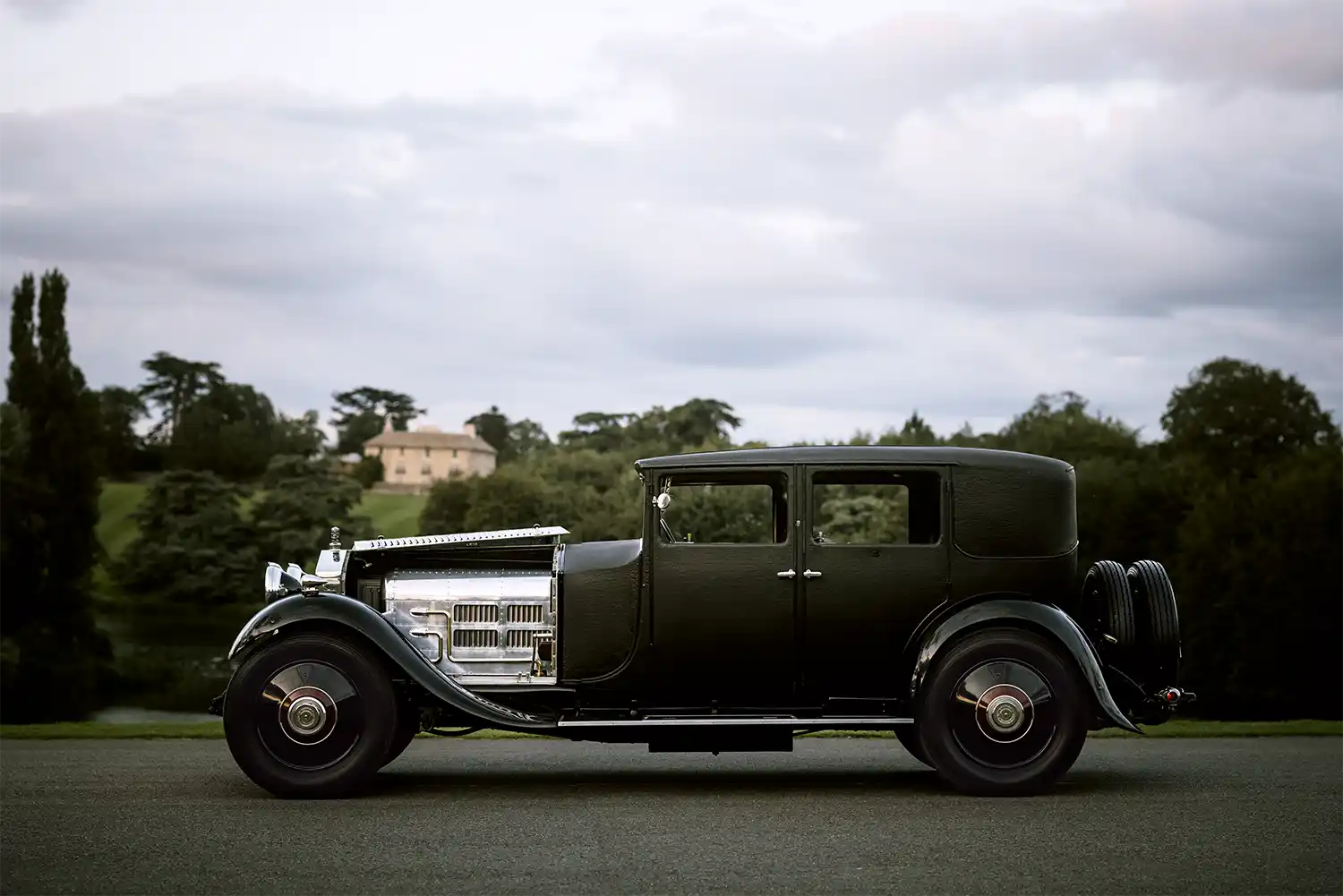

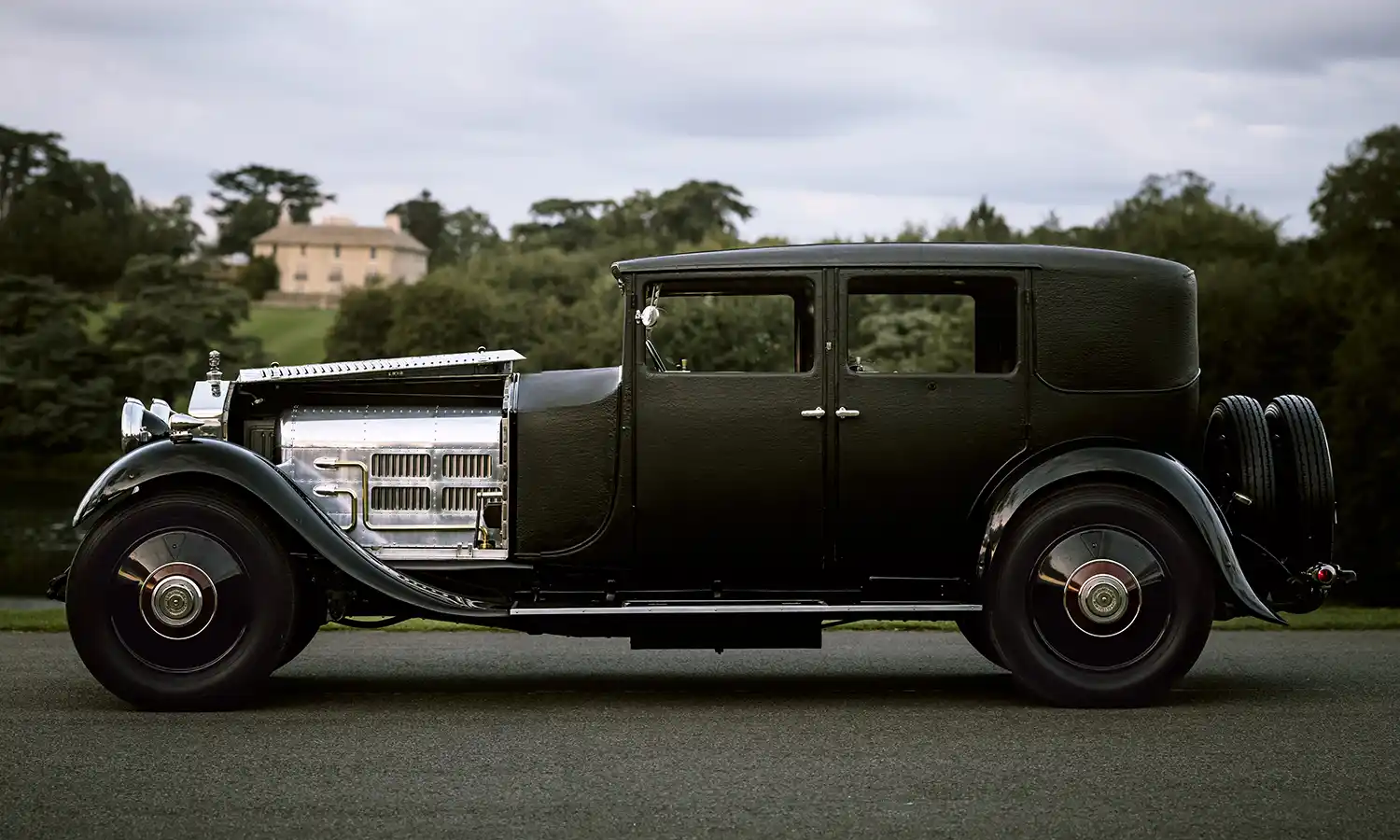

The internationally renowned British EV technology company, Electrogenic, has today revealed its latest stunning bespoke conversion, a show-stopping 1929 Rolls-Royce Phantom II with coachwork by HJ Mulliner & Co., converted to clean all-electric power. It’s the silent, effortless powertrain this stately motor car always deserved.

Commissioned by a private collector, the Phantom is making its public debut at Salon Privé, one of the world’s leading Concours events.

Thought to be the most complex classic car EV conversion yet completed, the project further underlines Electrogenic’s world-leading position in this rapidly growing sector. The project is a showcase for the Oxford based firm’s unparalleled creativity, craftsmanship and technical capabilities.

Steve Drummond, Director, Electrogenic, said: “We’re delighted to reveal this fabulous EV converted Phantom II to the world. It has been an immensely complicated and rewarding project, carried out over the course of 18 months by our team of sector-leading engineers, programmers and fabricators.

