Four Decades of Innovation: McLaren’s Unrivaled Pedigree in Carbon Fiber Engineering: McLaren’s expertise in lightweight engineering, rooted in carbon fiber chassis technology, spans over 40 years, establishing an unparalleled legacy in composite engineering. From revolutionizing Formula 1 to underpinning every McLaren road car, carbon fiber monocoques represent the ultimate ‘race track-to-road’ innovation. The new W1 hypercar is the latest expression of McLaren’s unmatched capabilities, showcasing the Aerocell carbon monocoque and debuting McLaren ART carbon fiber.

Pioneering Formula 1 Technology: The MP4/1 and the Carbon Fiber Revolution: In 1981, the McLaren MP4/1 revolutionized Formula 1 as the first race car to utilize a full carbon fiber monocoque chassis. Designed by John Barnard, this lightweight and rigid structure significantly improved both safety and performance, leading to widespread carbon fiber adoption in motorsport. John Watson’s unharmed escape from a 140mph crash at the 1981 Italian Grand Prix solidified carbon fiber’s safety benefits, while his subsequent British Grand Prix victory showcased its performance potential.

The McLaren F1: Setting the Standard for Road Car Carbon Fiber: The 1993 McLaren F1, with its carbon fiber monocoque chassis and full carbon fiber body, pioneered the use of carbon fiber in road cars. Its light weight of 1,140kg and 627PS V12 engine delivered unmatched performance. The F1’s carbon fiber monocoque, engineered with cutting-edge computer-aided design, achieved an unprecedented power-to-weight ratio, cementing its status as a supercar icon. The F1 also demonstrated carbon fiber’s versatility by winning the 1995 Le Mans 24 Hours.

The McLaren 12C: Mass-Producing Carbon Fiber Supercars: In 2011, the McLaren 12C introduced the MonoCell, a single-piece carbon fiber tub that provided unprecedented stiffness and lightness. This marked the beginning of McLaren’s mass-produced full carbon fiber tub supercar range, bringing the benefits of carbon fiber to a wider audience. The MonoCell’s torsional rigidity allowed the 12C Spider to forgo additional chassis strengthening, a hallmark of McLaren’s convertible designs.

The McLaren P1™: Electrification and Carbon Fiber Integration: The 2013 McLaren P1™ further advanced carbon fiber technology with its MonoCage structure, incorporating the roof, lower structures, and even the battery and power electronics housing. This 90kg structure demonstrated that electrification could coexist with lightweight design, proving that hybrid supercars could achieve exceptional performance without compromising weight.

The McLaren 720S: Enhancing Rigidity and Ergonomics: The 2017 McLaren 720S introduced the Monocage II, enhancing rigidity and reducing weight compared to its predecessor. This structure, still used in the 750S, improved ergonomics, visibility, and design. The slim roof pillars and rearward B-pillars created a spacious cabin, while the drop-down sills and dihedral doors improved ingress and egress. The 720S Spider’s bespoke carbon fiber upper rear structure eliminated the need for additional strengthening.

The McLaren Composites Technology Centre: Advancing Carbon Fiber Production: The 2018 opening of the McLaren Composites Technology Centre (MCTC) in Sheffield marked a £50 million investment in carbon fiber production. This facility, a partnership between McLaren Automotive, the University of Sheffield’s AMRC, and Sheffield City Council, aims to be a center of excellence in composites engineering and production. The MCTC produced carbon fiber parts for the McLaren 765LT, including its active rear wing and bumper.

