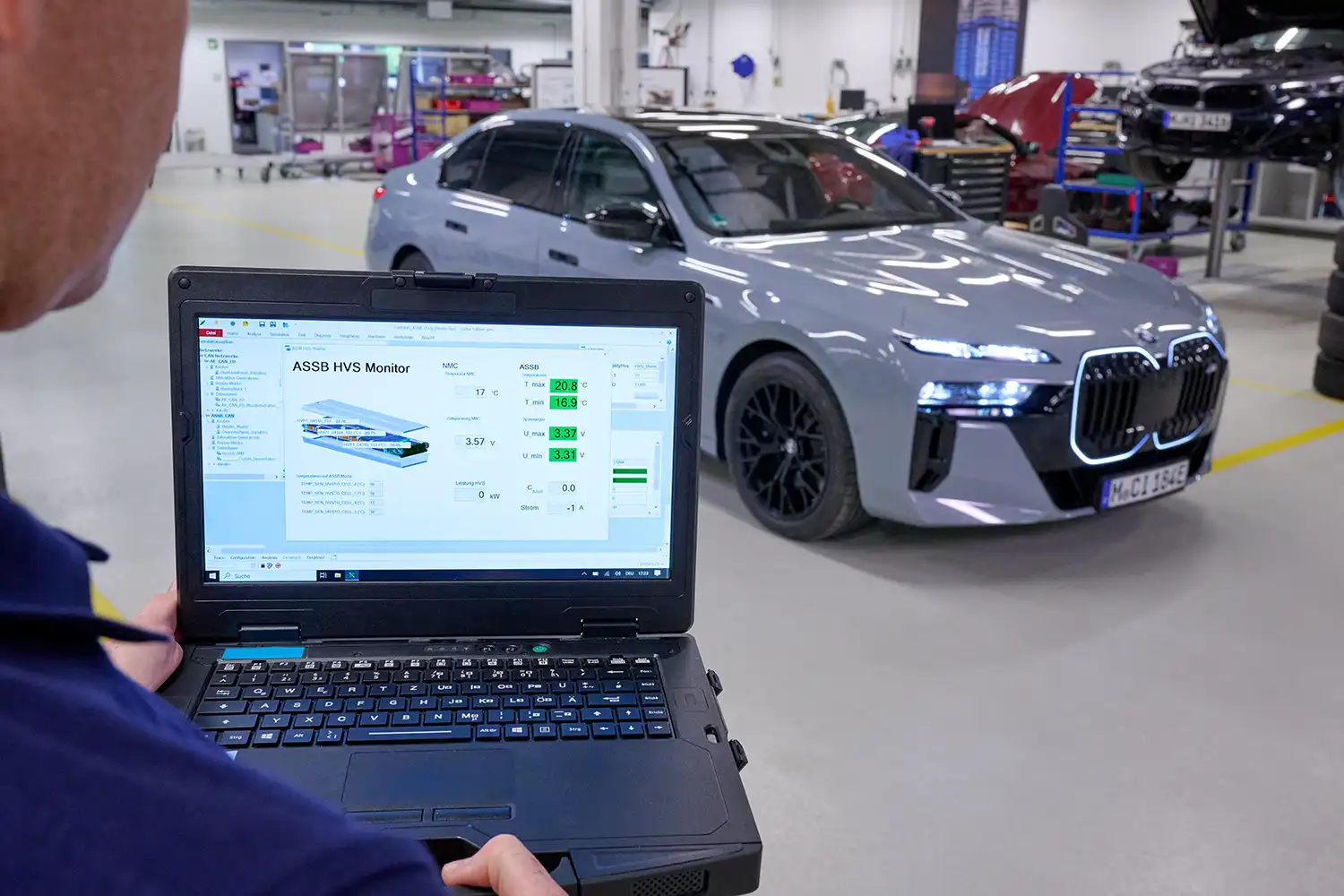

The BMW Group is marking a significant stride in electric vehicle technology by actively testing large-format, pure all-solid-state battery (ASSB) cells from Solid Power in a BMW i7 test vehicle. This pioneering integration, taking place in the Munich area, underscores the potential of ASSB technology to deliver higher energy density within a very compact storage system compared to existing battery solutions. This development is a direct result of the intensified collaboration between the BMW Group and Solid Power, Inc., a partnership that has been deepening since 2022 through a dedicated technology transfer agreement.