“This is undoubtedly the most complex classic car EV conversion yet attempted, the stunning results really are a testament to the world-leading talents of our team. We’re immensely proud of the results, and we’re delighted to be unveiling it at Salon Privé, here at Blenheim Palace. It’s the perfect place to reveal such a stately piece of British motoring history, now updated and future-proofed for the next hundred years of clean, silent electric motoring.”

Electrogenic, also known for its range of revolutionary ‘drop-in’ EV conversion kits for popular models – offered via an international partner-installer network – has sympathetically modernised this piece of British motoring history. One of just 1,681 Phantom IIs crafted between 1920 and 1935, it now packs a whisper-quiet, effortlessly powerful electric powertrain, featuring Electrogenic’s proprietary EV technology. The Phantom’s stunning original looks and features are retained, and as with all of Electrogenic’s projects, the conversion is entirely reversible.

Transformed Mechanicals; Ingenious Packaging

The car was originally powered by a gargantuan 7.7-litre pushrod straight-six, producing between 40 and 50bhp, bolted directly to a four-speed, non-synchromesh manual gearbox. In its standard configuration Rolls-Royce claimed a top speed of ‘well over 80mph’. Now, the petrol engine and gearbox have been carefully removed, replaced by 93kWh of batteries which have been carefully integrated into the existing structure of the car.

The batteries feed an electric motor mounted between the chassis rails via a custom single-speed direct drive transmission, delivering 150kW and 310Nm of torque to the fixed reduction gear, which in turn delivers 1,000Nm to the prop shaft. The systems are all seamlessly linked and managed by a bespoke suite of software – all developed in house by Electrogenic’s software engineers.

As with every Electrogenic conversion, the battery configuration has been tailored specifically to the model in question; housed within the car’s original architecture, no modifications are made to the structure itself. Electrogenic leads the world with its flexible battery installation systems.

It’s a carefully honed process which involves carrying out a 3D scan of the car’s structure, before rendering the optimal battery instillation setup in CAD. Thanks to its market leading battery installation capabilities, Electrogenic can precisely configure the batteries to fit the existing shape of the car, making the most of the useable space, and in turn, maximising battery capacity.

In the case of the Phantom II, Electrogenic has made use of the sizeable space vacated by the engine and gearbox, installing the batteries under the bonnet and between the chassis rails.