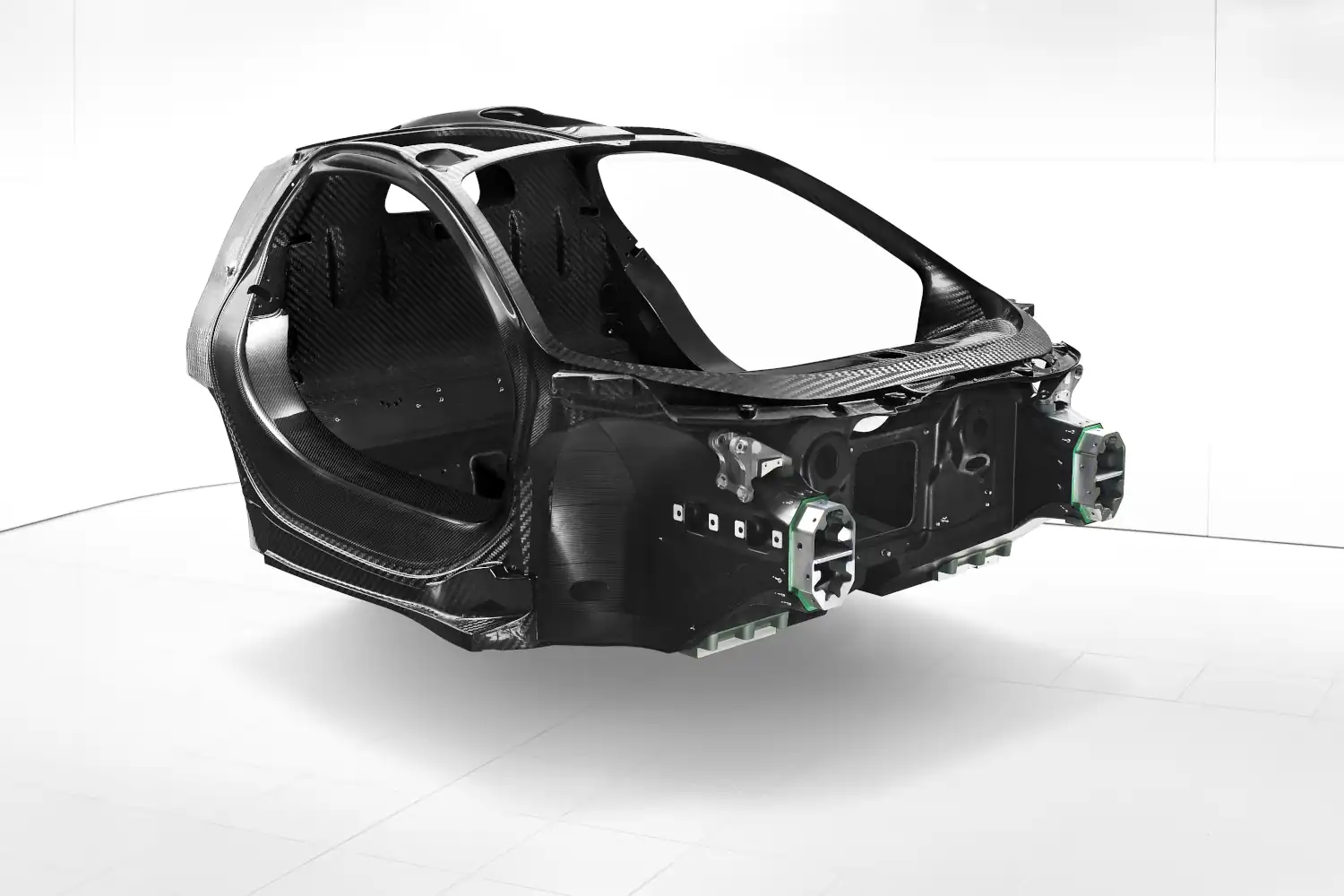

The McLaren Artura: Hybrid Powertrains and Carbon Fiber Architecture: The 2021 McLaren Artura introduced the McLaren Carbon Lightweight Architecture (MCLA), designed for high-performance hybrid powertrains. The MCLA, manufactured at the MCTC, is lighter and stronger than previous chassis, integrating a safety cell for the hybrid system’s battery. The Artura’s MCLA also enabled production in volumes never before achievable, and the Artura Spider maintained the lightweight spider DNA without additional chassis strengthening.