Partnership Milestones: The cooperation between the BMW Group and Solid Power dates back to 2016 with an extended “Joint Development Agreement”. This strategic alliance was further solidified by the BMW Group’s investment in Solid Power in May 2021 as part of a financing round. At the close of 2022, both entities further deepened their partnership, with BMW agreeing to operate a solid cell prototype line at its Cell Manufacturing Competence Center (CMCC) in Parsdorf. This initiative leverages a research and development license, incorporating the valuable experience and expertise of Solid Power.

Powertrain and Performance Potential: The core benefit of all-solid-state battery technology, as highlighted by both BMW Group and Solid Power, is its potential for a higher energy density compared to current battery technologies. This improved energy density holds the promise of achieving longer ranges for electric vehicles without introducing the disadvantage of increased weight in the overall storage system. John Van Scoter, President and Chief Executive Officer of Solid Power, expressed immense pride in this partnership, noting its successful demonstration of truly all-solid-state battery cells in a vehicle for the first time. He emphasized Solid Power’s ongoing commitment to innovating their sulfide electrolyte in support of the future of electric vehicles.

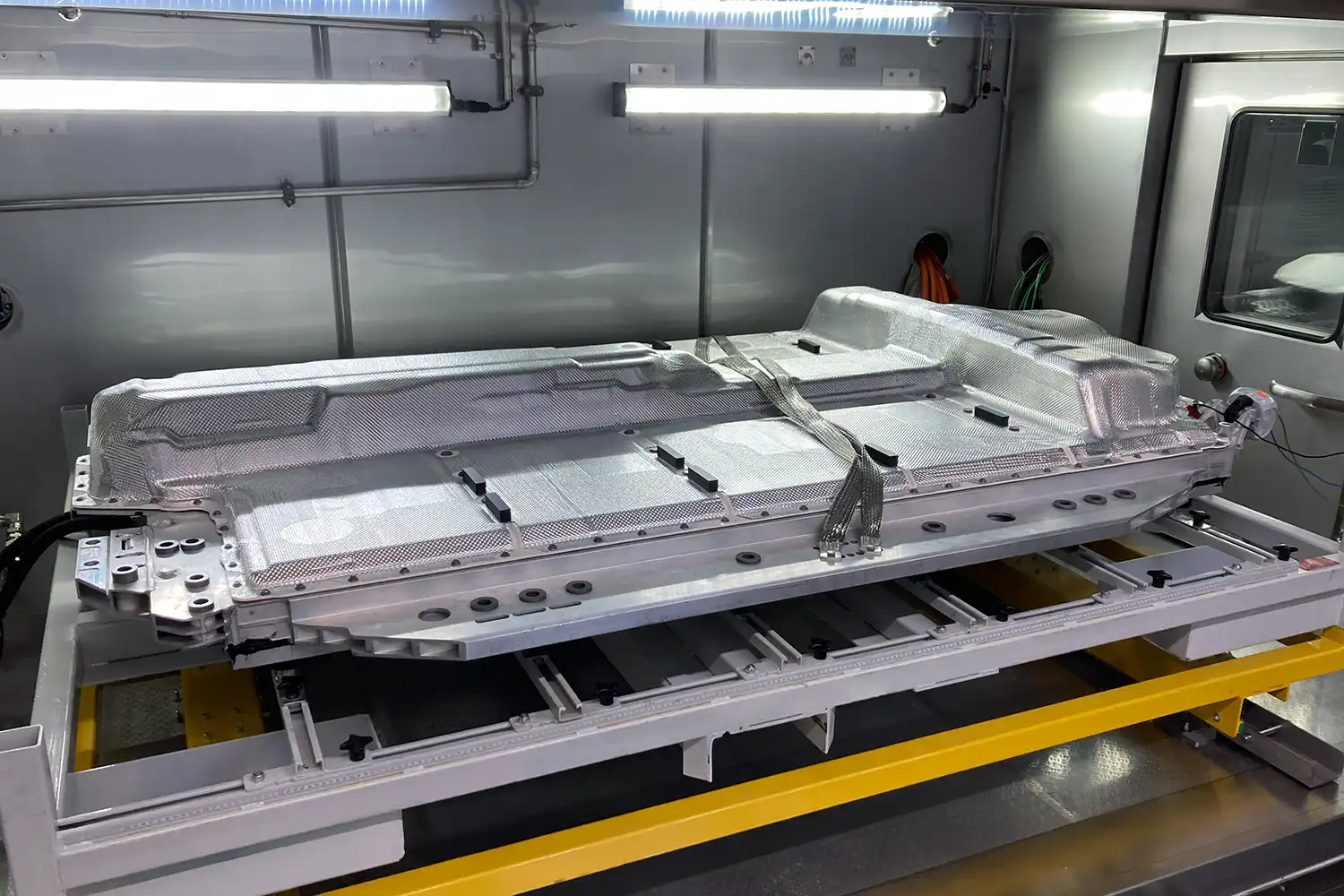

Technological Integration and Testing: The innovative cells, which were developed and manufactured jointly by Solid Power and BMW Group experts, are integrated into the BMW i7 test vehicle using a concept battery. This concept battery combines proven Gen5 construction principles, which involve prismatic cells within modules, with new, innovative module concepts specifically designed for integrating the ASSB cells from Solid Power. Key areas of investigation within this test program include the management of cell expansion, the control of operating pressure, and the adjustment of temperature conditions. The use of Solid Power cells with sulfide-based electrolytes and their complete integration into a battery pack will yield further crucial findings for the BMW Group over the coming months.

