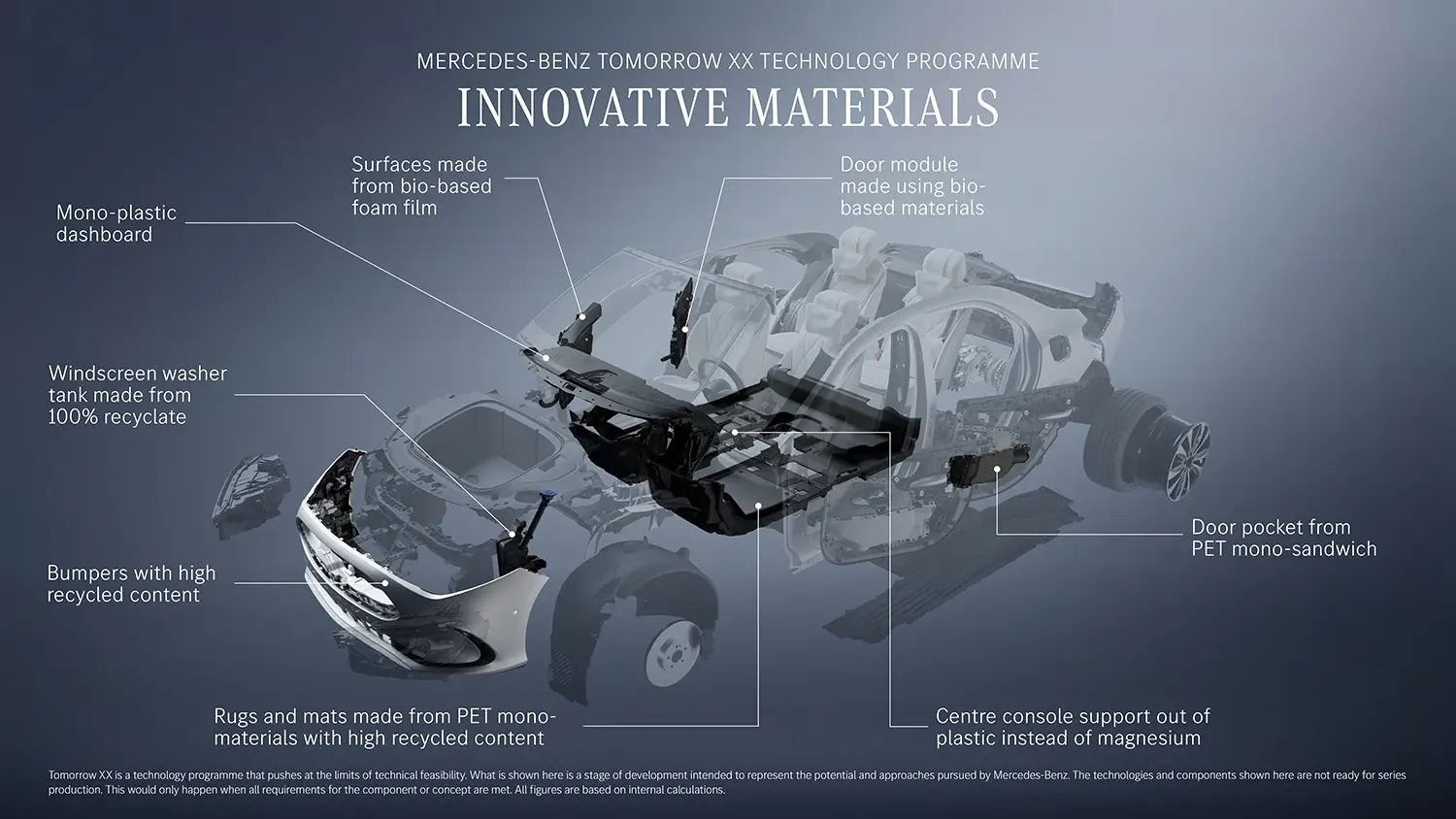

Accelerating the Use of Secondary Materials

A modern Mercedes-Benz vehicle contains approximately 550 pounds of plastic. The Tomorrow XX program focuses heavily on replacing primary resources with secondary materials, especially mono-materials. An innovative PET mono-sandwich composite has been developed for interior components like door pockets. This system consists solely of recycled PET, reducing the door pocket’s weight by over 40 percent. It recently won the international Materialica Award.

High-Content Recycled Aluminum and Steel

Aluminum production is energy-intensive, so the program promotes the use of intelligent, low-carbon solutions. One highlight is an aluminum side wall containing up to 86 percent post-consumer scrap. Furthermore, 40 percent of the aluminum for the new CLA is already produced using renewable energy. For steel, the company is targeting almost zero-carbon production by replacing the traditional blast-furnace process with hydrogen-based direct reduction. Mercedes-Benz is already using series production steel products with a 100 percent scrap content, reducing the CO2 footprint by over 60 percent.