Showstopping Design Flair

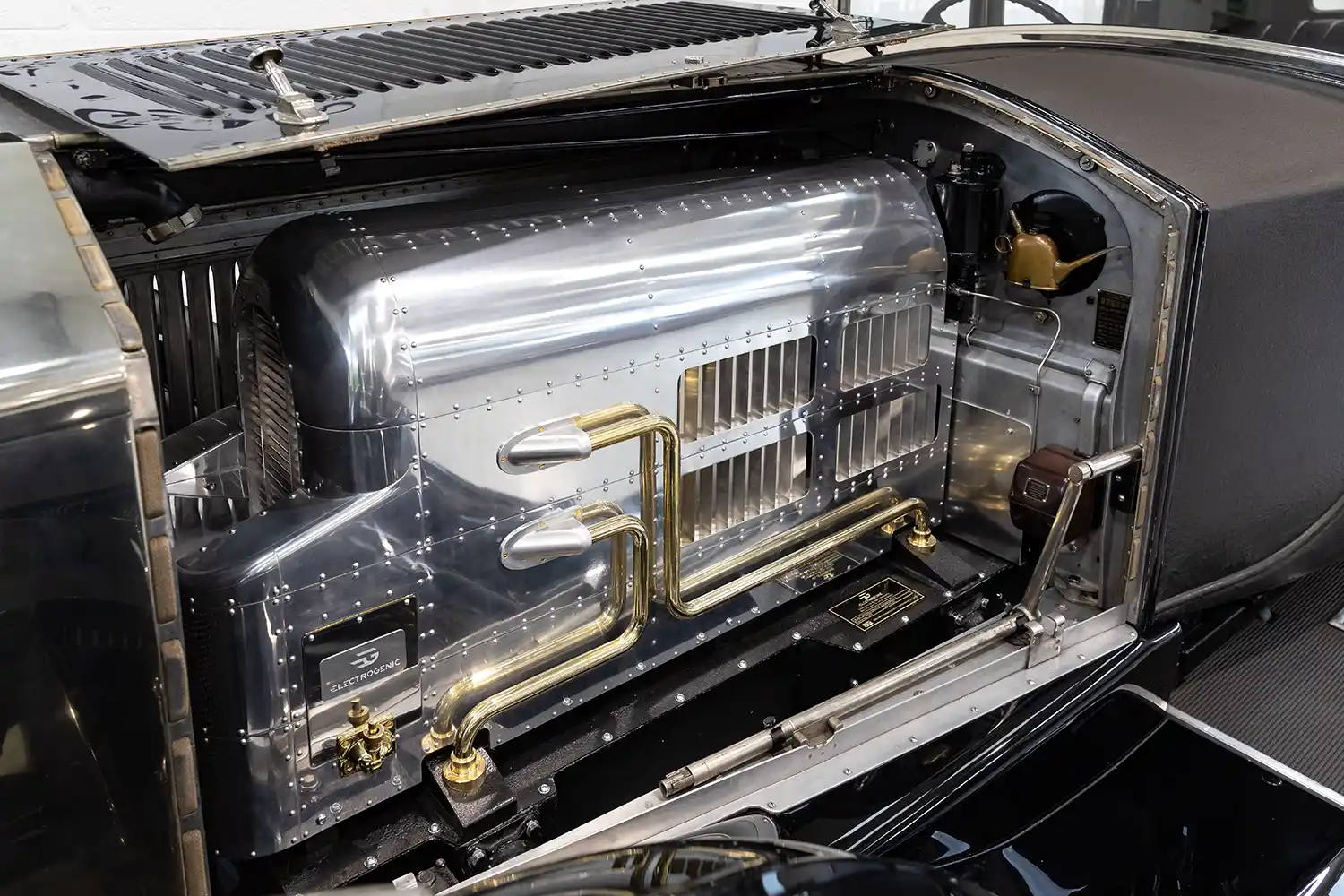

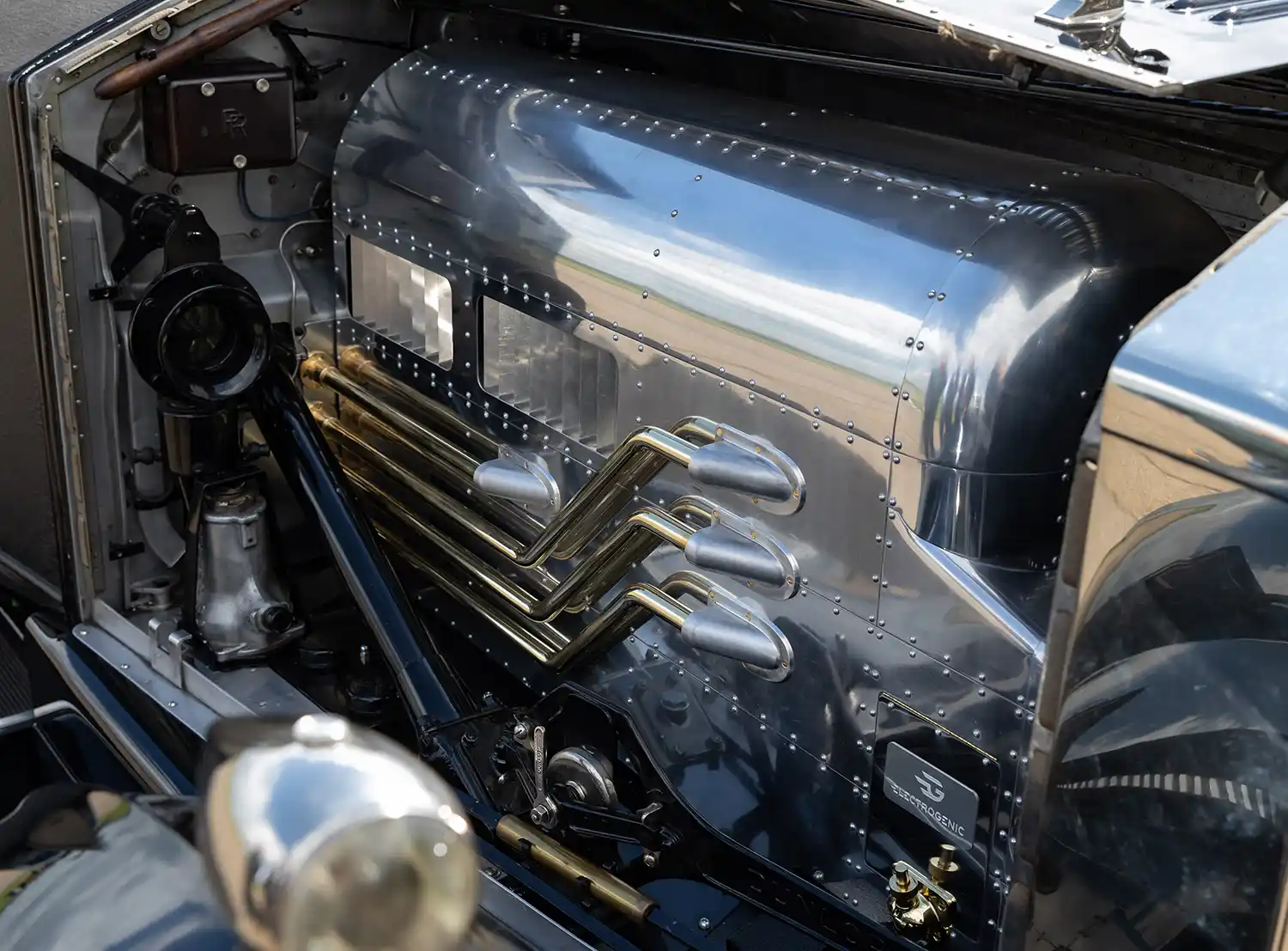

The batteries themselves are housed beneath a gleaming, hand-formed and hand-riveted aluminium cowling – a sculptural design element that delights every time you raise the Phantom’s centrally hinged bonnet.

The ornate casing has been designed by Electrogenic and constructed by the technicians at Auto Historica, affiliated with the Heritage Skills Academy at Bicester Heritage – an educational centre attended by Electrogenic’s apprentices, that is committed to giving young mechanics the professional skills to succeed in the heritage industry and preserve these wonderful machines for future generations. The battery installation and cowling perfectly illustrate the Electrogenic team’s ability to deliver a sympathetic re-engineering that combines cutting-edge technology and innovation with show-stopping design flair.

Engineering challenges; creative solutions

As one might expect, there were a number of challenges associated with sympathetically converting a near hundred-year-old, idiosyncratic luxury motor car to run on the latest EV technology. Electrogenic has used its deep reserves of engineering nous and creativity to deftly solve them.