BMW’s Battery Strategy: Martin Schuster, Vice President Battery Cell and Cell Module at the BMW Group, underscored the company’s technology-open mindset, citing the BMW i7 ASSB test vehicle as a perfect example. He affirmed the BMW Group’s continuous advancement in developing new battery cell technologies and its ongoing expansion of know-how through collaborations with valuable partners like Solid Power. Since 2008, the BMW Group has systematically built its expertise in battery cell technology, consolidating this knowledge at its Battery Cell Competence Center (BCCC) in Munich since 2019. The BCCC encompasses the entire value chain, from research and development to battery cell design and production capability. To efficiently implement battery cell technology innovations, the BMW Group maintains a collaborative network of approximately 300 partners, including established companies, startups, and universities. This collaboration with Solid Power specifically highlights the BMW Group’s battery strategy: to jointly develop innovative battery technologies with leading industry partners, ensuring access to cutting-edge global battery cell research. Further development steps are still required to implement ASSB technology into a competitive overall storage system.

Summary

- BMW Group and Solid Power are testing all-solid-state battery (ASSB) cells in a BMW i7.

- ASSB technology aims for higher energy density and longer ranges without added weight.

- Partnership intensified since 2022, with cooperation dating back to 2016 and BMW’s investment in 2021.

- BMW operates a solid cell prototype line at its CMCC in Parsdorf.

- The test vehicle integrates Solid Power cells with existing Gen5 construction principles.

- Investigations focus on cell expansion, operating pressure, and temperature control.

- BMW’s Battery Cell Competence Center (BCCC) leads internal expertise and collaborates with partners.

Disclaimer: This article is based on information from a press release and is intended for general informational purposes. Technical specifications and progress are subject to ongoing development and research. Specific details may evolve.

Source: BMW

AI Assistance: Gemini