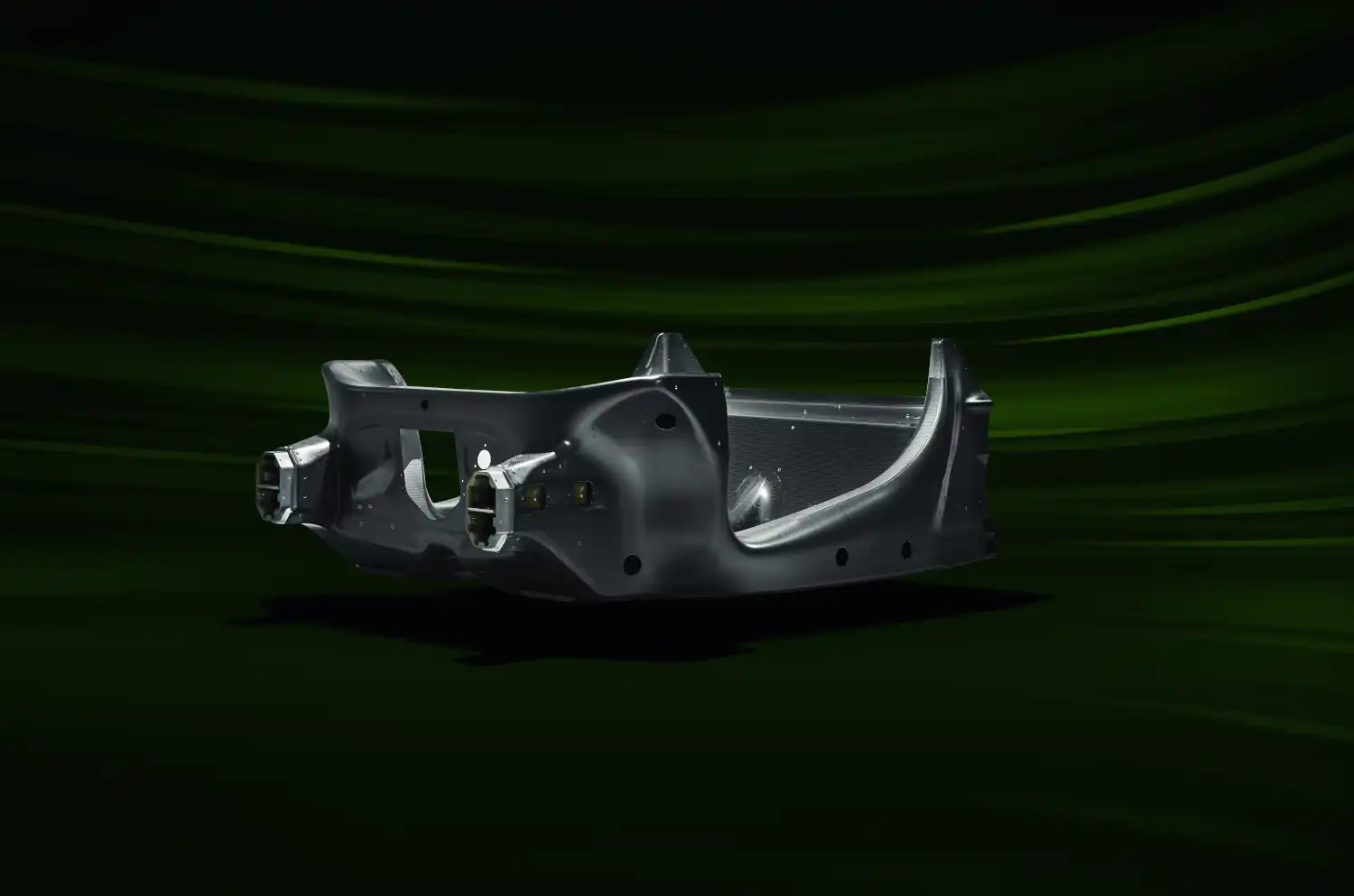

The McLaren W1: Aerocell and McLaren ART Carbon Fiber: The 2024 McLaren W1 features the Aerocell, McLaren’s most advanced carbon fiber tub, using pre-preg carbon fiber and pressure treatment for higher structural strength. The Aerocell’s design optimizes ground effect and ergonomics, with a raised floor and integrated seating. The W1 also debuts McLaren ART carbon fiber, made possible by the Automated Rapid Tape (ART) manufacturing technique, offering lighter, stiffer, and more sustainable carbon fiber parts.

Summary:

- McLaren’s 40+ year carbon fiber legacy.

- MP4/1: First F1 carbon fiber monocoque.

- McLaren F1: Pioneering road car carbon fiber.

- 12C: Mass-produced carbon fiber supercars.

- P1™: Electrification and carbon fiber integration.

- 720S: Enhanced rigidity and ergonomics.

- MCTC: Advancing carbon fiber production.

- Artura: Hybrid powertrains and MCLA.

- W1: Aerocell and McLaren ART carbon fiber.

Disclaimer: Vehicle specifications and technological advancements are based on information provided by McLaren Automotive. Actual performance and features may vary. Prospective buyers are encouraged to consult with McLaren representatives for detailed information.

Source: McLaren

This article was crafted with assistance from Gemini