One key challenge was devising a way to preserve and update the Phantom’s centralised, entirely mechanical, ‘through-flow’ chassis lubrication system. This is a setup that sends oil to the car’s many phosphor-bronze bushes for brake and suspension linkages, as well as other mechanical control systems – crucial to the Rolls’ trademark silken drive. The complex system was disrupted by the removal of the straight-six engine and so Electrogenic supplemented its design to ensure it continued to work as intended.

Another challenge the team faced was re-designing the original cable-operated braking system to work seamlessly with the updated EV architecture. The original brake pedal and levers sat under the bulkhead in space now taken by the large battery pack, so Electrogenic again supplemented the design of the braking system to fit the new layout. In a move that illustrates Electrogenic’s belief in creatively preserving the character of the car, the team re-positioned the original brake levers and cables – maintaining the original ratios of the mechanical balancing system, just in a new configuration.

The brakes are operated by a new pedal, with braking power amplified by a new hydraulic system installed between the new pedal and the original cable actuators. As a final touch, the Electrogenic team calibrated the brakes to work in tandem with the motor’s regen function, further enhancing braking performance while also boosting efficiency and range.

The braking system shows Electrogenic at its best: elegantly engineering old and new technology to work in harmony – preserving original features and character wherever possible while delivering transformed functionality and useability.