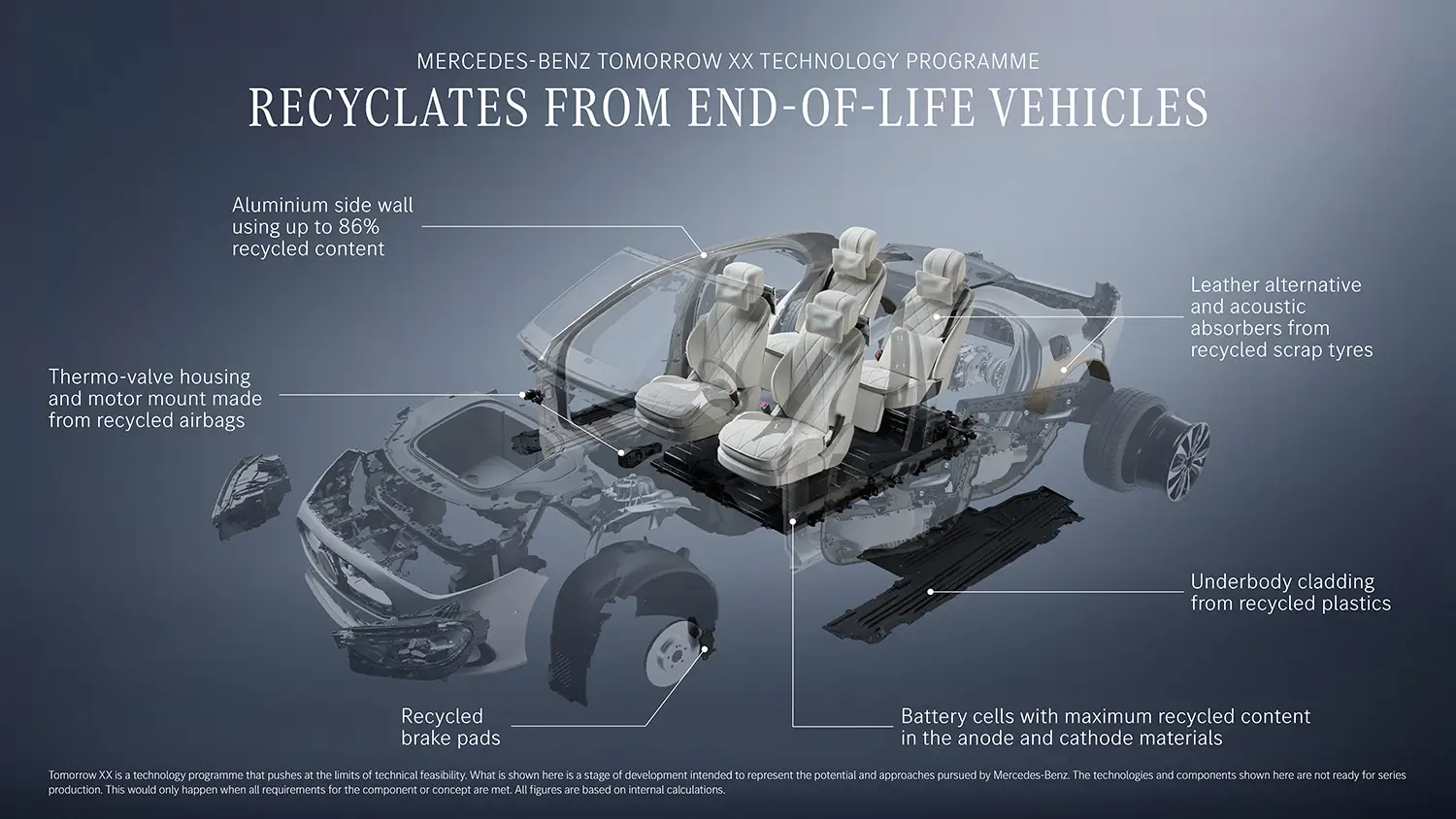

Urban Mining and Closing the Material Loop

Mercedes-Benz views vehicles at the end of their lifecycle as a strategic source of raw materials, a concept known as urban mining. A pilot project for an innovative scrap vehicle collection site is underway in northwestern Germany. This provides crucial insights for scaling up the integration of post-consumer materials. The company is actively working to replace existing materials with post-consumer recyclates from scrap vehicles.

New Life for Old Tires and Airbags

Scrap tires are chemically recycled into pyrolysis oil, which is then processed with certified biomethane into plastic (mass balance method). This innovative recycled plastic is already used in components like a flush-fitting door handle. Used tires are also mechanically recycled into acoustic insulation fibers for NVH measures. Similarly, high-quality airbag material (fiberglass-reinforced polyamide) is being recycled to create new high-tech components. These include engine mounts and valve housings.

Decarbonizing the Battery Value Chain

The battery has the highest carbon footprint in an electric vehicle. Mercedes-Benz is pursuing a multi-stage approach to decarbonization. This includes contracting cell manufacturers who commit to using green electricity in production. Furthermore, the brand is researching dry coating as a forward-looking technology for electrode production. This process replaces energy-intensive drying and eliminates environmentally sensitive additives.

Battery System Design for Circularity

The innovative battery system of the new MMA platform incorporates “Design for Circularity” aspects. Components are designed to be easily disassembled without using non-separable joining techniques or composite materials. Using materials like steel, which have existing circular economies, helps to significantly reduce the overall carbon footprint of the battery housing and modules.

Performance Specifications and Innovative Material Combinations

The Tomorrow XX program continues to find innovative material substitutions. The new center console support, which must withstand high collision forces, is now being developed using glass fiber-reinforced polypropylene with steel inserts. This combination could reduce the carbon footprint of this part by over 90 percent. Furthermore, the use of BIONICAST® technology, first seen in the VISION EQXX, delivers up to a 25 percent savings in weight and material by ensuring material is used only where structurally necessary.

Summary of Tomorrow XX’s Impact

The Mercedes-Benz Tomorrow XX program is pushing the limits of technical achievement to embed sustainability into every vehicle component. By focusing on circularity, replacing primary materials with high-content secondary resources, and decarbonizing the supply chain, Mercedes-Benz is laying the groundwork for a truly resource-efficient automotive future. The more than 40 concepts already identified show enormous potential to change the industry’s approach to vehicle production.

Disclaimer: Content on this site is for informational and entertainment purposes only. Details, analyses, and opinions reflect current trends and personal views, not professional or financial advice. Always verify information with official sources before making any decisions.

Source: Mercedes-Benz