Discreetly Updated Interior

The programme of sympathetic updates continues inside, where Electrogenic has been careful to retain the wonderful original features of the beautifully patinaed leather and wood lined cabin. The original controls have been repurposed and the standard gauges have been creatively re-worked. The fuel gauge, originally a vertical sight glass, is now an LED state of charge gauge; the amp meter is a power gauge, showing the rate of power draw when accelerating, and power harvesting under regen; oil temperature gauge shows charger temperature and the water temperature gauge shows the temperature of the electric motor.

The modernisations also extend to the audio setup: the cabin now houses a sate of the art, high-end multi-speaker HiFi system, with integrated sub-woofer under the rear seat and full Bluetooth connectivity. All of this is discreetly hidden from view.

Driving Experience: A Phantom Transformed

The different elements add up to deliver a stunning, cohesive package. The updated machine is a delight to drive, a Phantom that performs as Rolls-Royce’s engineers of a century ago would have wanted had they possessed the requisite technology: it is silent, effortless and graceful.

While transformed in terms of performance and ease of use, as with all Electrogenic conversions, the car’s tuning and calibration – honed over countless test miles – have been carefully shaped to reflect the original character of the car. Rather than transforming it beyond all recognition, the Phantom drives like a better version of its original self.

The electrified classic is now easy to start, with smooth, quiet acceleration and no-need for double de-clutching – making it much more useable in traffic. The updated braking system effortlessly slows the two tonne Rolls, so you can drive with confidence whether in town or cruising on the open road.

The updated machine is also vastly more efficient than the original; despite its significant weight and a drag ratio of close to one, the state of the art powertrain with regen capabilities offers a range of circa 150 miles in real-world driving. Electrogenic have also engineered in different driving modes, with normal ‘Drive’, range boosting ‘Eco’ and high-performance ‘Sport’ settings. There is also a ‘regen doubler’ setting for the regenerative braking, which the driver can deploy on long, steep descents.

Drummond concluded: “We’re honoured to have been asked to build this special car for such a delightful private collector, someone who loves their cars and is deeply passionate about the environment. It’s been an immensely rewarding collaborative process with the owner, bringing our shared vision to life.

“It’s been technically challenging – from initially exploring the feasibility of the project and technical specifications, to then developing different rendered options for how we would integrate the EV componentry. This included options for how the batteries should be displayed under the bonnet. This level of choice is all part of the premium ultra-bespoke conversion service we offer clients.

“While it sounds like we’ve carried out a great deal of modifications – and we have – I’m particularly proud of the fact that, as with all Electrogenic conversions, nothing has been drilled or cut on the car. All the parts can be reassembled, and the car returned to its original state, if required.

“This really has been a fascinating project to work on, and one that we’ve poured our hearts and souls into. We’re delighted with the results; it combines the most stunning 1920s coachbuilding with an updated driving experience that’s entirely befitting of a Rolls-Royce. Every single member of the Electrogenic team has contributed to this project and we are all proud to have added our mark to this remarkable motor car, readying it for a further hundred years of dignified, stately – and now clean – motoring.”

Background: Cutting Edge Technology, Developed in Britain

Electrogenic’s conversions – whether bespoke conversions or its’ popular range of ‘drop-in’ kits – feature the firm’s sector-leading, proprietary EV technology – the tech that has underpinned the company’s rapid rise and sustained growth in recent years.

All Electrogenic conversions are defined by their quality and depth of engineering, using technology developed in-house by a research and development team comprising leading automotive engineers, programmers and electrical experts.

Each conversion reflects Electrogenic’s approach of developing and manufacturing its own technology, which includes in-house designed software, printed circuit boards (PCBs) and digital dashboards, as well as vehicle management technology that can integrate any of the latest motors, battery modules, etc. to incorporate the best new tech into its conversion packages.

The conversions use highly innovative mechanical componentry, including a unique system for creating high-density battery packs, as well as exceptionally compact in-line and transverse reduction gearboxes, all manufactured in the UK. The cleverly packaged conversions always ensure that the existing vehicles’ existing structure and architecture is preserved. This approach ensures that all Electrogenic conversions are entirely reversible.

Electrogenic’s world-leading bespoke conversions are completed at Electrogenic’s Oxford HQ and workshop, while the ‘drop-in’ kit range is offered internationally through a rapidly-growing network of partner installers. Learn more about the ‘plug-and-play’ kit range here: https://www.electrogenic.co.uk/conversion-kits